Cement clinker grinding implementation equipment and stirring device thereof

A technology of cement clinker and mixing device, which is used in transportation and packaging, dissolving, grain processing, etc., to reduce energy consumption, eliminate dead material areas, and increase production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

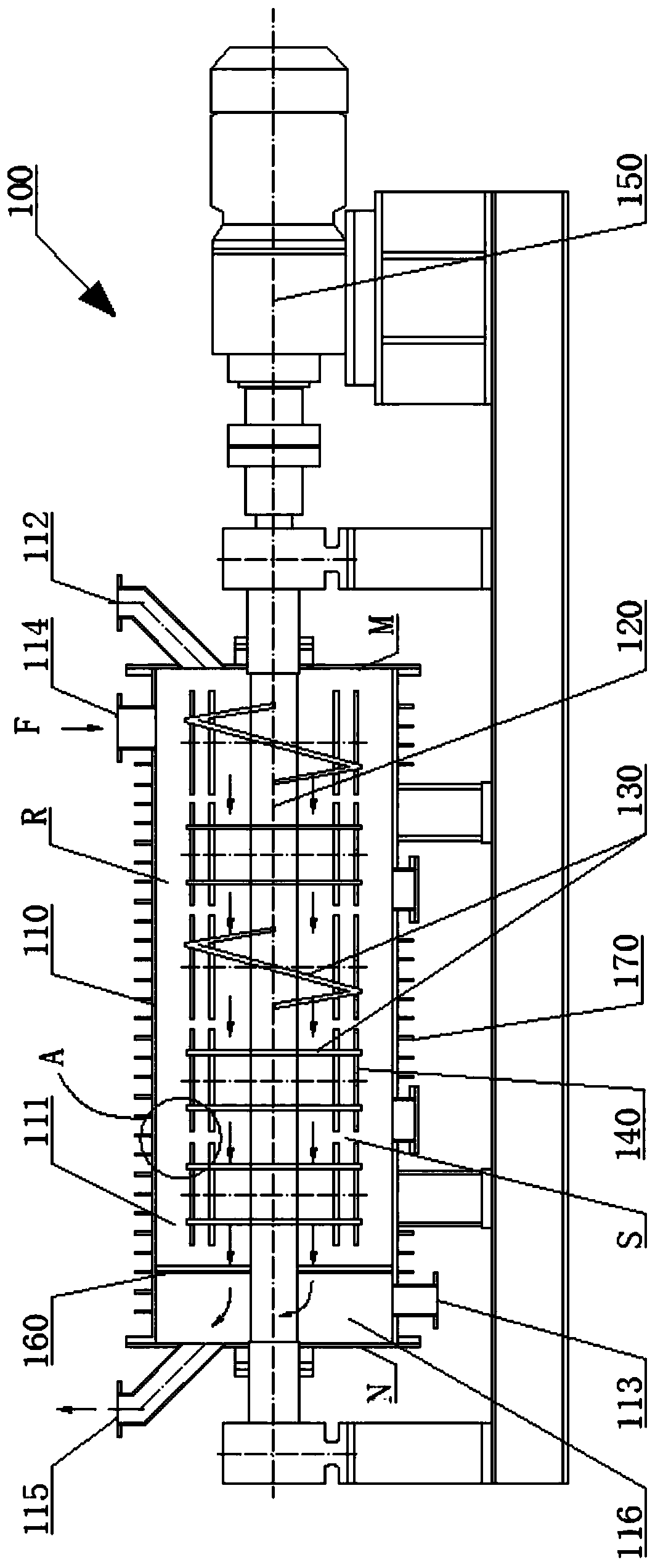

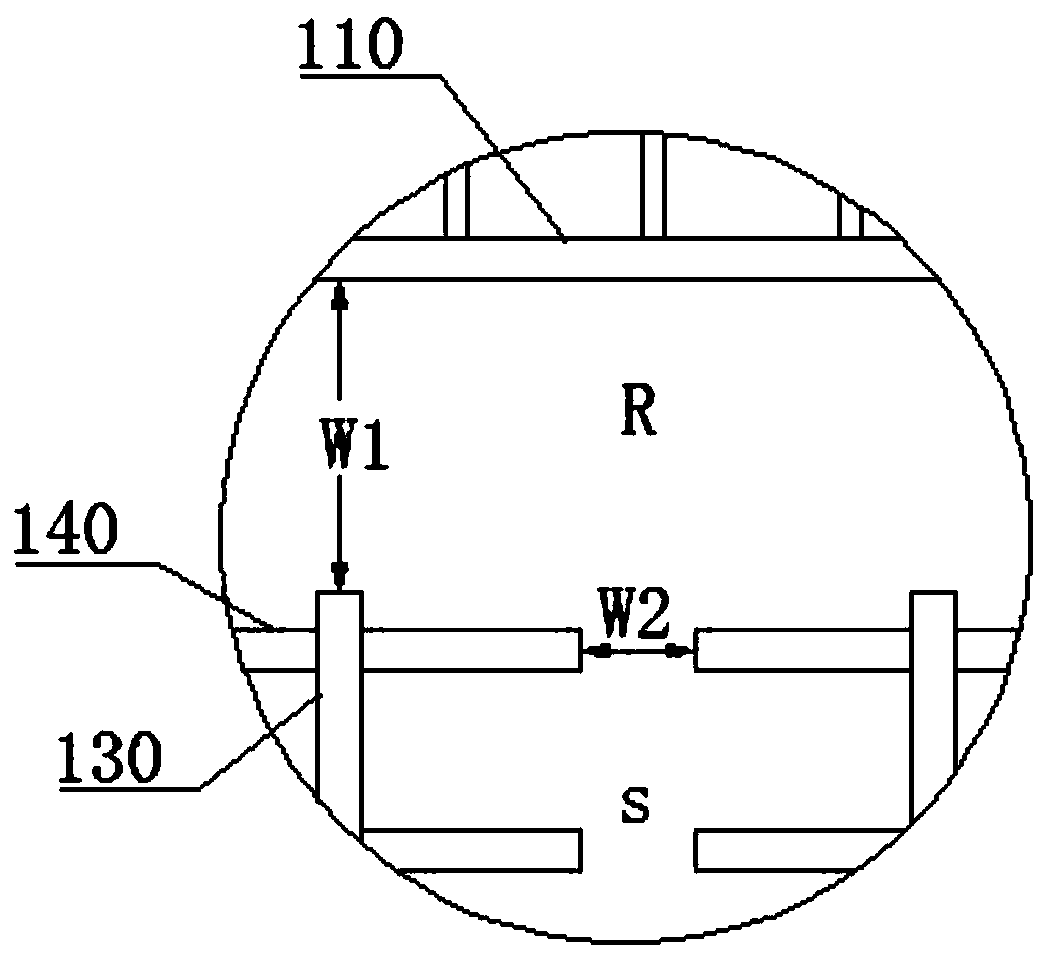

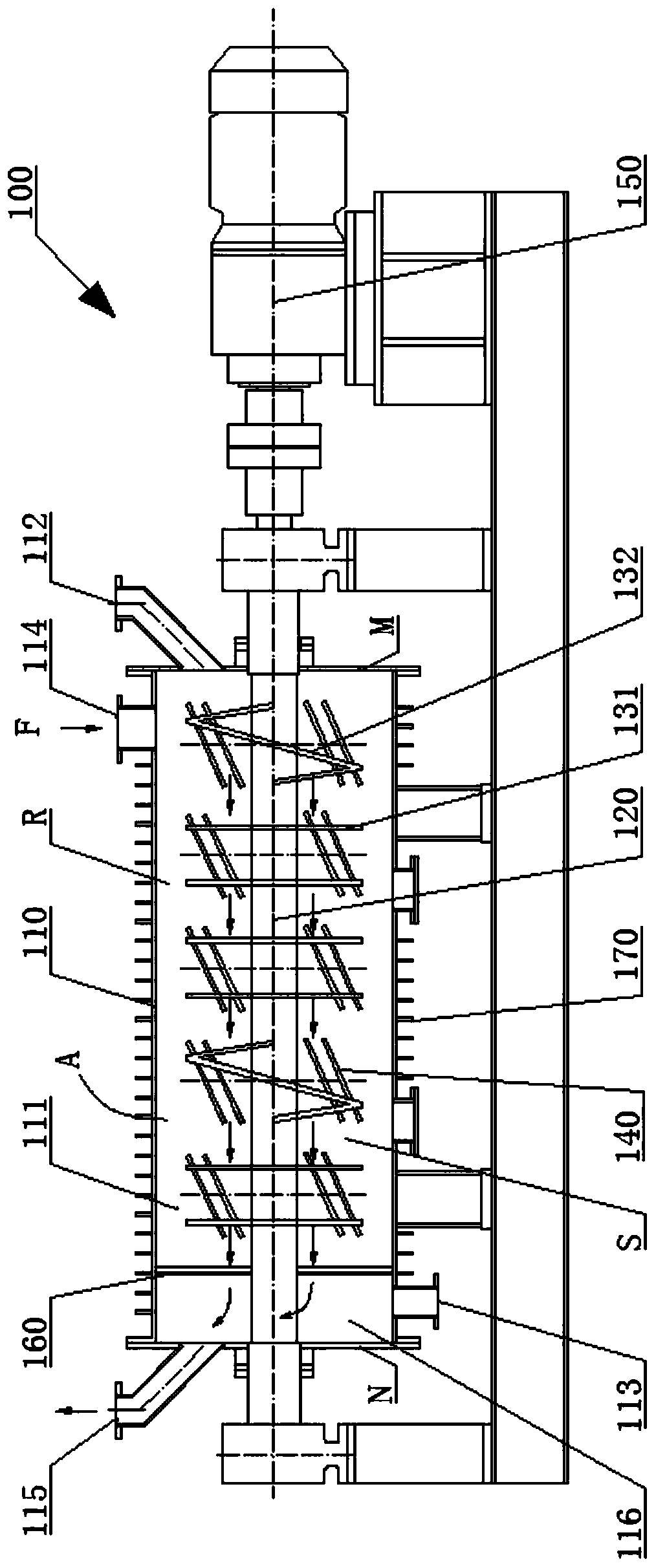

[0043] refer to figure 1 Illustrate the stirring device according to the cement clinker grinding implementation equipment 100 disclosed in this embodiment, which includes a stirring shaft 120, a stirring unit 130 and a reinforcing stirring member 140, the stirring unit 130 is installed on the stirring shaft 120, the stirring unit 130 and the stirring shaft 120 is