Novel vibrating screen based on multi-motor frequency conversion excitation

A vibrating screen, multi-motor technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of non-adjustable excitation frequency, environmental protection, mud splashing, etc., to achieve energy-saving service life, prolong service life, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

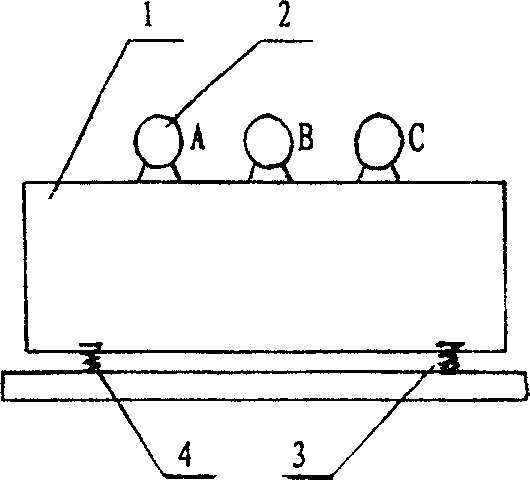

[0022] See attached figure 1 , attached figure 2 . The new vibrating screen based on the multi-motor excitation mode is mainly composed of a screen box 1, a vibrator 2 and a base 3. The screen box 1 is installed on the base by a vibration isolation spring 4, and the vibrator uses three elongated vibration motors A , B, and C are installed at appropriate positions on the top of the screen box 1. Each vibration motor can have different eccentric masses according to actual needs. Vibrating motors B and C rotate in the same direction, and the resultant force of the generated vibrating force and the vibrating force generated by vibrating motor A are combined to form the vibrating force of the vibrating screen. The rotation direction of the vibration motor A is opposite to that of the vibration motors B and C.

[0023] The vibrating screen installed in this way can generate greater excitation force without increasing the excitation frequency, making the screening and conveying ...

Embodiment 2

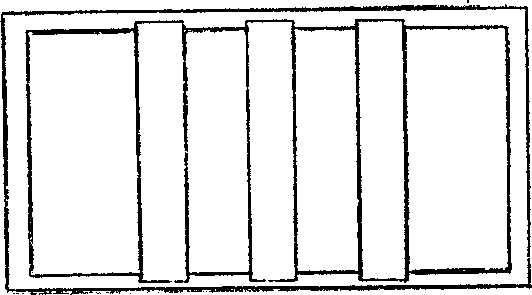

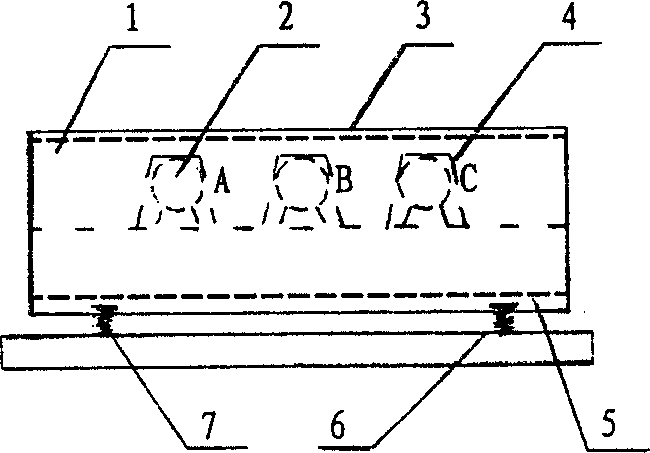

[0025] See attached image 3 , attached Figure 4 . The new vibrating screen based on the multi-motor excitation mode is mainly composed of a screen box 1, a vibrator 2 and a base 3. The screen box 1 is installed on the base by a vibration isolation spring 4, and the vibrator uses three short-shaped vibration motors A , B, and C are installed in the middle of the screen box 1 (between the upper screen 6 and the lower screen 5 ), and the protective cover 7 of the vibrator is used to prevent the filtrate of the upper screen 6 from polluting the vibrator. The excitation motor can have different eccentric masses according to actual needs. Vibrating motors B and C rotate in the same direction, and the resultant force of the generated vibrating force and the vibrating force generated by vibrating motor A are combined to form the vibrating force of the vibrating screen. The rotation direction of the vibration motor A is opposite to that of the vibration motors B and C.

[0026] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com