Gear shock excitation mechanism

A vibration-exciting mechanism and gear technology, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of reduced service life, vibration bearing can not bear the excitation force, etc., to reduce oil temperature, bearing load The effect of increased capacity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

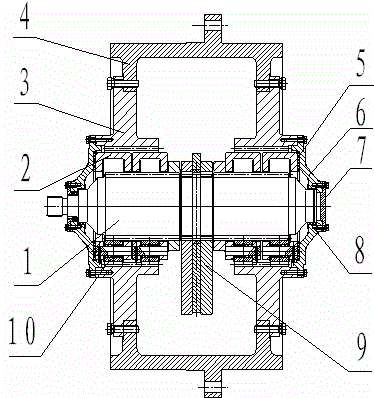

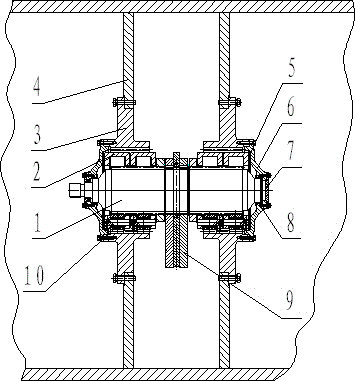

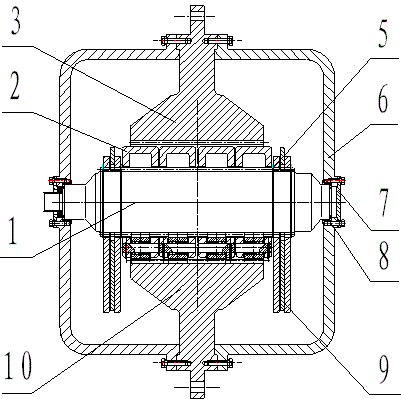

Image

Examples

Embodiment 1

[0027] Embodiment 1: The gear excitation mechanism has a sun gear shaft 1, one end of the sun gear shaft 1 is connected to the external drive mechanism through a spline, the two ends of the sun gear shaft 1 are connected to the large end cover 6 through a sliding bearing 8, and the sun gear shaft 1 is connected to the large end cover 6. There are gears; the sun gear shaft 1, the planetary gear 10 and the inner gear 3 mesh with each other, the outer end of the inner gear 3 is connected with the working device 4, and the planetary gear 3 is installed on the planetary gear frame 2; the center hole of the fixed eccentric block 21 is the inner Gear is contained on the sun gear shaft 1 and is integrated with the sun gear shaft 1. The sliding sleeve center hole is the sliding sleeve internal gear 23, and the movable eccentric block 22 is contained on the outer circle of the sliding sleeve, and the movable eccentric block 22 can rotate around the sliding sleeve.

[0028] There are 4 pl...

Embodiment 2

[0042] Embodiment 2: The planetary gear mechanism can be installed in the box to become an independent gear vibration mechanism, and there are retaining rings between the planetary gear frames, both of which play the role of isolating adjacent parts. Sliding bearings are installed at both ends of the sun gear shaft. The working device is a wheel, and an oil filling hole is arranged on the working device.

[0043] There are 2 planetary gear carriers 2, and there are retaining rings between every two planetary gear carriers; there are 3 to 6 planetary gears in each planetary gear carrier, and the planetary gears are installed on the planetary wheel carrier through shafts. Sliding bearings are installed on the shaft, and the end covers on both sides are installed on the inner gear.

[0044] A fixed eccentric block casting is installed on the sun gear shaft, and is separated from the planetary gear carrier by a retaining ring.

[0045] Other embodiment 1 is the same.

Embodiment 3

[0046] Embodiment 3: The eccentric mass mechanism is located on both sides of the planetary drive train. There are many sets of star gear mechanisms between the eccentric block mechanisms.

[0047] There are 6 planetary gear carriers 2, and there are retaining rings between every two planetary gear carriers; there are 3 to 6 planetary gears in each planetary gear carrier, and the planetary gears are installed on the planetary wheel carrier through shafts. Needle rollers or bearings or sliding bearings are installed on the shaft, and the end covers on both sides are installed on the inner gear. There is a gap between every two planetary gear carriers, and there is no gear ring. A sliding sleeve is arranged in the center hole of the fixed eccentric block.

[0048] The working device is a casing, and there is an oil filling hole on the working device.

[0049] Other embodiment 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com