Device for milling round pit on asphalt pavement

A technology of asphalt pavement and milling, which is applied in the direction of roads, roads, road repair, etc., to improve the quality and service life of pavement maintenance, overcome the overall poor quality, and facilitate the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

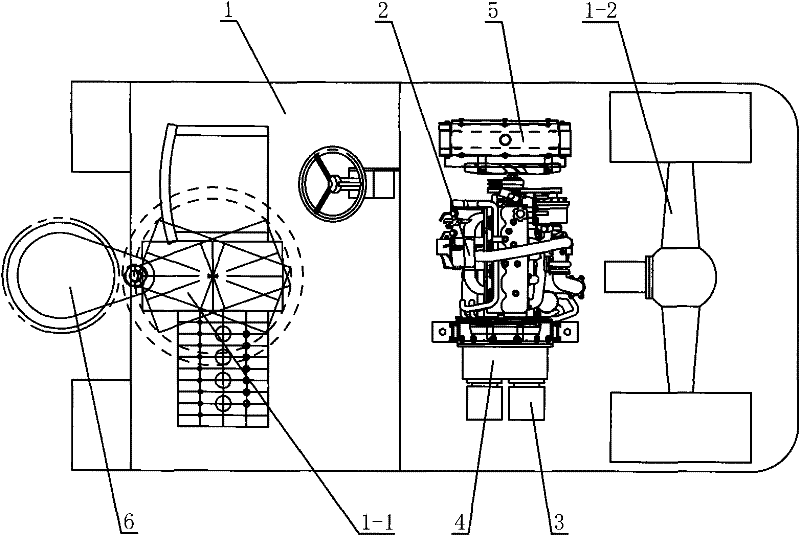

[0040] like figure 1 and figure 2The shown a kind of asphalt pavement circular pit milling equipment includes a self-propelled chassis 1 and an engine 2 installed on the self-propelled chassis 1, a hydraulic oil pump group 3, a transfer case 4 and a box assembly 5, the The engine 2 is installed in the middle of the self-propelled chassis 1, the transfer case 4 is installed at the output end of the flywheel of the engine 2, the hydraulic oil pump group 3 is installed at the output end of the transfer case 4, and the box assembly 5 is installed at the The left side of the engine 2 also includes a rotary lifting vertical milling device 6, and the rotary lifting vertical milling device 6 is installed on the self-propelled chassis 1 rear portion. Wherein, the rotary lifting vertical milling device 6 includes a cylinder 6-1, a lifting piston 6-2, a lifting piston rod 6-3, a milling mandrel 6-4, a milling hydraulic motor 6-5 and a milling cutter Disk 6-6, the lifting piston 6-2 an...

Embodiment 2

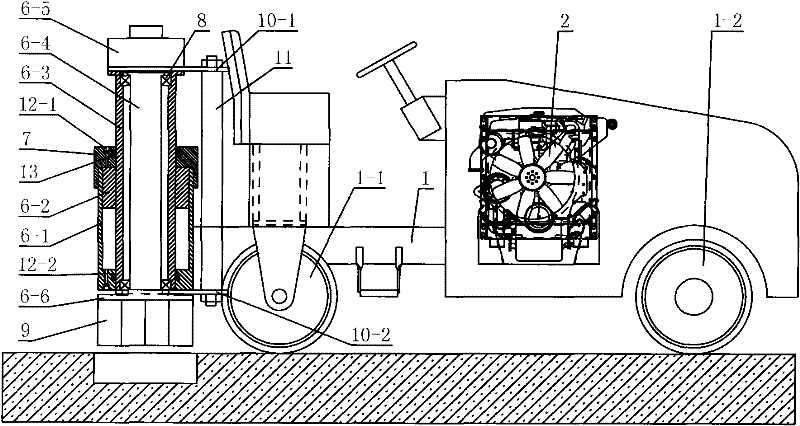

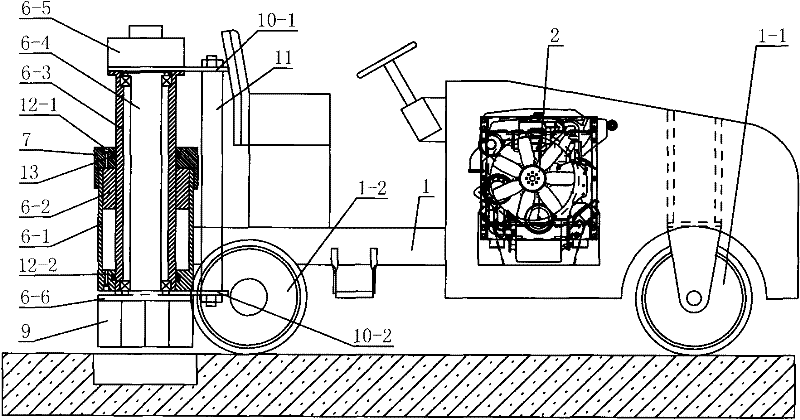

[0045] Such as image 3 with Figure 4 The shown a kind of asphalt pavement circular pit milling equipment includes a self-propelled chassis 1 and an engine 2 installed on the self-propelled chassis 1, a hydraulic oil pump group 3, a transfer case 4 and a box assembly 5, the The engine 2 is installed in the middle of the self-propelled chassis 1, the transfer case 4 is installed at the output end of the flywheel of the engine 2, the hydraulic oil pump group 3 is installed at the output end of the transfer case 4, and the box assembly 5 is installed at the The left side of the engine 2 also includes a rotary lifting vertical milling device 6, and the rotary lifting vertical milling device 6 is installed on the self-propelled chassis 1 rear portion. Wherein, the rotary lifting vertical milling device 6 includes a cylinder 6-1, a lifting piston 6-2, a lifting piston rod 6-3, a milling mandrel 6-4, a milling hydraulic motor 6-5 and a milling cutter Disk 6-6, the lifting piston 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com