Series connection type high energy electromagnetic actuator

An electromagnetic actuator, series-connected technology, applied in the field of machinery, can solve the problems of large amount of high-strength magnets, high material cost, small excitation force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

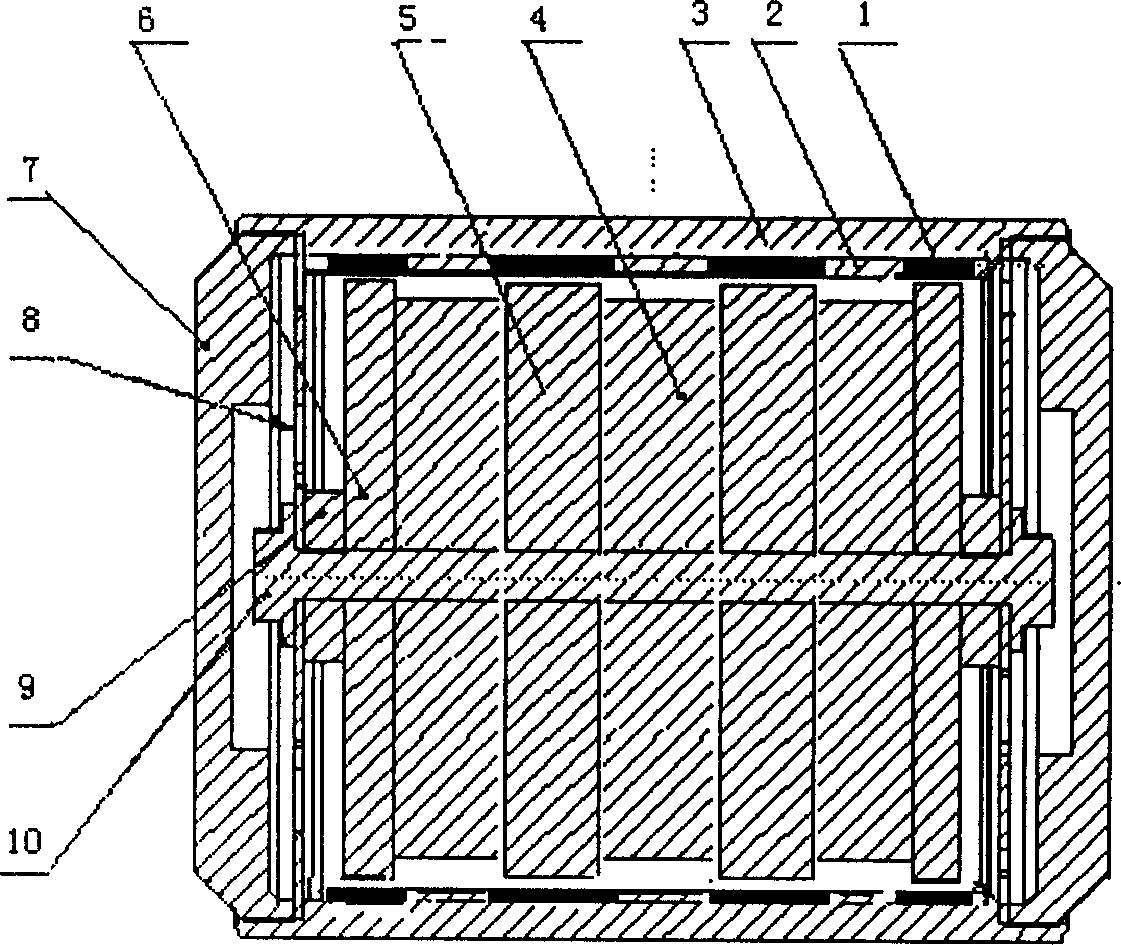

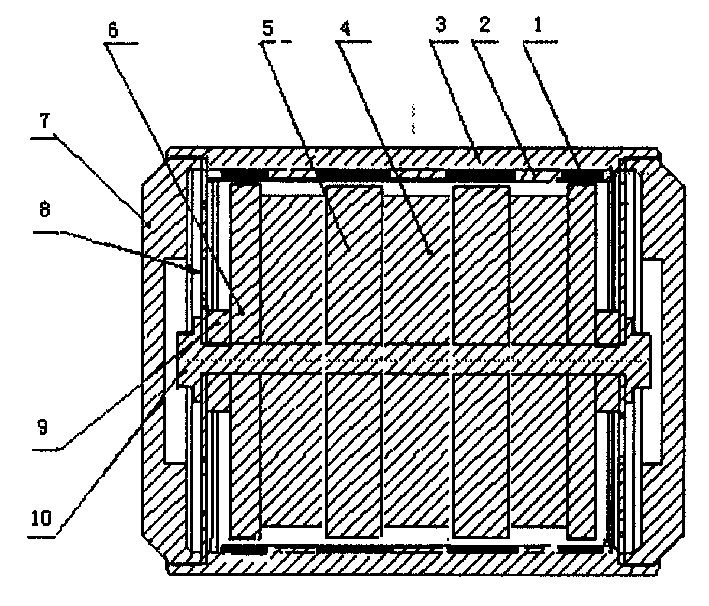

[0009] exist figure 1 Among them, three high-strength magnets (4), two middle magnetic conductive plates (5) and two outer magnetic conductive plates (6) are connected in series at intervals to form a vibrator. The thickness of the middle magnetic conduction plate (5) is greater than the thickness of the outer magnetic conduction plate (6), and two adjacent high-strength magnets (4) are adsorbed on both sides of the middle magnetic conduction plate (5) oppositely with the same pole. There are coil slots on the coil holder (2) corresponding to the middle magnetic plate (5) and the outer magnetic plate (6), and the built-in electromagnetic coil (1), the winding direction or wiring design of the electromagnetic coil (1) The current directions of any two adjacent electromagnetic coils (1) must be opposite. The coil holder (2), the electromagnetic coil (1) and the magnetically permeable outer cylinder (3) are cemented into a whole. The leaf spring (8), the through-bolt (10) and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com