Concrete laser leveling machine

A laser leveling machine and concrete technology, which is applied in the fields of construction, building structure, and building materials, can solve the problems of unsatisfactory concrete floor flatness, low floor operation efficiency, and poor floor compaction effect, etc., to achieve Good compaction effect, high floor operation efficiency, and the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

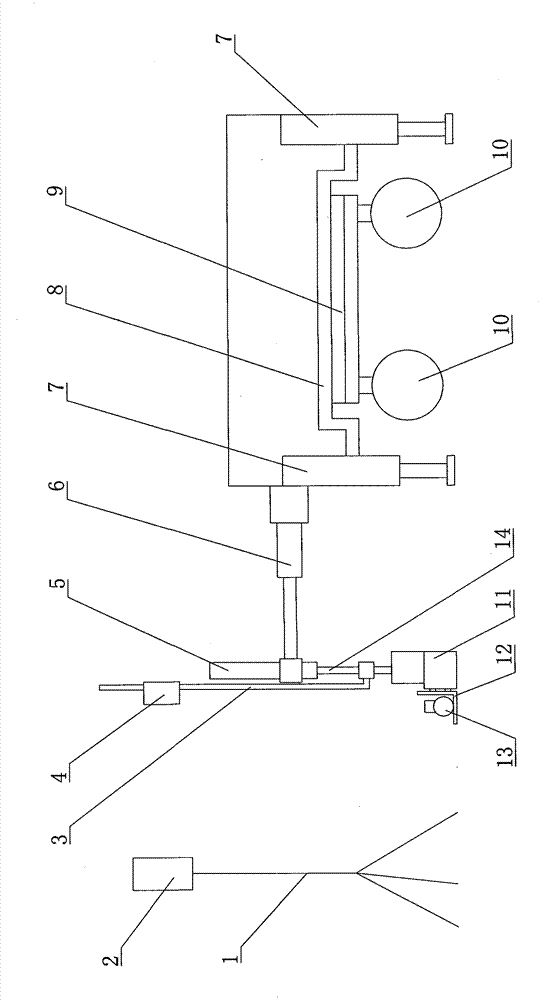

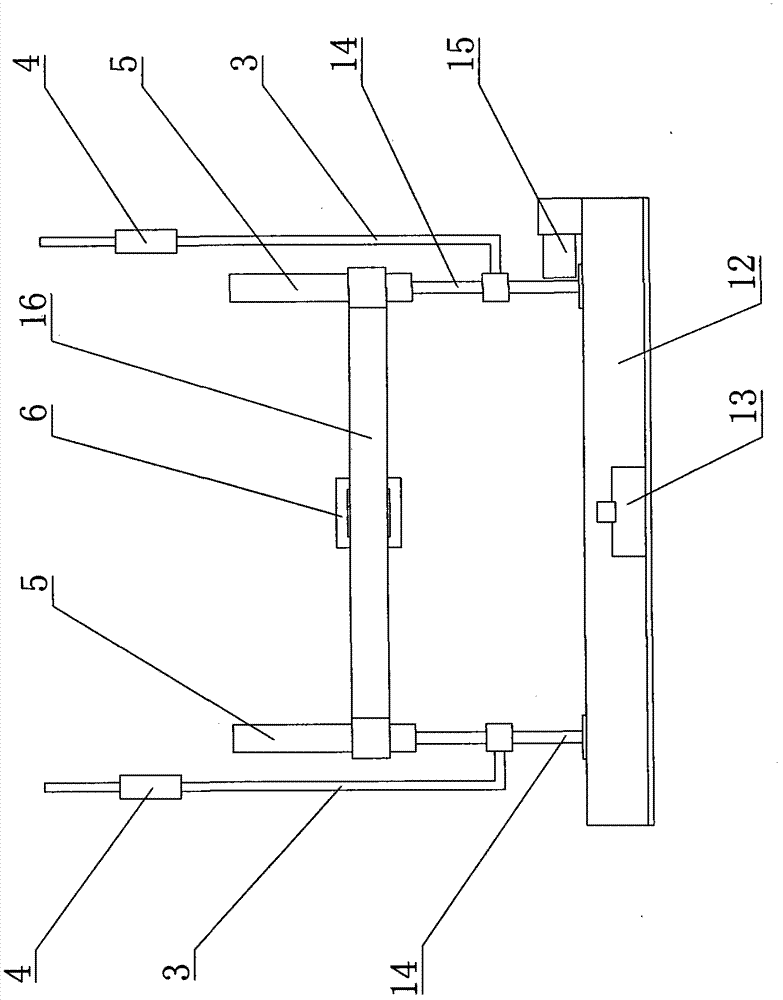

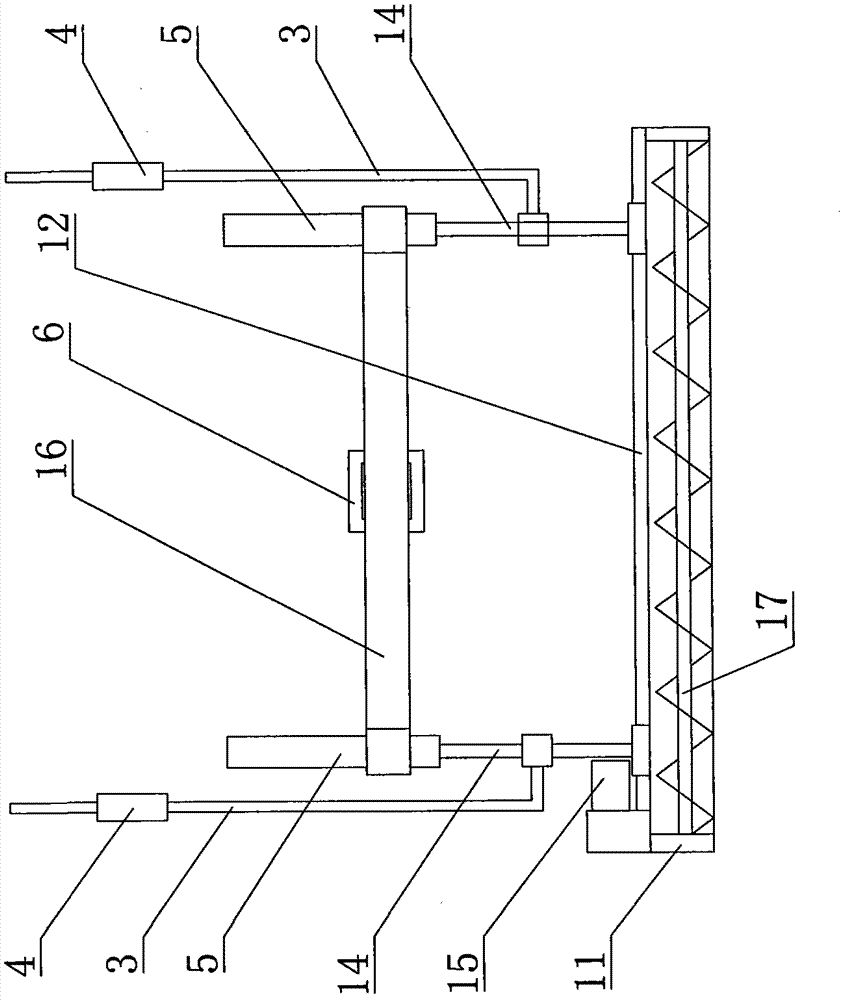

[0020] Example: as attached figure 1 to attach Figure 4 As shown, the concrete laser leveling machine includes a frame 8, a laser system and a computer control system, the laser system includes a laser receiver 4 and a laser transmitter 2, the computer control system is electrically connected to the laser receiver 4, and the frame 8 is connected to There is an engine and an oil pump connected to the transmission of the engine. The four corners of the frame 8 are connected with hydraulic outriggers 7 . The lower part of the frame 8 is connected with a rotary platform 9 . The driving device includes a slewing hydraulic motor, which is connected to the slewing support in transmission, and the lower part of the slewing platform 9 is connected to a traveling wheel 10, and the traveling wheel 10 is connected to a traveling hydraulic motor 18 through transmission;

[0021] The frame 8 is connected with a hydraulic telescopic rod 6, and the end of the hydraulic telescopic rod 6 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com