Harmonic reducer and mechanical arm

A technology of harmonic reducer and manipulator, applied in mechanical equipment, transmission parts, belt/chain/gear, etc., can solve problems such as heat generation, unstable operation, and increased energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

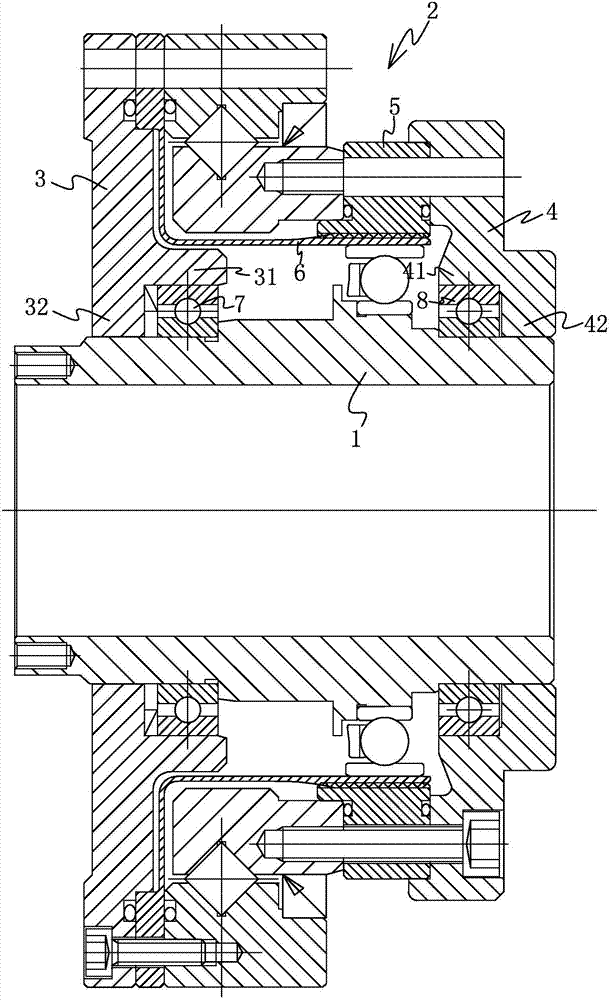

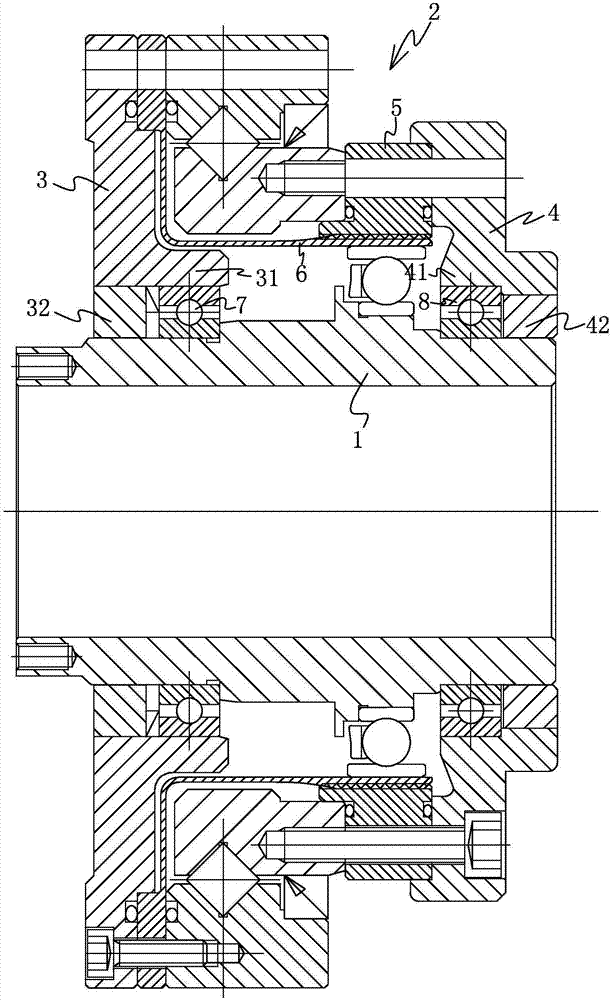

[0027] Such as figure 1 As shown, the harmonic reducer includes a hollow inner shaft 1 and a casing 2 located outside the inner shaft 1 . Among them, the inner shaft 1 is used as the input end of the wave generator in the reducer. When the harmonic reducer is in operation, the inner shaft 1 rotates relative to the outer shell 2 inside the outer shell 2 .

[0028] The casing 2 includes end caps one 3 and two end caps 4 , both of which are ring-shaped and sleeved on the inner shaft 1 . There is a cavity between the end cover one 3 and the end cover two 4 for setting the steel wheel 5 and the flexible wheel 6, that is to say, the steel wheel 5 and the flexible wheel 6 are located inside the end cover one 3 and the end cover two 4 . Lubricating grease is filled between the end cap one 3 and the end cap two 4 .

