Table top of vibration platform

A vibrating platform and table top technology, applied in casting and forming equipment, metal processing equipment, molding machines, etc., can solve the problems of large clamping force between the sand box and the table top, the motor and the clamping device are easily damaged, and the table top is worn.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

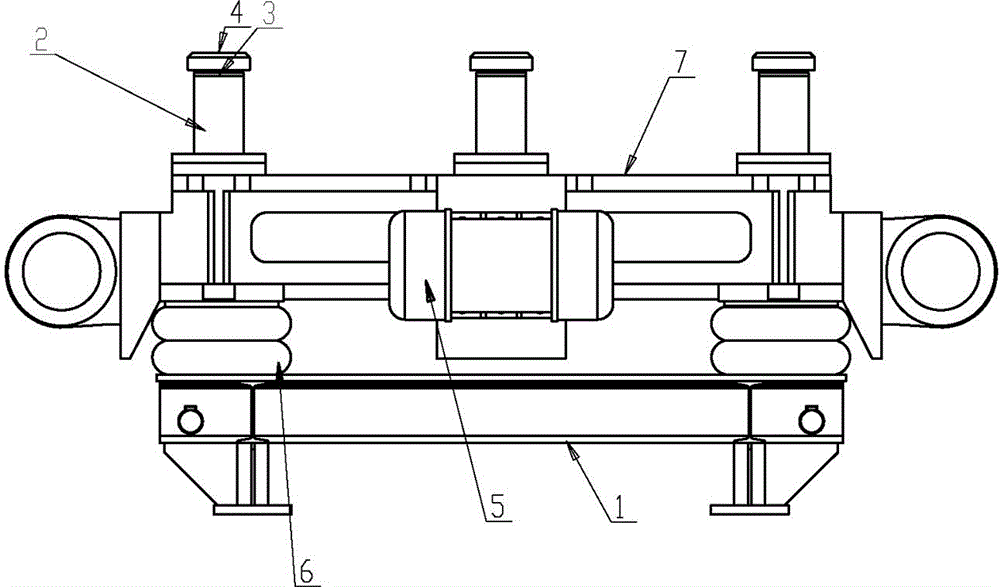

[0010] Depend on figure 1 It can be known that a table top of a vibrating platform includes a platen 7 driven to vibrate by a vibrating mechanism, and three support columns 2 are evenly distributed on the platen 7, and one end of the support column 2 is positioned with the platen 7 by a seam, and is connected by a pair of bolts On the platform 7, the other end of the support column 2 is provided with a connecting seat 3 for installing the sand box, and the contact surface between the connecting seat 3 and the sand box is a convex cone surface.

[0011] In the present invention, the platen 7 with the vibration mechanism is installed on the base 1 through 8 to 12 (8 in this embodiment) airbags 6, and the lift of the console plate 7 can be controlled by filling and releasing compressed air in the airbags 6. ,drop. The bottom of the sand box is welded wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com