In-situ modeling test system for live loading of high-speed railway

A simulation test system, high-speed railway technology, applied in the direction of electric components, control mechanical energy, electrical components, etc., can solve the problems of not being able to meet the dynamic test of the railway prototype, inconvenient installation and replacement, and large volume of concrete blocks, so as to solve the problem of power transmission and dynamic stability problems, prolong service life, and enhance the effect of rotational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

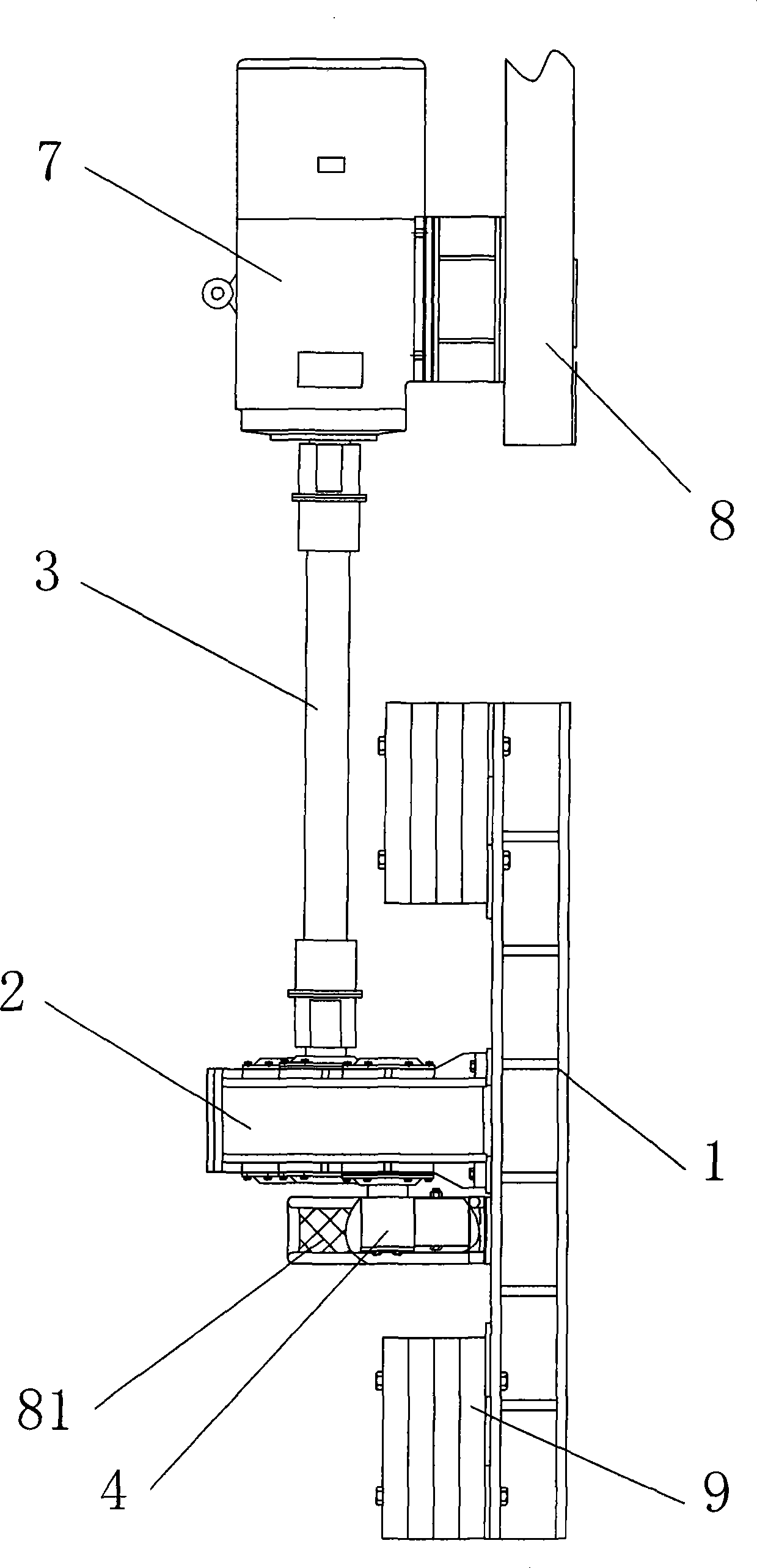

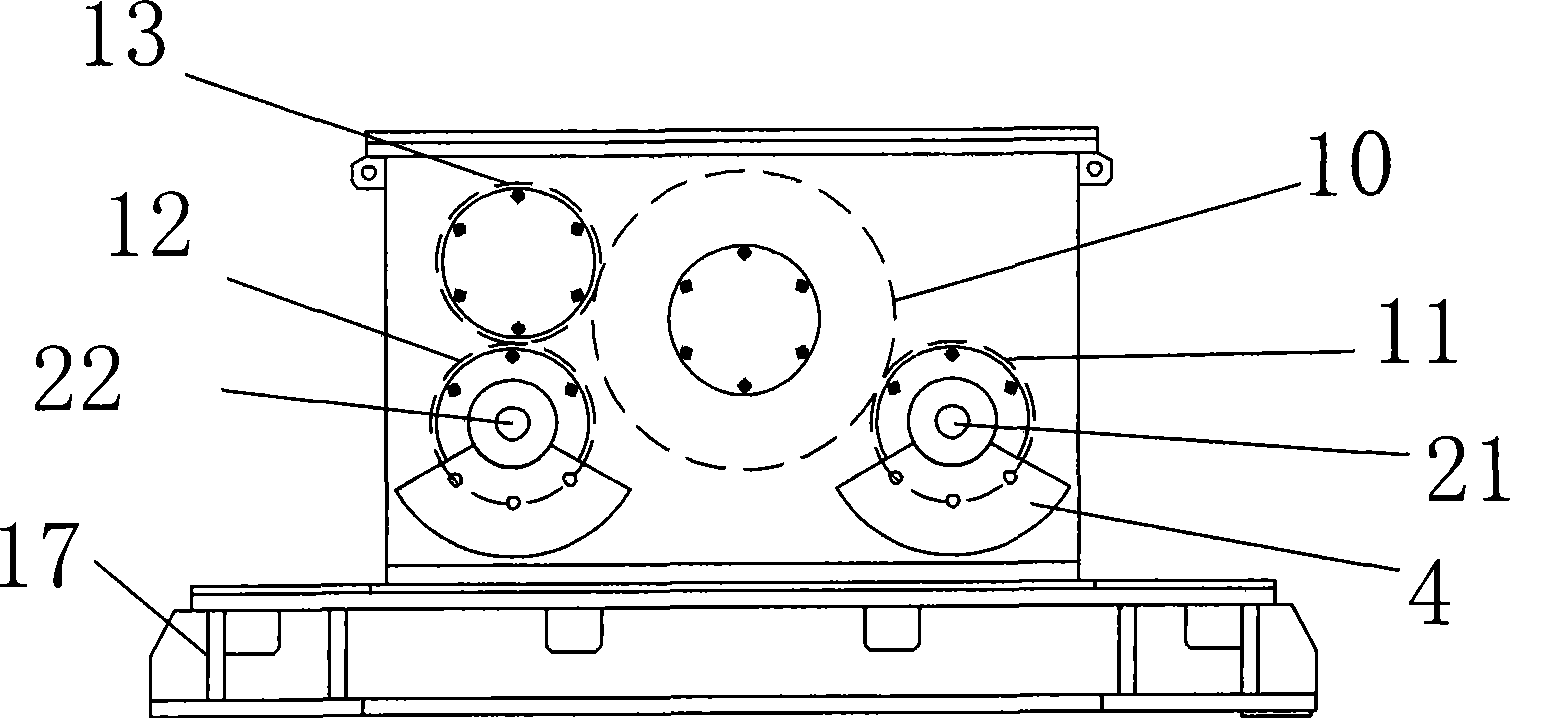

[0025] figure 1 , figure 2 As shown, a specific embodiment of the present invention is: a high-speed railway dynamic load field simulation test system, which is composed of: a motor 7 with variable frequency speed regulation is fixedly installed on a motor installation trolley 8, and the motor 7 shaft passes through the universal The shaft coupling 3 is connected with the input shaft on one side of the speed increaser 2, and the front and rear output shafts 21, 22 of equal height on the other side of the speed increaser 2 are connected with the same eccentric block 4, and the front and rear output shafts 21 The rotating speeds of , 22 are equal, and the direction of rotation is opposite, and the speed increaser 2 is fixed on the center of the vibrating frame 1 upper surface.

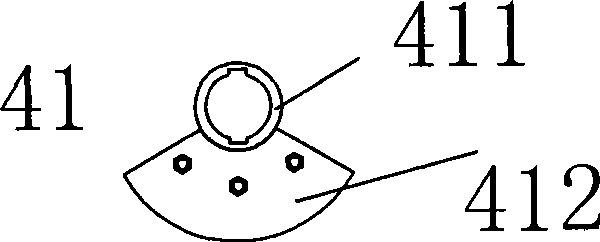

[0026] image 3 , Figure 4 As shown, the eccentric weight 4 is composed of an eccentric weight base 41 and an arc weight 42, wherein the eccentric weight base 41 is composed of an upper key connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com