Low-density automobile back door plate module and preparation method thereof

A rear door panel, low-density technology, applied in the field of auto parts, can solve the problems of increasing product manufacturing costs, long molding cycle, and unfavorable design concepts for lightweight automobiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

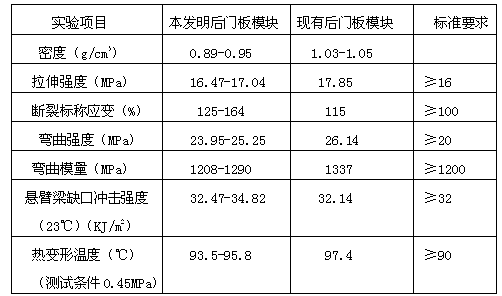

Examples

Embodiment 1

[0017] Embodiment 1: Modified polypropylene particles weigh raw materials according to the following proportions: 60 KG of polypropylene base material, 20 KG of talcum powder, 1 KG of impact modifier, 2 KG of slip agent, 0.4 KG of antioxidant, and Stabilizer 0.4 KG, UV absorber 0.2 KG, inorganic toner 2 KG. The foaming masterbatch weighs the raw materials according to the following proportions: 60 KG of high-pressure polyethylene, 4 KG of ethylene-vinyl acetate copolymer, 10 KG of talcum powder, 6 KG of foaming agent, 0.6 KG of silane coupling agent, and 0.4 KG of antioxidant KG. Prepare 3mm×5mm columnar modified polypropylene granules and 3mm×3mm foam masterbatch granules by twin-screw blending extrusion granulation respectively, and weigh them according to the ratio of modified polypropylene granules: foam masterbatch granules 100:1 Take the above two granules.

Embodiment 2

[0018] Embodiment 2: Modified polypropylene particles weigh raw materials according to the following proportions: 65 KG of polypropylene substrate, 20 KG of talcum powder, 5 KG of impact modifier, 2 KG of slip agent, 0.4 KG of antioxidant, and Stabilizer 0.4 KG, UV absorber 0.2 KG, inorganic toner 2 KG. The foaming masterbatch is weighed according to the following ratio of raw materials: high-pressure polyethylene 65 KG, ethylene-vinyl acetate copolymer 10 KG, talcum powder 10 KG, foaming agent 7 KG, silane coupling agent 0.6 KG, antioxidant 0.4 KG. Prepare 3mm×5mm columnar modified polypropylene granules and 3mm×3mm foam masterbatch granules by twin-screw blending extrusion granulation respectively, and weigh them according to the ratio of modified polypropylene granules: foam masterbatch granules 100:2 Take the above two granules.

Embodiment 3

[0019]Embodiment 3: Modified polypropylene particles weigh raw materials according to the following ratio: 74 KG of polypropylene substrate, 20 KG of talcum powder, 15 KG of impact modifier, 2 KG of slip agent, 0.4 KG of antioxidant, and Stabilizer 0.4 KG, UV absorber 0.2 KG, inorganic toner 2 KG. The foaming masterbatch weighs raw materials according to the following ratio: high-pressure polyethylene 70 KG, ethylene-vinyl acetate copolymer 19 KG, talc powder 10 KG, foaming agent 9 KG, silane coupling agent 0.6 KG, antioxidant 0.4 KG . Prepare 3mm×5mm columnar modified polypropylene granules and 3mm×3mm foam masterbatch granules by twin-screw blending extrusion granulation respectively, and weigh them according to the ratio of modified polypropylene granules: foam masterbatch granules 100:4 Take the above two granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com