Polypropylene series resin composite foam particle, and preparation method and application thereof

A polypropylene resin and composite foaming technology, applied in the field of foaming materials, can solve the problems of high molding pressure, high production cost, long molding cycle, etc., and achieve the effects of shortened molding cycle, simple preparation method and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

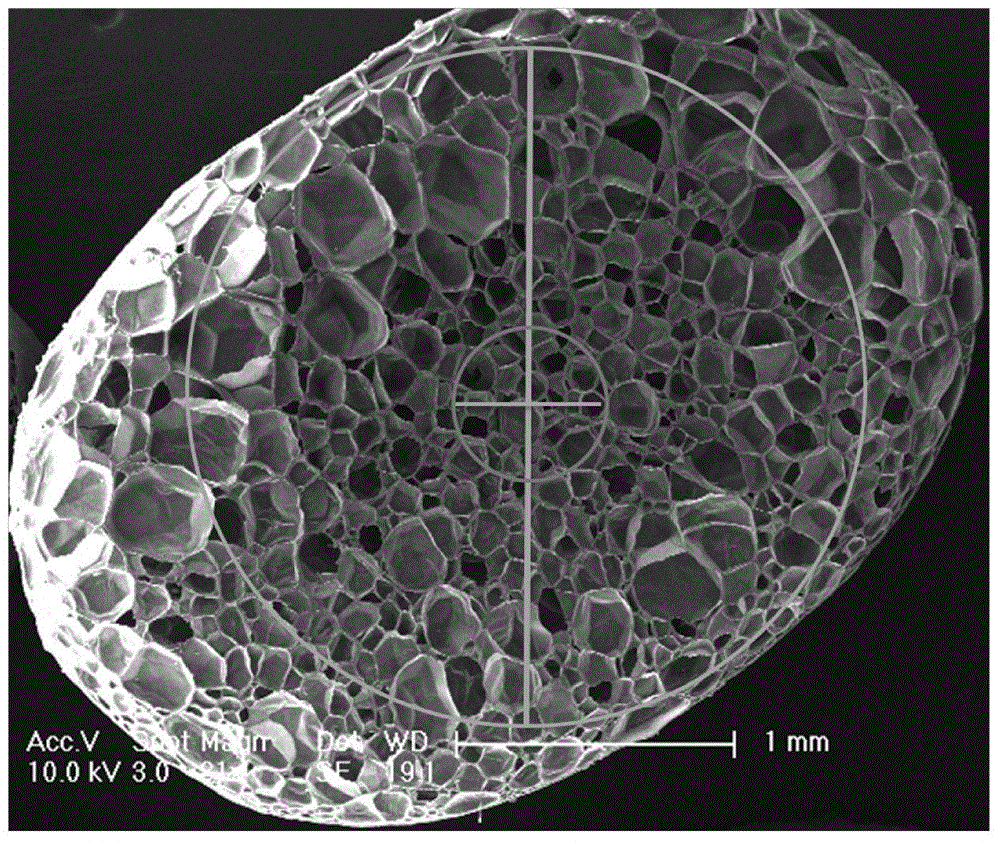

Image

Examples

preparation example Construction

[0032] The preparation method of the above-mentioned polypropylene-based resin composite foamed particles comprises the following steps:

[0033] Step 1. After mixing the matrix resin and the inorganic release agent evenly, add them to the extruder, melt and co-extrude them linearly, cool, and pelletize to obtain blended resin particles;

[0034] Wherein, there is no restriction on the mixing method of the matrix resin and the inorganic release agent, as long as the mixture is uniform, such as solution mixing or in-situ mixing; when the blended resin particles also contain additives, the additive, matrix resin and inorganic release agent Mix together, or replace the matrix resin with the matrix resin modified by additives, and keep other operations unchanged;

[0035] The extruder can be a twin-screw extruder or a single-screw extruder, and the extrusion temperature can be above the melting point of the matrix resin;

[0036]Step 2. Add the blended resin particles, foaming ag...

