Inertia force vibration exciter

A vibration exciter and inertial force technology, applied in the field of vibration devices, can solve the problem of excessive weight of the ultra-low frequency exciter, the inability of the rotating eccentric mass exciter to perform ultra-low frequency excitation of super-large structures, and single-direction excitation, etc. problems, to achieve the effect of improving versatility, reducing failures, and compact transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

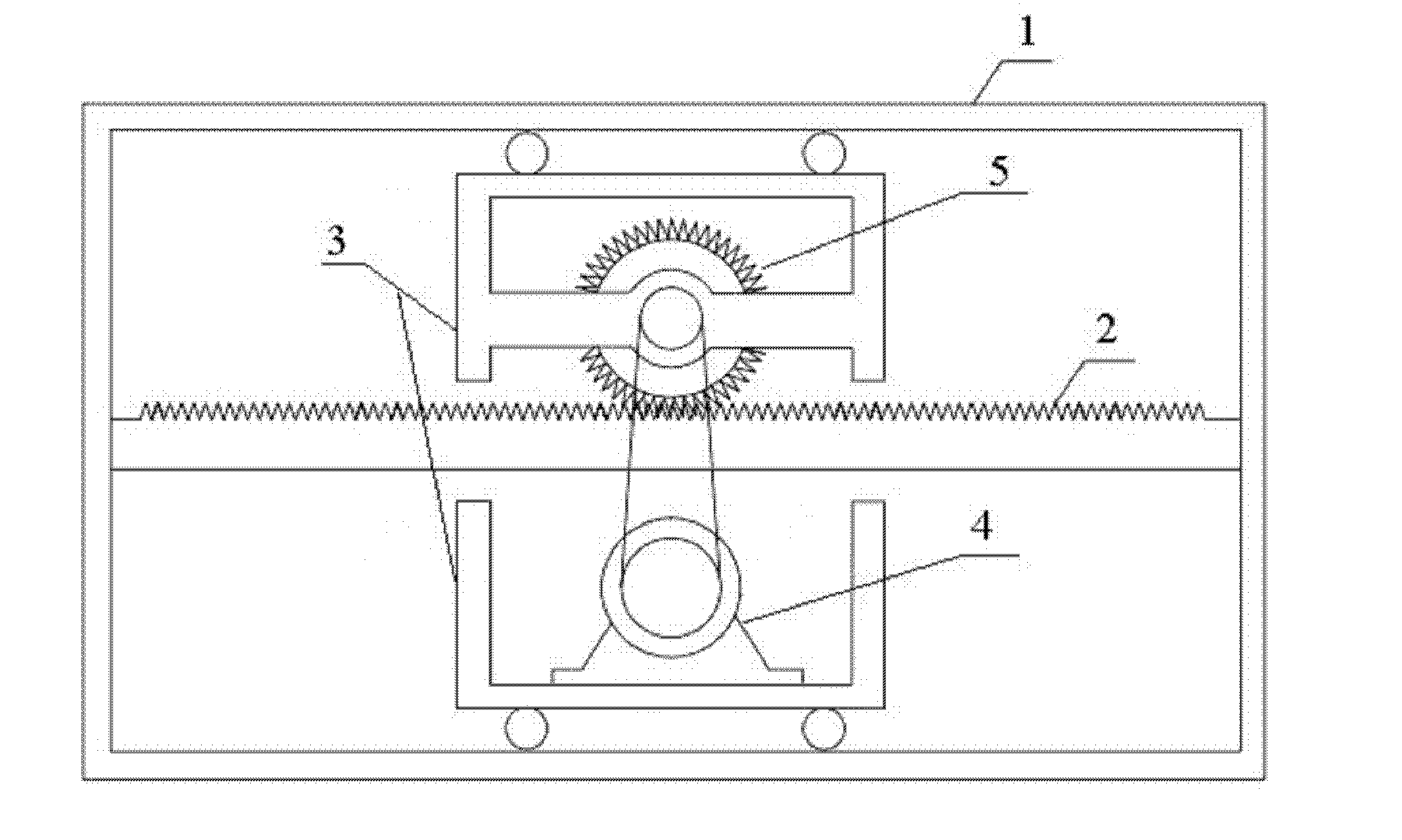

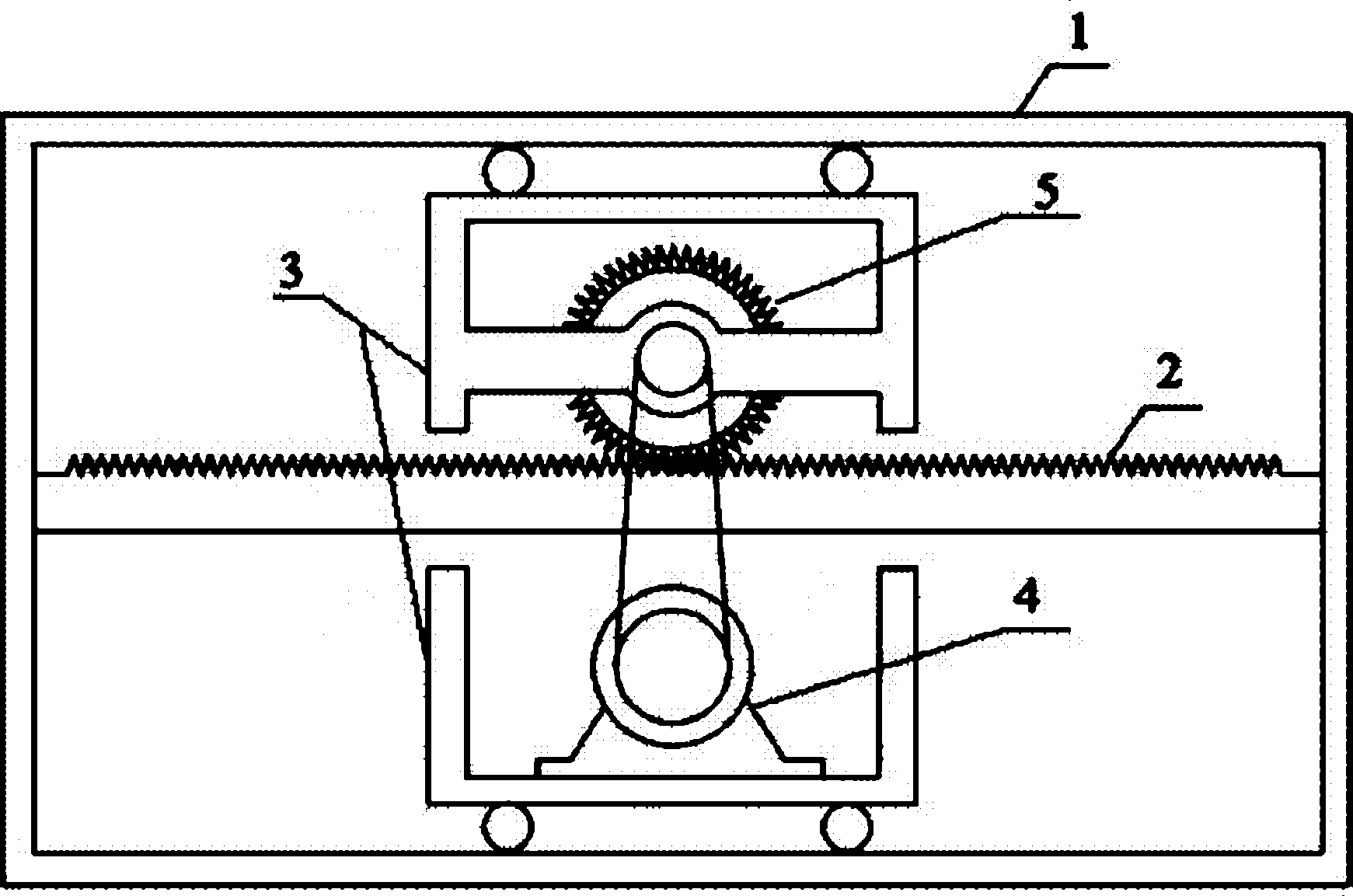

[0022] Such as figure 1 As shown, the exciter includes a support and guide frame 1 with a track 2 inside, a moving mass block 3 arranged inside the support and guide frame 1, a drive system composed of a drive device and a transmission device connected to the drive device; The driving system is installed inside the moving mass block 3, and drives the moving mass block 3 to reciprocate along the track 2; the driving device includes a driving motor 4 with a speed reducer, and the driving motor 4 with a speed reducer is a numerical control motor; the transmission device It includes a driving wheel 5 fixed in the moving mass block 3, and the driving wheel 5 is placed on the track 2, wherein the driving wheel 5 is a gear, and the track 2 is a rack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com