Alternating current generator having a plurality of independent three-phase windings

a technology of alternating current generator and three-phase winding, which is applied in the direction of windings, magnetic circuit rotating parts, magnetic circuit shape/form/construction, etc., can solve the problem of reducing the effective magnetic flux, and achieve the effect of reducing the noise of electromagnetic waves, increasing the cost and the size of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

the present invention will be described with reference to FIGS. 11 to 13.

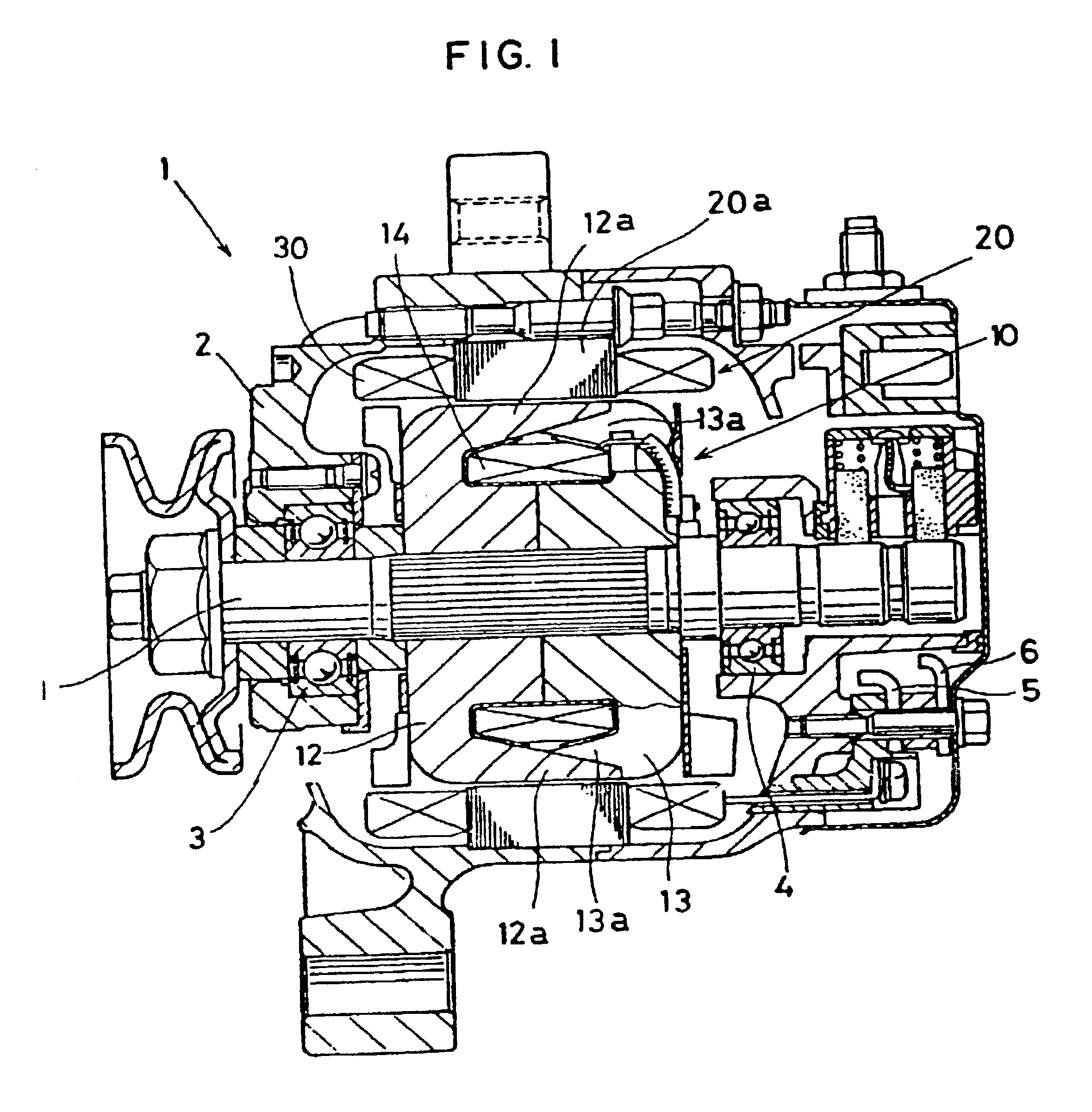

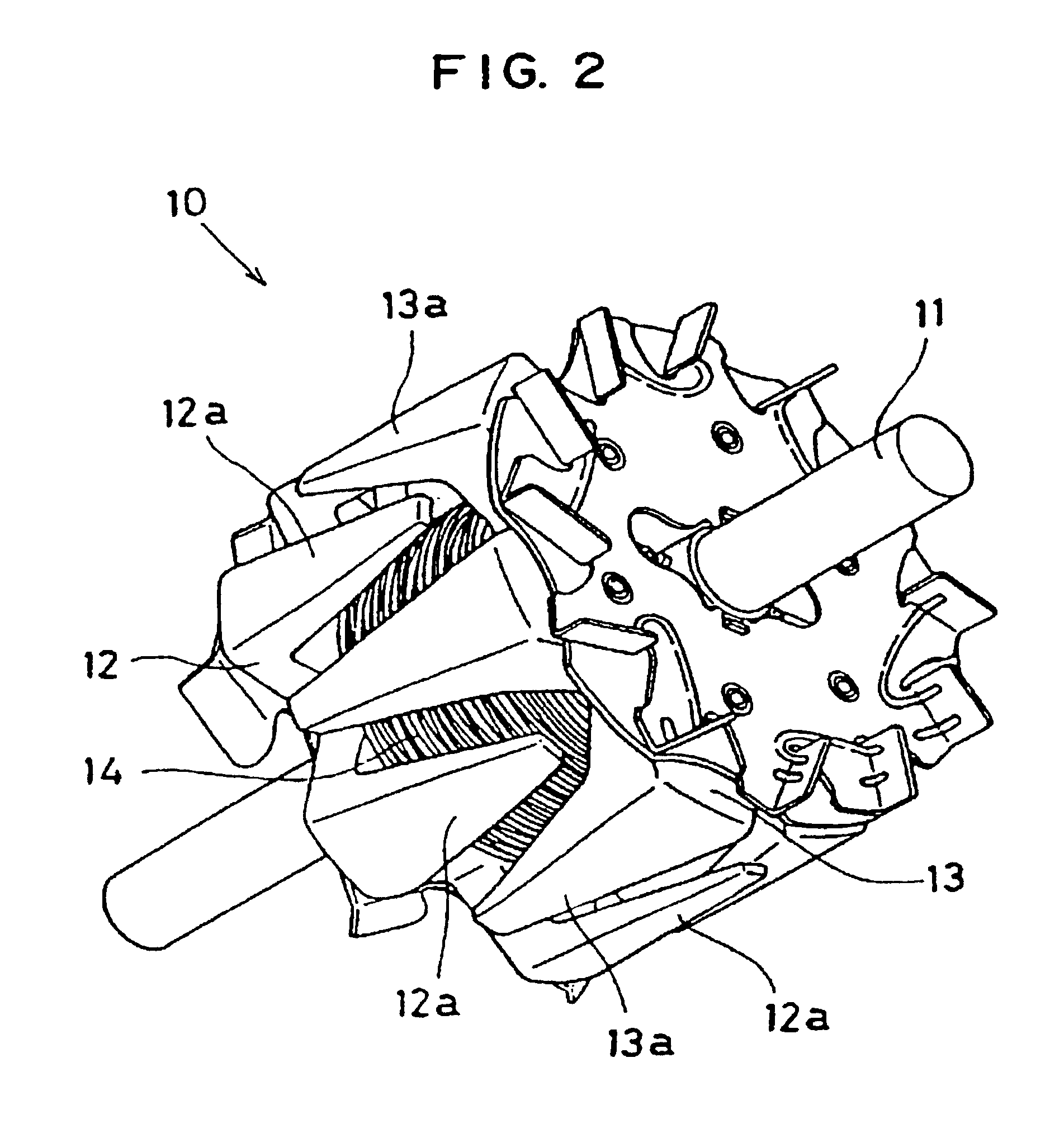

An a.c. generator is generally provided with a cooling fan radially inside of the coil ends of the armature windings projecting on both sides of the armature core (that is, radially inside of the portions of the three-phase armature windings projecting from slots of the armature core) so that the coil ends are forcibly cooled by an air flow produced by the fan.

However, the space between the fan and the coil ends is considerably narrow, so that the action caused by the air flow pressure generated by the fan upon the narrow space is apt to give rise to a fan noise. In particular, since the coil ends of the armature windings have a concave and convex shape having a predetermined pitch, a noise having a given audio frequency is generated.