[0029] Wherein, the end cover one 3 has a part one 31 and a part two 32, a bearing one 7 is arranged between the part one 31 and the inner shaft 1, and a gap seal is f...

Embodiment 2

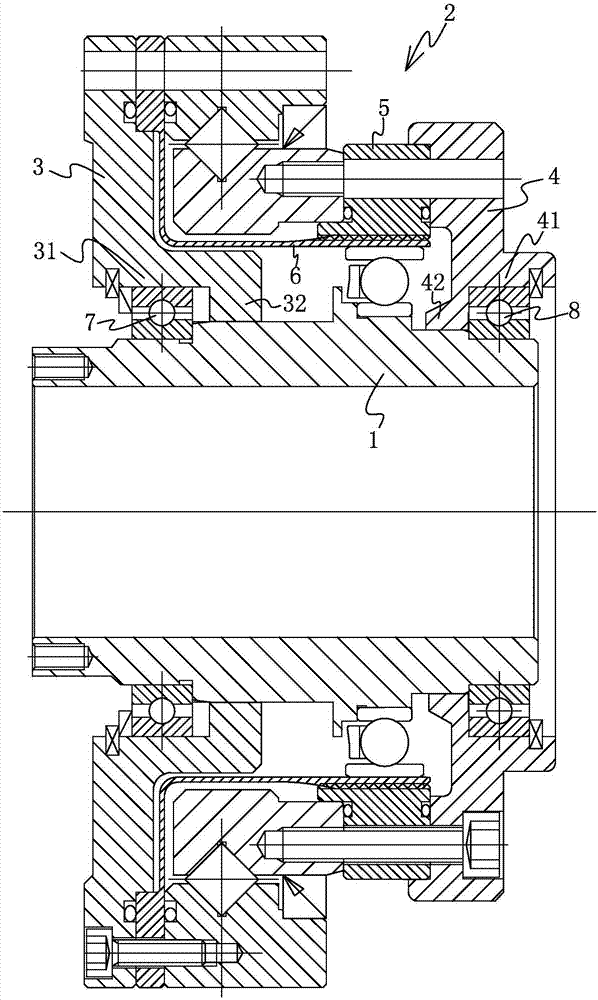

[0035] This embodiment is substantially the same as Embodiment 1, the difference is that in this embodiment, if figure 2 As shown, on the end cover 3, the part 2 32 is located inside the part 1 31; on the end cover 2 4, the part 4 42 is located inside the part 3 41. Such a structure, on the one hand, makes the cavity between the first end cover 3 and the second end cover 4 smaller, reducing the use of lubricating substances, and on the other hand, makes the structure of the harmonic reducer more compact.

[0036] According to the purpose of the present invention, the present invention also proposes a kind of manipulator that runs smoothly, and its technical scheme is as follows:

[0037] Manipulator, including the above-mentioned harmonic reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com