Mechanical vibration exciter and torsion test vibration excitation equipment adopting same

A vibration exciter, mechanical technology, applied in the direction of fluid using vibration, etc., can solve the problems of inaccurate test results, inconvenient installation, failure to meet the test requirements, etc., to achieve high accuracy of test results and convenient installation and use , the effect of meeting the test requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

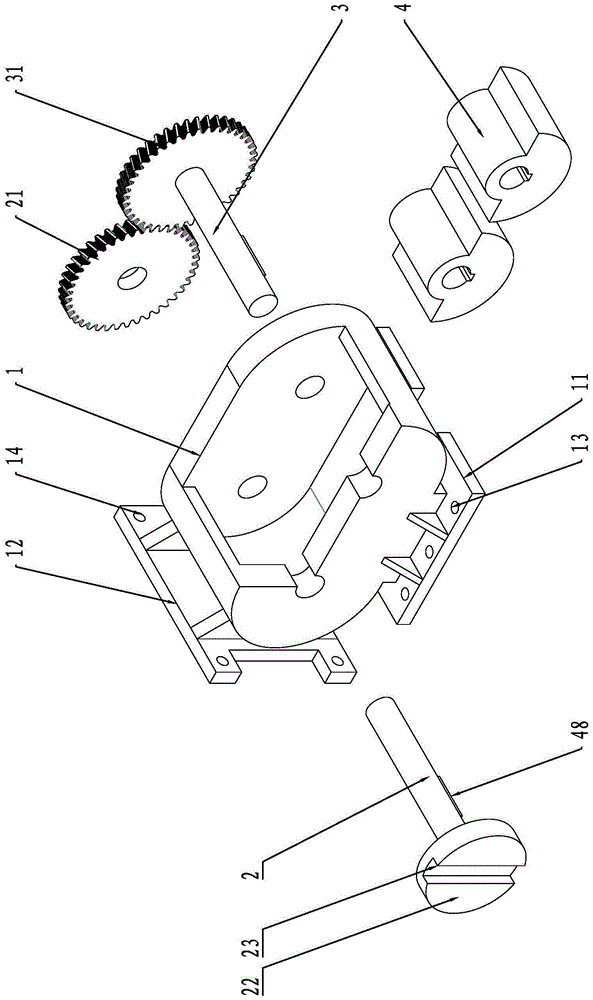