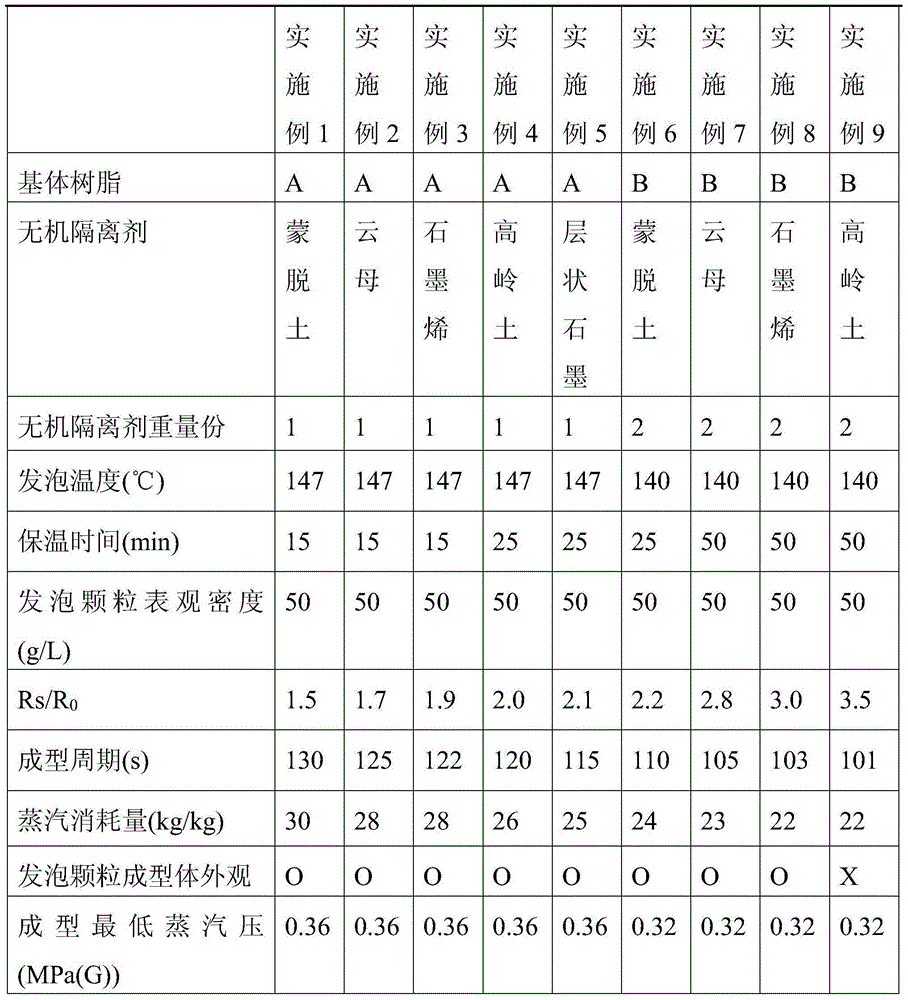

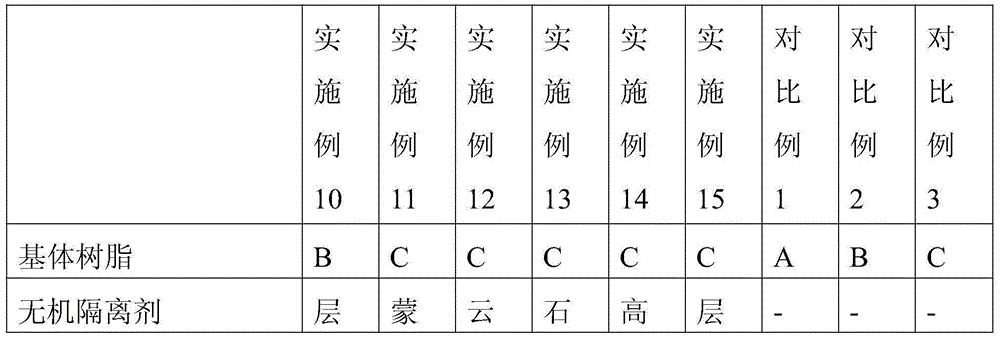

Embodiment 1-15

[0041] Preparation of polypropylene-based resin composite foam particles:

[0042] Step 1. According to the composition and proportion of Table 1 and Table 2, add 100 parts by weight of matrix resin and inorganic release agent to the extruder, melt extrude, cool, and pelletize to obtain a diameter of 1mm and a length of 1.8mm. , with an average weight of 1.8 mg blended resin particles;

[0043] Step 2, in the autoclave of 5L, add 100 weight parts (1000g) above-mentioned blended resin particle, 300 weight parts water, 0.05 weight part sodium dodecylbenzene sulfonate, 0.3 weight part kaolin and carbon dioxide (charged carbon dioxide Ensure that the pressure in the autoclave at the foaming temperature is 6MPa), heat up to a temperature 5°C lower than the foaming temperature of the corresponding Table 1 and Table 2 while stirring, keep the temperature for 15min, and then use the values in Table 1 and Table 2 respectively Foaming temperature and foaming time, make the foaming ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com