A construction method of widening road base

A construction method and technology for highway bases, applied in roads, roads, buildings, etc., can solve the problems of non-dense joints, poor compaction quality, lack of experience, etc., to avoid potential safety hazards, improve health effects, and improve compaction. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

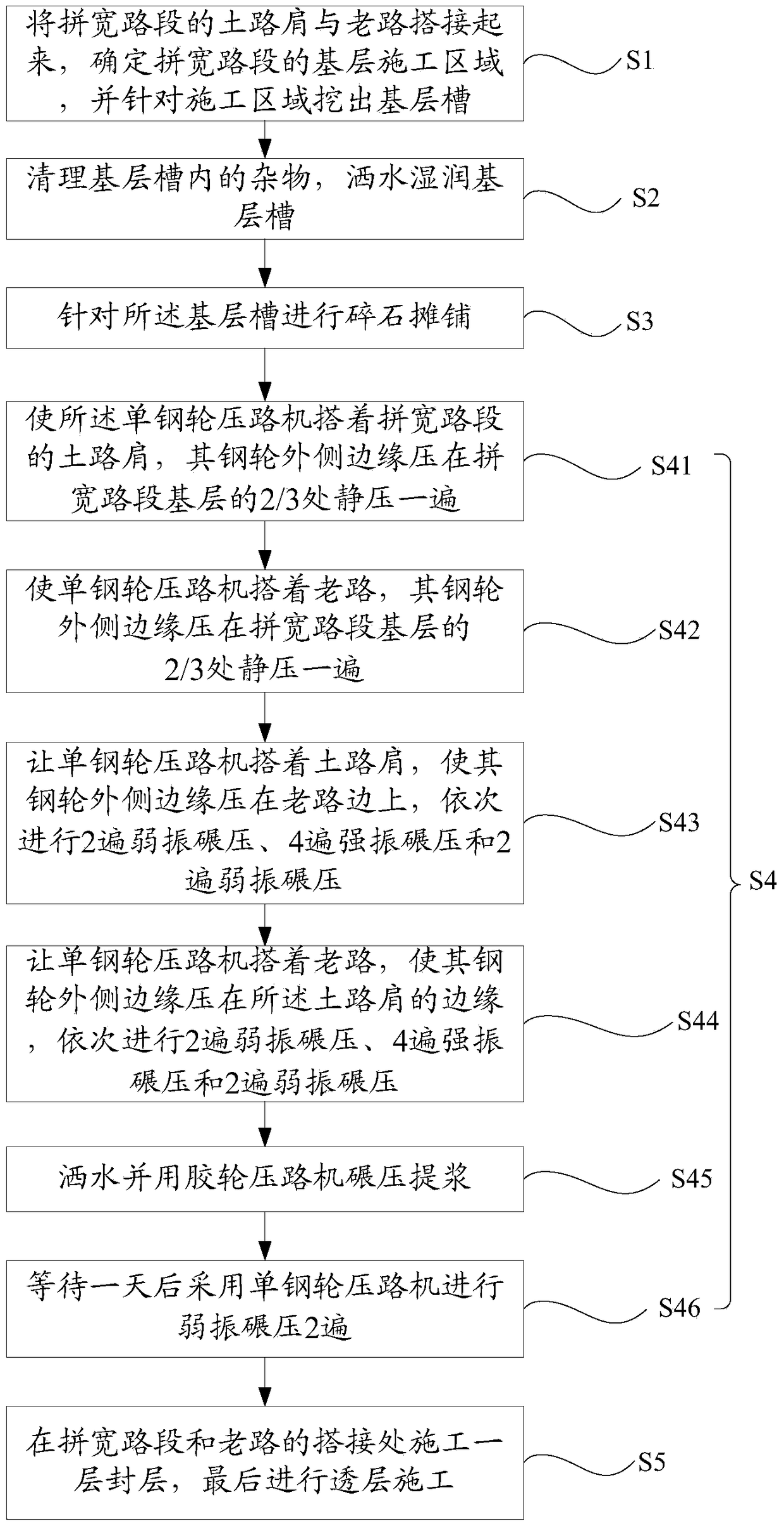

[0030] Such as figure 1 As shown, the present invention provides a kind of widening construction method of highway base, comprising the following steps:

[0031] S1: Lap the soil road shoulders of the widened road section with the old road, determine the base construction area of the widened road section, and dig out base grooves for the construction area; After compaction, use the method of spreading ash line to delineate the construction scope of the base layer of the widened road section; preferably, when digging the base layer groove, the line shape must be kept straight, so as to facilitate subsequent paving and rolling operations , improve work efficiency and construction effect, and excavate the original grassroots part with quality defects at the edge of the old road, so as not to affect the grassroots construction of the splicing road section. In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com