preferably connected by keys or bolts, and the reinforcing stirring member 140 is installed on the stirring unit 130, and the number of the stirring unit 130 and the reinforcing stirring member 140 is at least one. When the number of stirring units 130 is greater than 1, the stirring units 130 are arranged in sequence along the axial direction of the stirring shaft 120 .

[0044] When the stirring shaft 120 rotates, the stirring unit 130 rotates together with the stirring shaft 120 . The stirring unit 130 protrudes from the stirring shaft 120 radially along the stirring shaft 120 and is the main functional element of...

Embodiment 2

[0052] refer to figure 1 Explain that the cement clinker grinding implementation equipment 100 disclosed in this embodiment includes a housing 110, a screening device 160 and a stirring device, including a stirring shaft 120 that can be driven to rotate by a drive system 150, and a shaft that is arranged on the stirring shaft 120 Upward at least one stirring unit 130, the two sides of the stirring unit 130 along the axial direction of the stirring shaft 120 form a sub-grinding area S, at least one strengthening stirring piece 140 is connected to the stirring unit 130, and the strengthening stirring piece 140 is in the sub-grinding area S Extending in the grinding zone S, the reinforcing stirring member 140 cooperates with the stirring unit 130 to make at least part of the grinding media and materials in the sub-grinding zone S perform grinding motion along the circumference of the stirring shaft 120 . The housing 110 includes a wall defining a horizontally extending stirring c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com