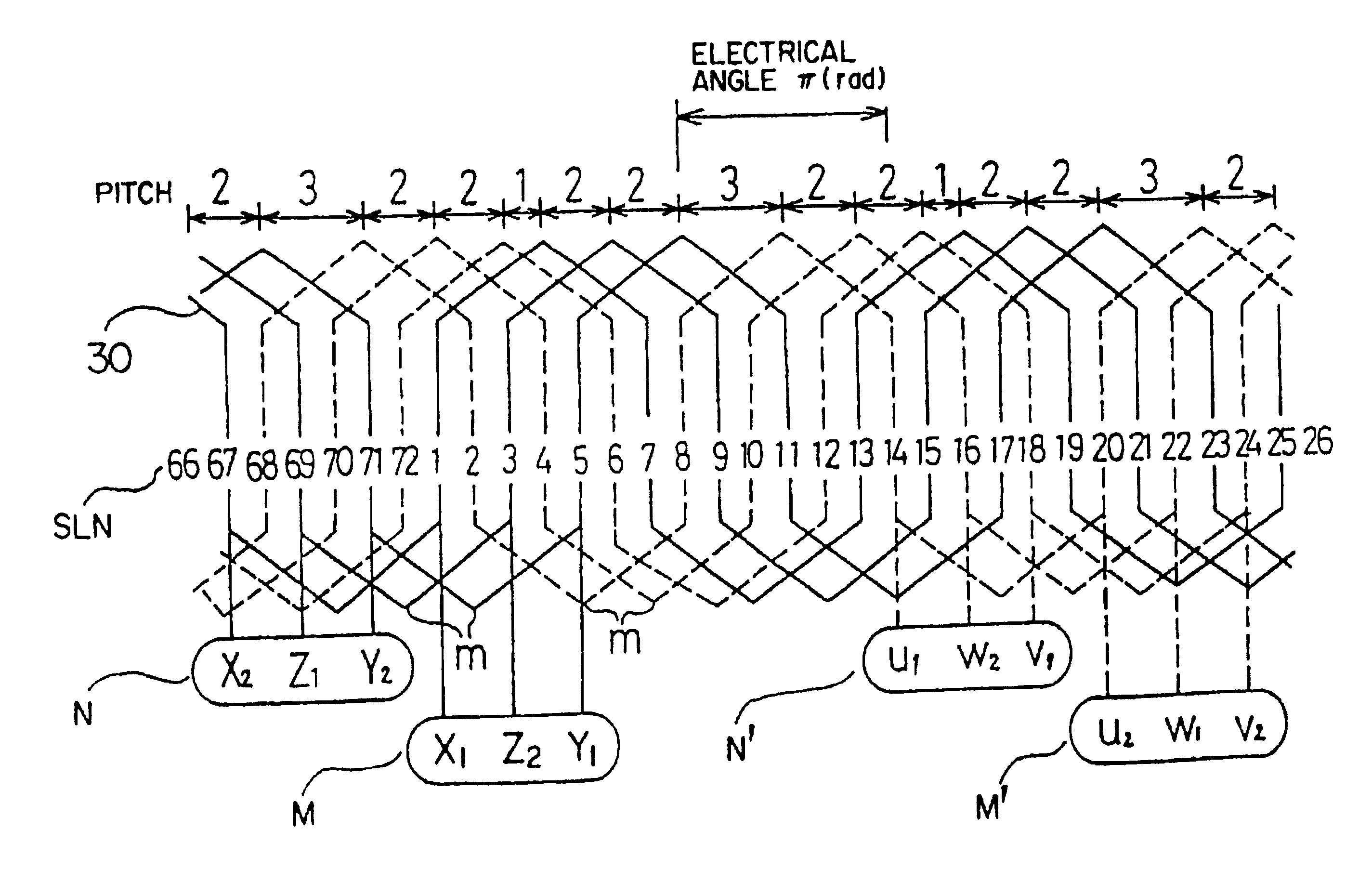

It is desired in such a three-phase a.c. generator to prevent excessive congregation of coil ends as far as possible and to make constant the density of the arrangement of the coil...

fourth embodiment

the present invention will now be described.

Generally, there have been a three-phase a.c. generators having three-phase armature windings which are connected in Y-form or delta-form and which are wound concentratedly with full pitch on an armature core having three slots per one-pole pitch. With such a type of three-phase a.c. generator, even if a phase current flowing through each phase armature winding X, Y and Z is sinusoidal, the distribution of the air gap magnetomotive force remarkably fluctuates along the circumference of the rotor due to an influence of the third harmonic current contained in the armature current. Accordingly, the distribution of the air gap magnetomotive force is greatly distorted with the movement of a rotor in a rotational direction thereof, and, at the same time, the distribution of the air gap magnetomotive force fluctuates relative to the magnetic poles of the rotor. Therefore, there has been raised a problem that a noise is generated by the magnetic i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com