Manufacturing method of directional drawing magnetic slot wedge

A technology of magnetic slot wedges and manufacturing methods, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as torque reduction, voltage adjustment efficiency reduction, motor starting torque, maximum torque reduction, etc., to achieve Effects of reducing inter-tooth leakage flux, suppressing tooth harmonics, and improving motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

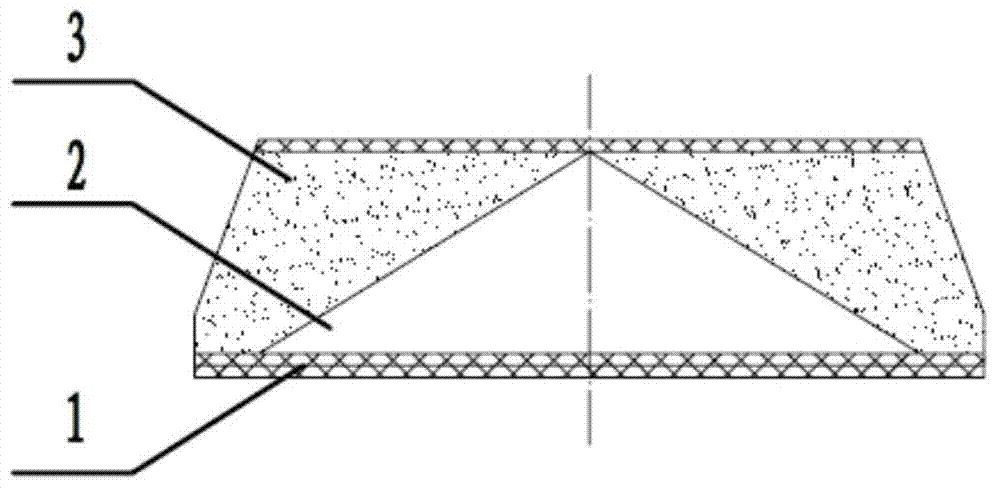

[0015] Such as figure 1 , a manufacturing method for directional drawing magnetic slot wedges, including a rectangular box-shaped mold, two baffles are arranged in the mold to divide the interior of the mold into three areas, and one end of the two baffles is jointly fixed on one side of the mould. The middle part and the other end are against the other side of the mold, so that the area between them is in the shape of an isosceles triangle; the magnetic slot wedge is made of heat-resistant H-class epoxy adhesive, soft magnetic material, and reinforcing material. ; The specific method steps are as follows:

[0016] Mix 9% Al, 5% Si, and 85% Fe powder with coupling agent and stir thoroughly, then add it to the epoxy adhesive and stir evenly, and the alkali-free glass filaments pass through the magnetic epoxy adhesive groove and mold, and are initially drawn into a figure 1 No. 3 rough surface shape, and then reinforced with non-alkali glass ribbon No. 1 of ET80-20, no.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com