Secondary variable pendulum chaotic vibrating mill

A vibrating mill and pendulum technology, applied in the direction of fluid and grain processing using vibration, can solve the problems of system loss of stability, anti-grinding, non-refinement, etc., to improve rapidity and reliability, reduce starting torque, The effect of preventing resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

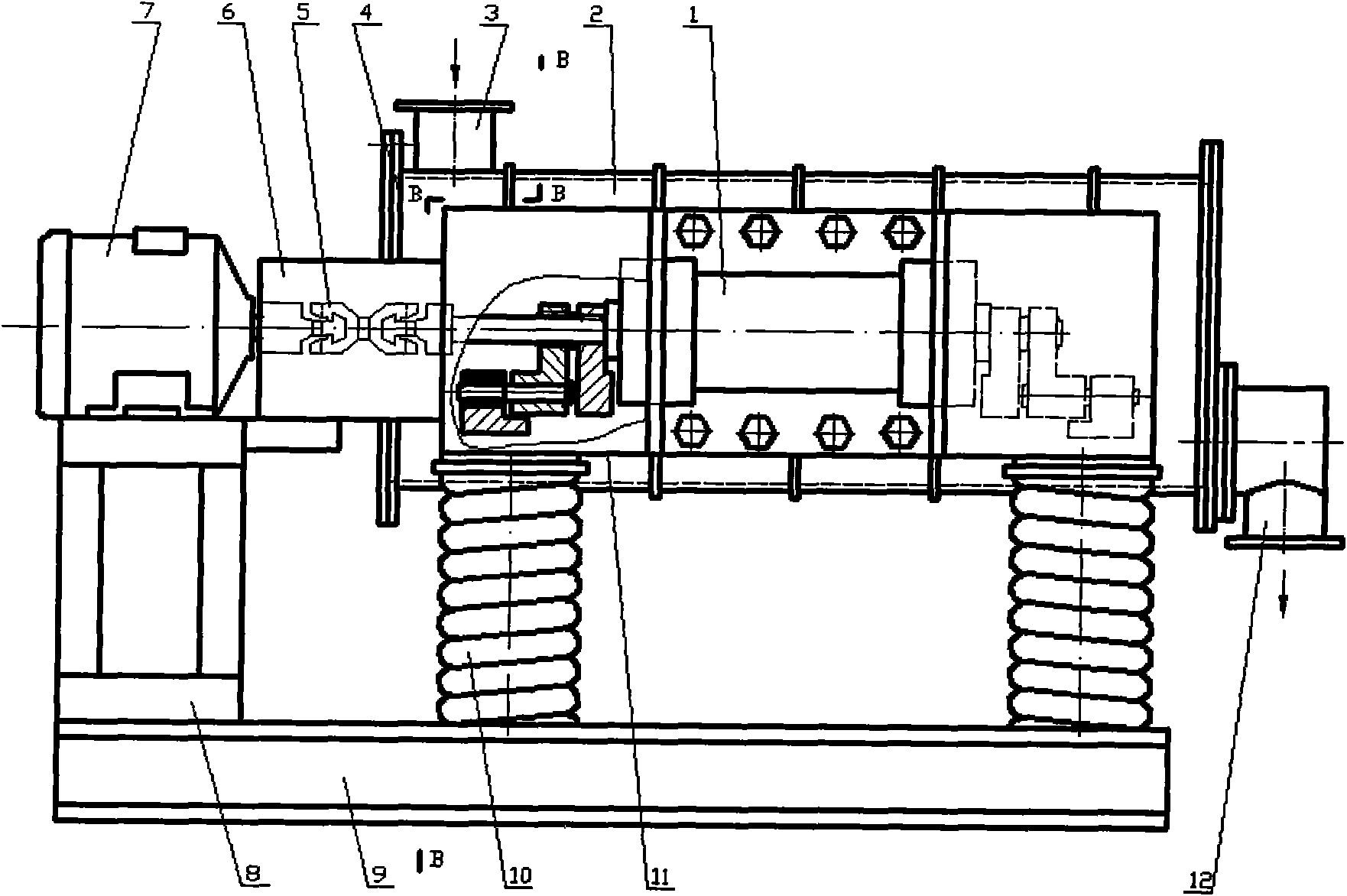

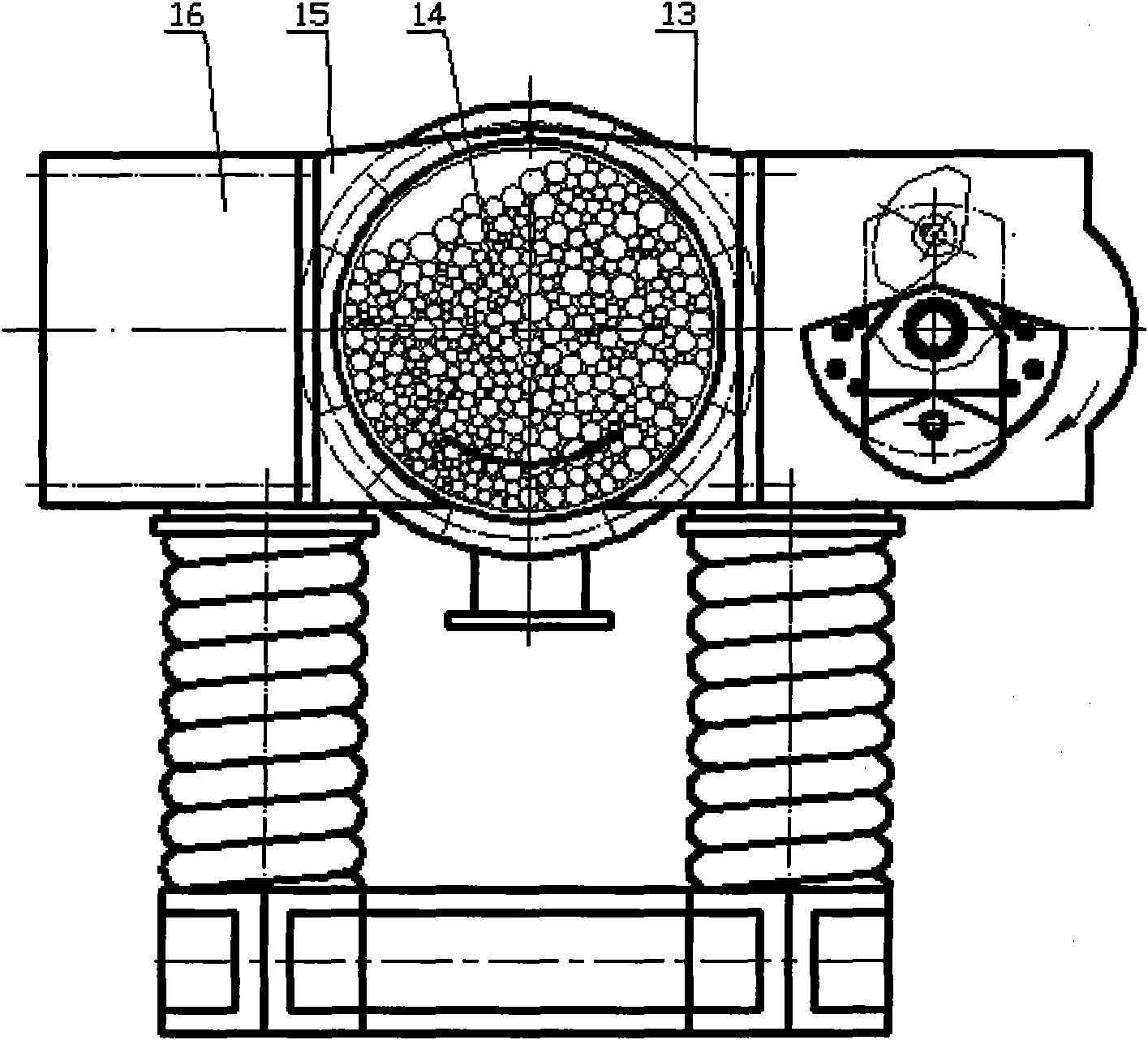

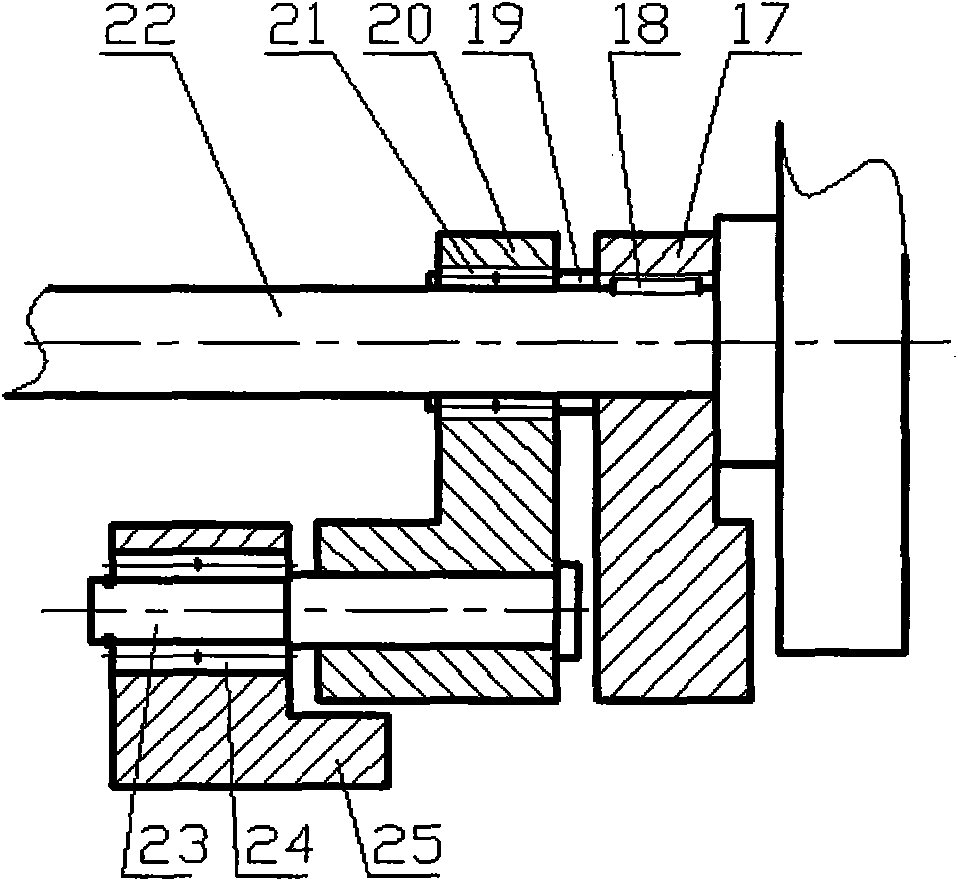

[0034] attached Figure 1-2 It is an embodiment of the present invention in the form of a single body structure, with Figure 1-2The secondary swinging chaotic vibrating mill includes vibrator 1, cylinder body 2, feed port 3, end cover 4, coupling 5, coupling cover 6, motor 7, motor base 8, base 9, screw Spring 10, swing cover 11, discharge port 12, right coupling frame 13, grinding medium 14, left coupling frame 15, counterweight body 16.

[0035] Refer to attached figure 1 , The vibration mass body of the present invention includes a vibrator 1, a cylinder body 2, a grinding medium 14, a counterweight body 16, and the like. In this embodiment, there is a cylinder, and the vibrator 1 is rigidly fixed on the right side of the cylinder 2 as the excitation source, and the cylinder 2 is excited on one side in a biased manner, that is, the axis of gravity and the center of gravity of the cylinder 2 In addition to its excitation, a counterweight 16 is set to balance the quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com