Motor-driven non-contact shock excitation device and shock excitation method thereof

A motor-driven and vibration-exciting device technology, which is used in measuring devices, machine/structural component testing, vibration testing, etc. The effect of axial excitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

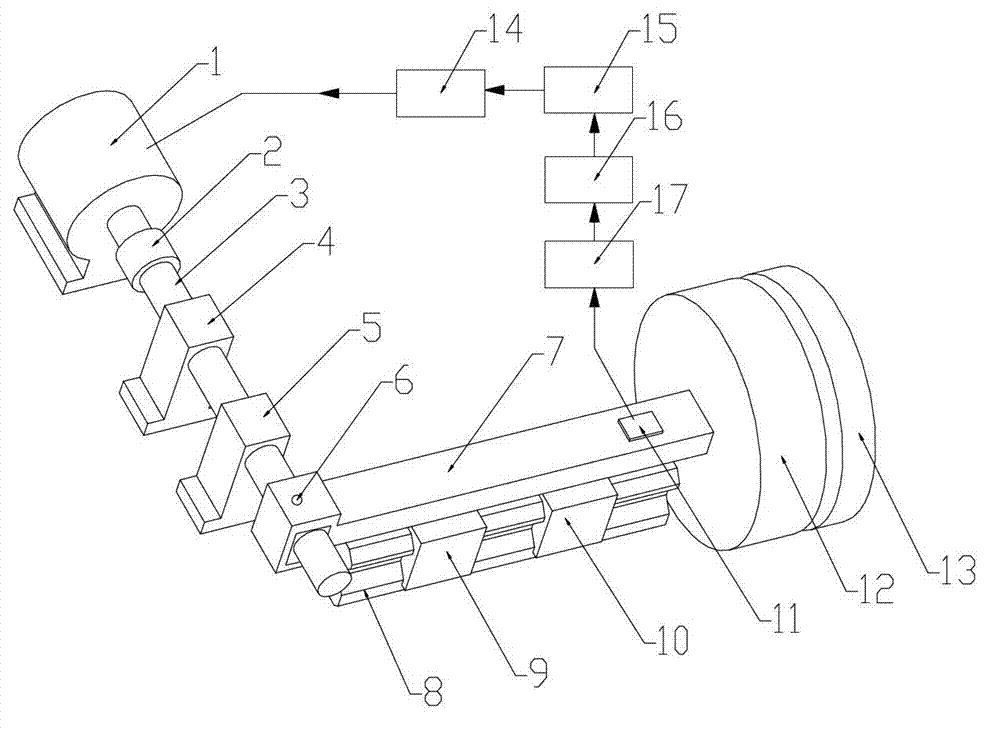

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

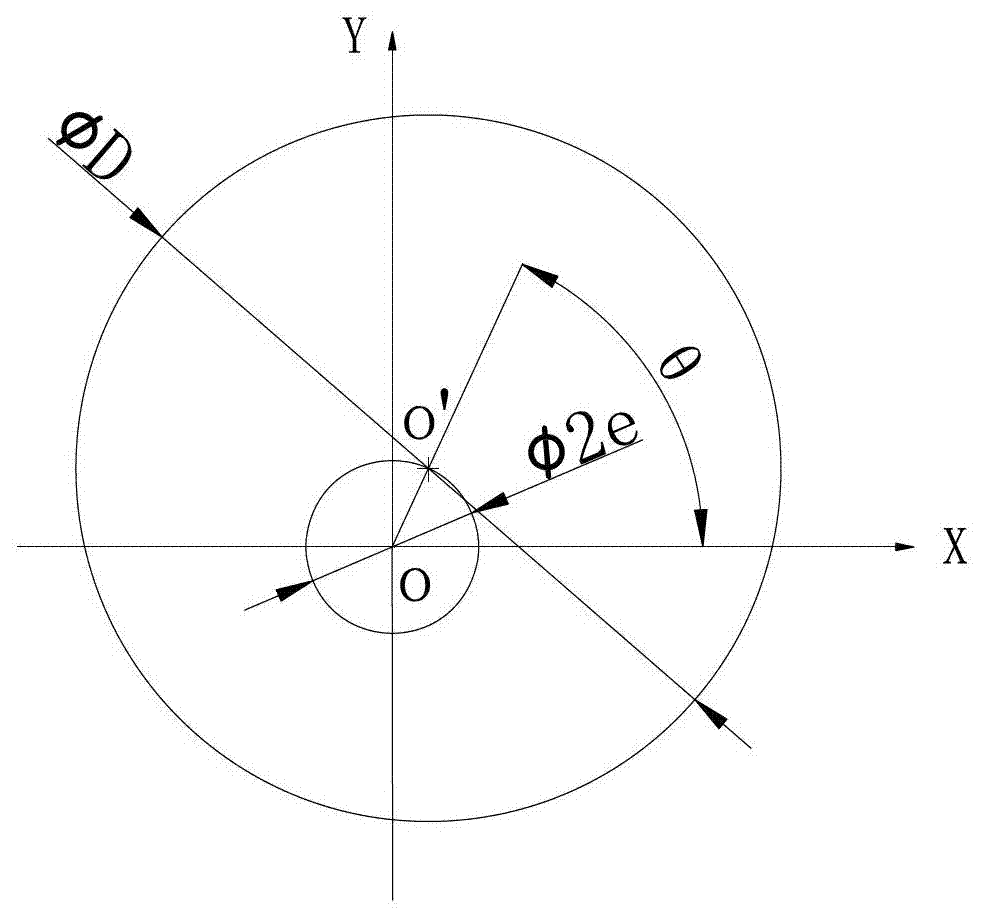

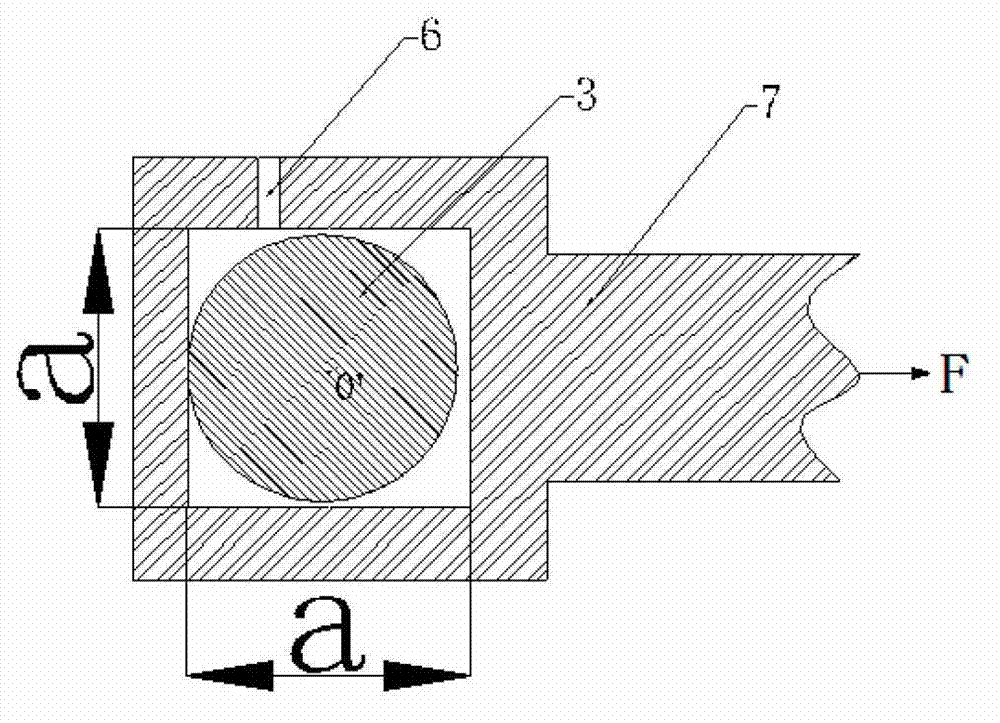

[0031] see Figure 1 to Figure 4 As shown, a motor-driven non-contact excitation device of the present invention includes a stepping motor 1, a shaft coupling 2, an eccentric shaft 3, a first support bearing 4, a second support bearing 5, a connecting rod 7, and a linear guide rail 8 , the first slider 9, the second slider 10, the electro-permanent magnet 12, the armature 13, the strain gauge bridge 11, the strain signal conditioning circuit 17, the AD converter 16, the industrial computer 15 and the subdivision driver 14. The subdivision driver 14 drives the stepping motor 1, and the stepping motor 1 drives the eccentric shaft 3 through the shaft coupling 2, and the first supporting bearing 4 and the second supporting bearing 5 arranged at intervals are used to support the eccentric shaft 3. The first slider 9 and the second slider 10 are fixed on the linear guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com