Alternating drive, primarily for bicycles and similar driven vehicles

An alternately driven, driven technology that can be used in vehicle components, rider drive, transportation and packaging to solve problems such as difficulty in changing gear ratios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

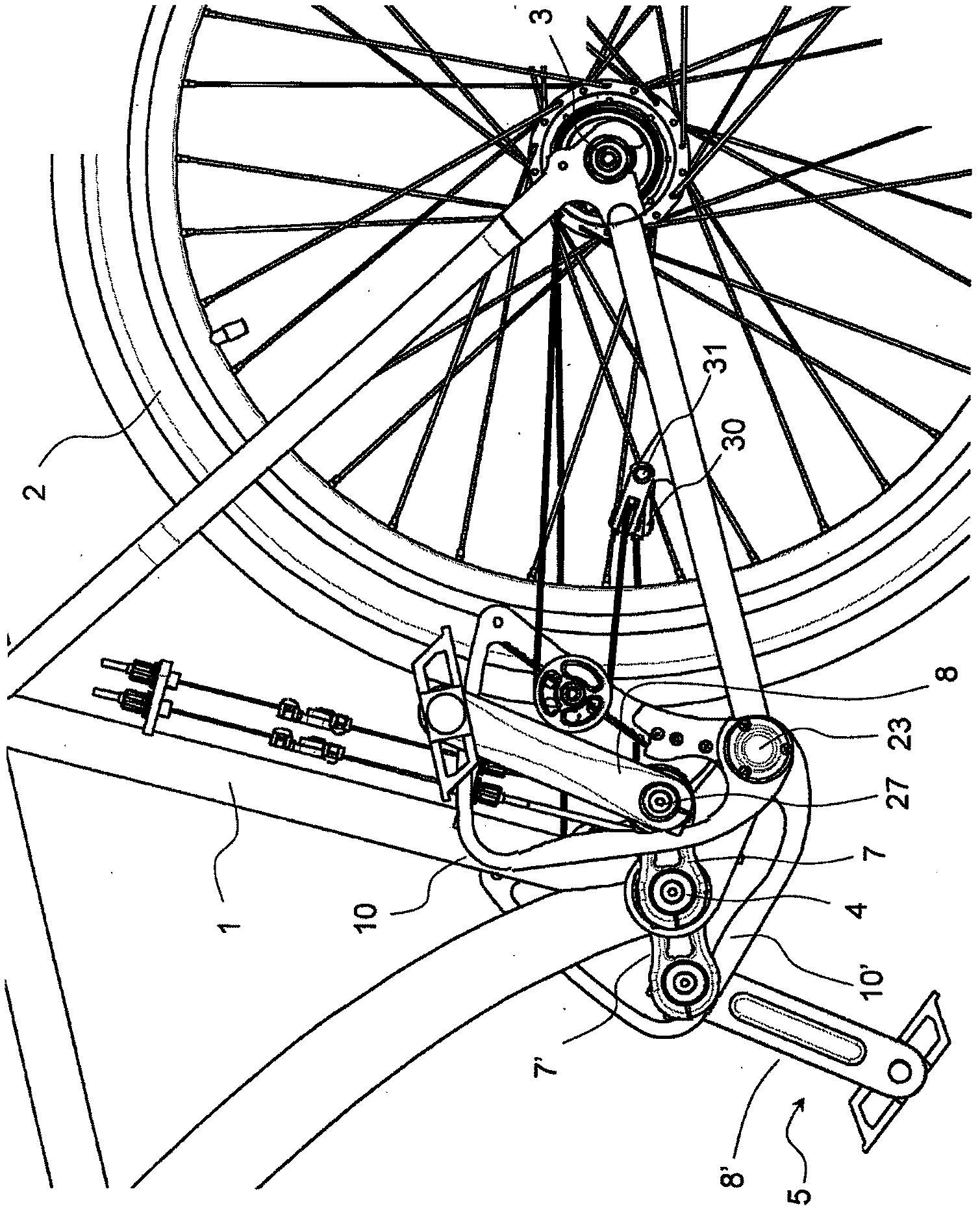

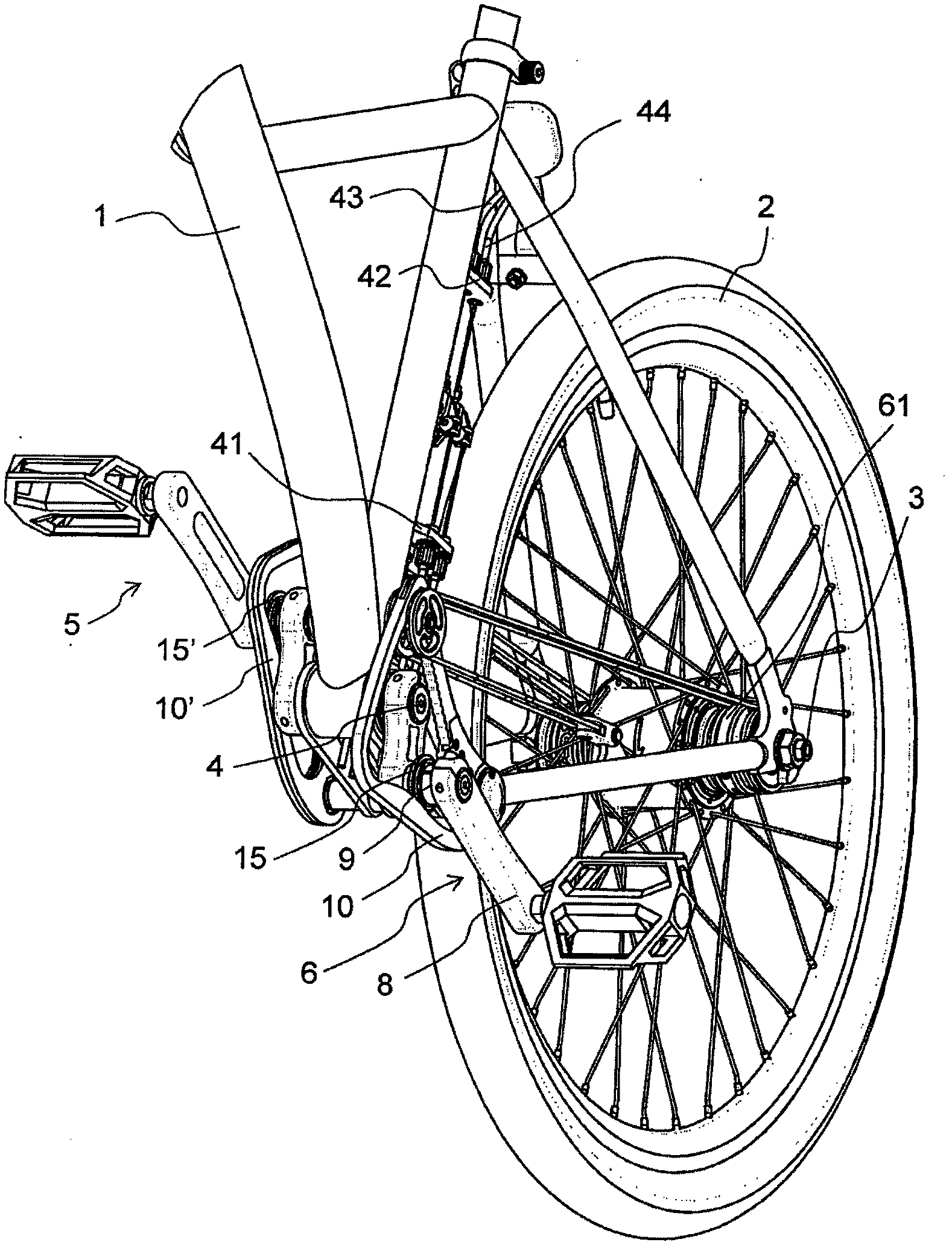

[0031] figure 1 and 2 A perspective view showing a detail of a bicycle with a drive device according to the invention using a swing arm from a different perspective. In addition to the drive system used, the bicycle is also equipped with conventional parts or units, including a rigid frame 1 made of tubular elements, with corresponding front and rear wheel holding forks, and in the rear fork The end area is provided with a corresponding groove or socket for mounting the end of the axle 3 of the rear wheel 2 . The front fork and front wheel are not shown in the figure because the front wheel is not driven.

[0032]The frame 1 has frame rods which extend and branch from below approximately in a V-shape towards the handlebar and the saddle respectively, and these rods are connected to each other at their lower ends, and a lower hollow connection is provided in this connection region element, which has a different design compared to a similar connection area on a conventional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com