Vibration box of brick making machine

A technology of block forming machine and vibrating box, which is applied in ceramic forming machines, manufacturing tools, etc., can solve the problems of small eccentricity, large starting resistance distance, and long starting time of eccentric shaft vibrating box, so as to shorten the molding cycle. , The effect of small starting resistance distance and short stop vibration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

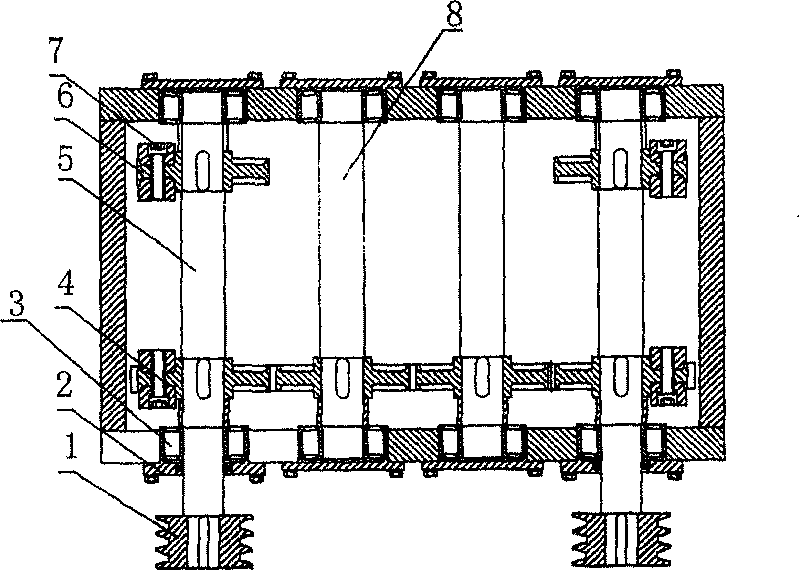

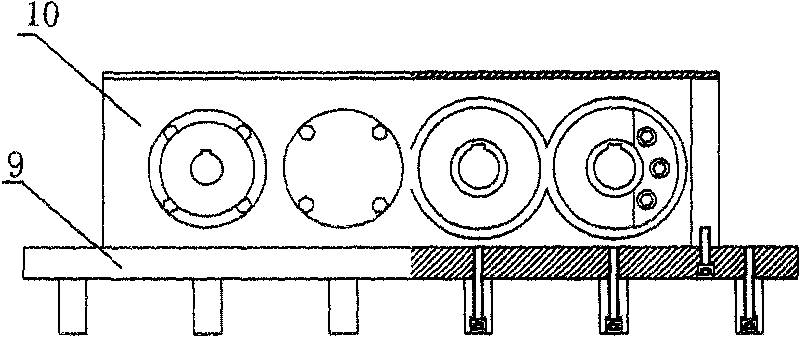

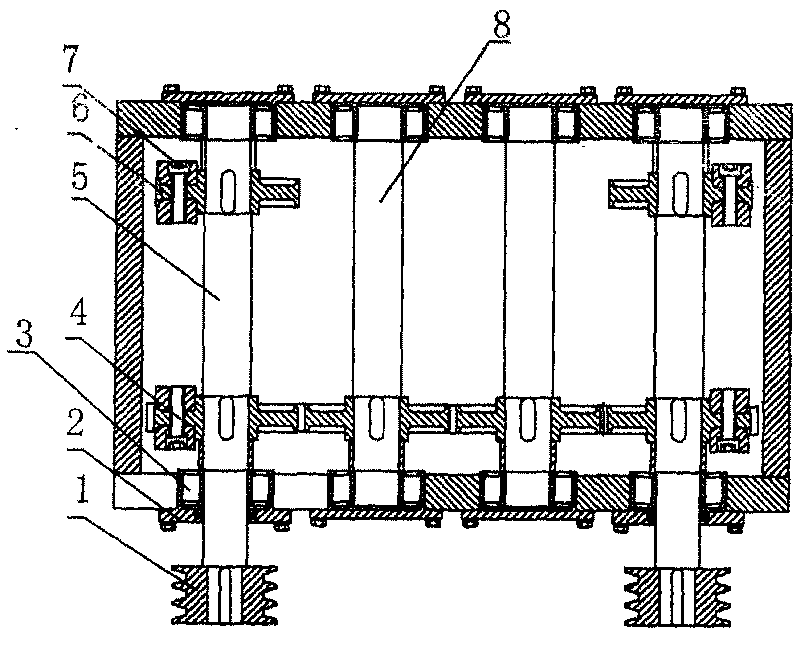

[0017] Such as figure 1 , figure 2 As shown, the vibration box of the block forming machine includes a vibration box 10 fixed on the vibration platform 9, the box 10 is equipped with two main shafts 5 and two transmission shafts 8, and one end of the two main shafts 5 passes through the box , a belt pulley 1 is provided at its end, and two transmission shafts 8 are located on the inner sides of the two main shafts 5. A synchronous gear 4 is respectively installed on the main shaft 5 and the transmission shaft 8, and is meshed with each other to realize the two main shafts The synchronous reverse rotation of the two main shafts 5 is equipped with a flange 6 respectively, and two M16 socket head cap screws are respectively fixed on the two sides of each synchronous gear 4 and flange 6. Eccentric block7. Bearings 3 are arranged at the joints between the ends of the main shaft 5 and the transmission shaft 8 and the vibration box 10 , and an oil seal 2 is provided on the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com