Three-shaft linkage block eccentric linear vibrating screen

A technology of linear vibrating screen and three-axis linkage, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of increasing the vibration mass, increasing the load of the equipment foundation, and small vibration force, so as to reduce the height of the unit and reduce the vibration. The effect of high frequency and large excitation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

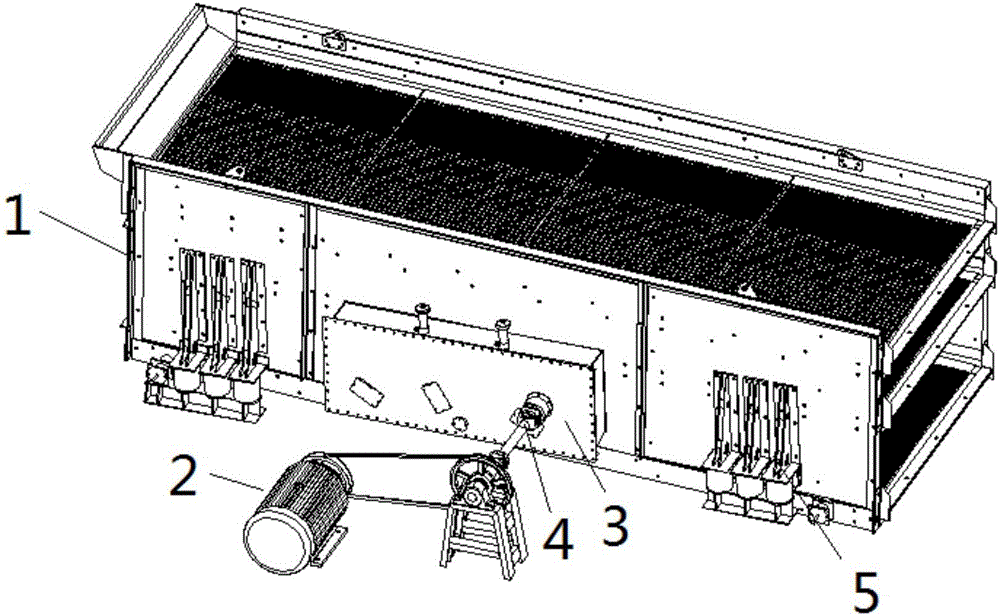

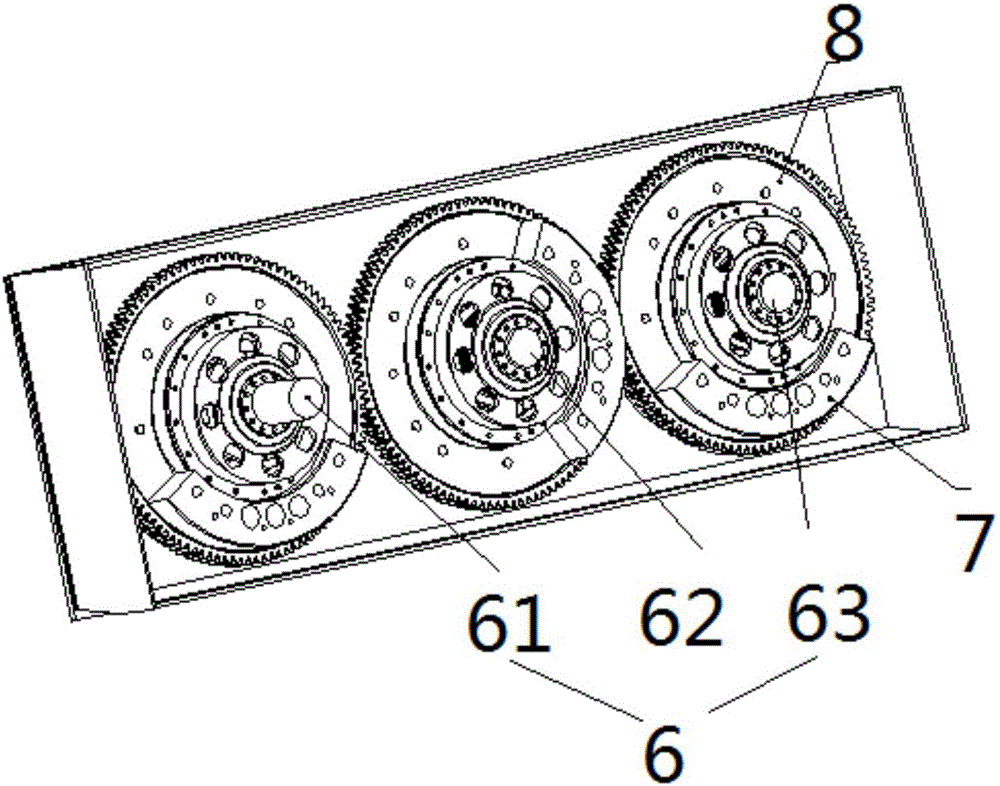

[0020] Such as figure 1 and figure 2 Shown: a three-axis linkage block eccentric linear vibrating screen, including a screen box 1, a motor 2, an eccentric block gearbox 3, a universal coupling 4, and a rubber spring 5, and the eccentric block gearbox is provided with a first linear vibrating screen in sequence. Through shaft 61, the second through shaft 62 and the third through shaft 63, both ends of the first through shaft, the second through shaft and the third through shaft are symmetrically provided with spur gear 8 and eccentric block 7, the first through The shaft, the second through shaft and the third through shaft are meshed and driven by the spur gear 8 . The advantage of the spur gear transmission is to ensure the synchronous excitation of the eccentric block, the excitation force is large, and the amplitude is high. The structure of the spur gear eccentric block makes the machine produce an ideal linear reciprocating motion, realizes horizontal installation, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com