Multi-dimensional force sensor dynamic experiment device based on stable-state sine exciting force

A technology of multi-dimensional force sensor and experimental device, applied in the field of multi-dimensional force sensor dynamic experimental device, can solve the problems of calculation method error, large interference influence, difficult adjustment, etc., and achieve single and stable frequency components, little influence of power supply fluctuation, and mechanical noise. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

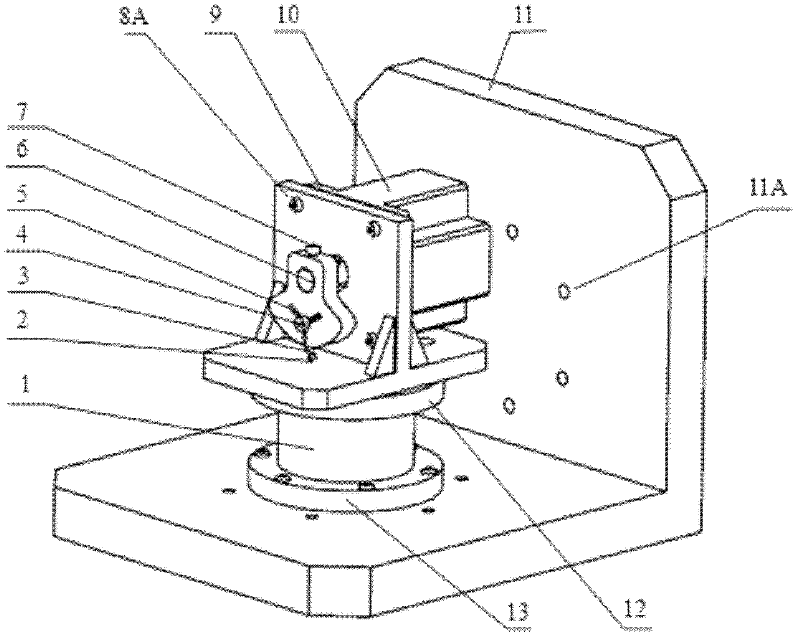

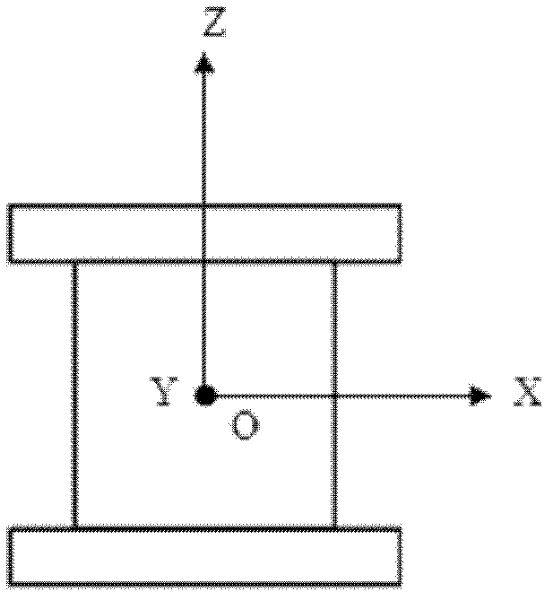

[0086] Before the load cell 1 to be measured is installed, the end surface of the horizontal plate of the base 11 should be calibrated horizontally with equipment such as a spirit level, and then the base 11 should be rigidly fixed to the ground through anchor bolts or pressure plates.

[0087] The rotating motor 10 is fastened and connected by bolts to the vertical plate of the T-shaped stand 8A via the flange, and the output shaft 6 of the rotating motor cooperates with the center of rotation hole 5A of the eccentric excitation block to adjust the center of rotation hole 5A of the eccentric excitation block. After being located directly above the force sensor 1 to be measured, the output shaft 6 of the rotating motor and the eccentric excitation block 5 are fastened together by a key block or a locking screw 7 .

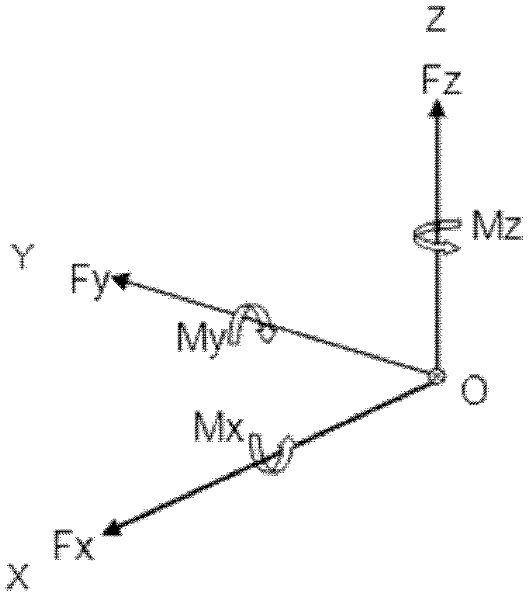

[0088] When the exciting force Fz, the exciting moment My or the exciting moment Mx is loaded, the force sensor 1 to be measured should be placed horizontally on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com