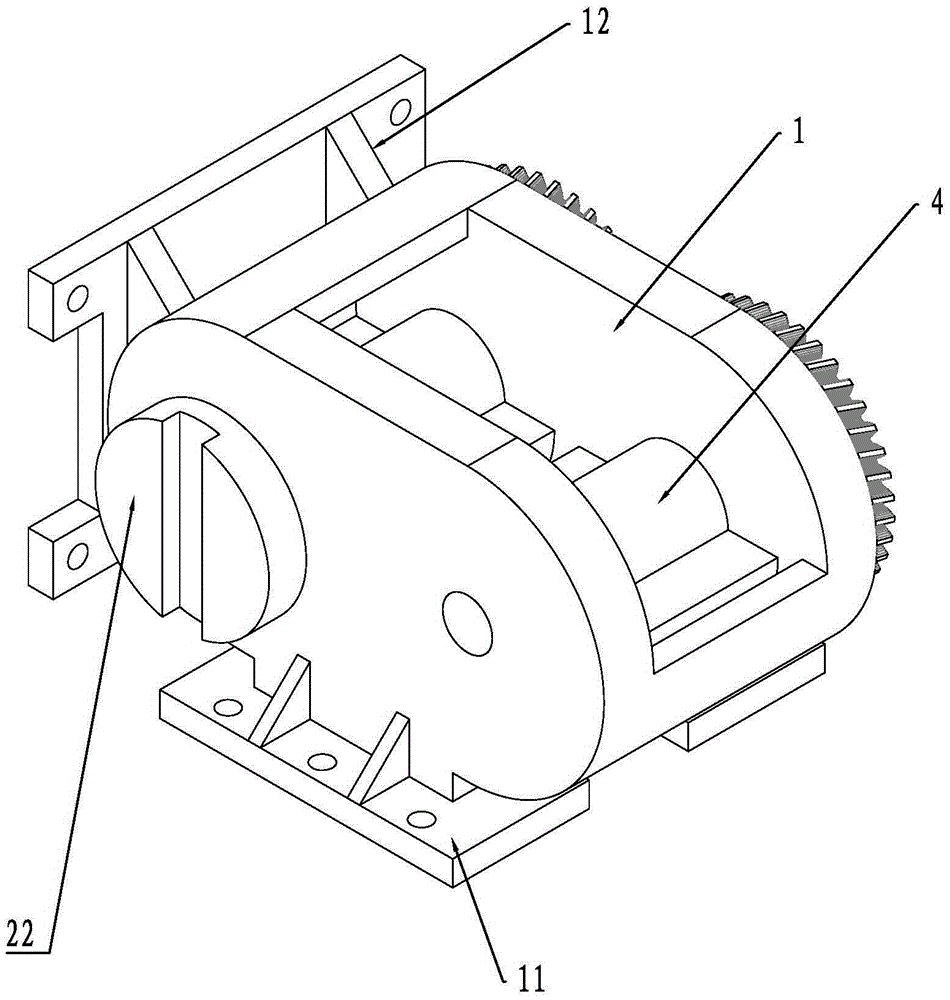

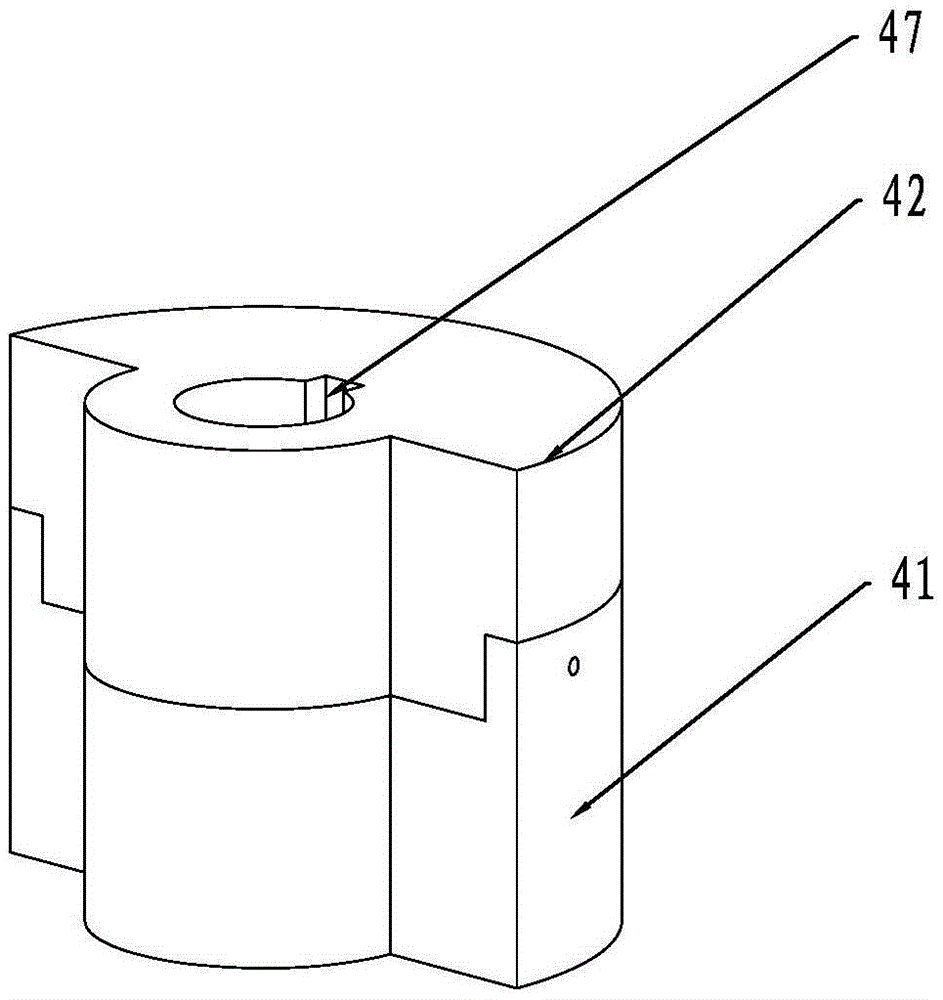

[0032] Such as figure 1 , figure 2 As shown, the mechanical vibration exciter of the present invention includes a support base 1, a driving shaft 2, a driven shaft 3, and an excitation block 4. The bottom of the support base 1 is provided with an installation base plate 11, and one side wall is provided with an installation side plate 12. Bottom plate 11 and installation side plate 12 and support seat 1 can adopt welding mode to be fixed or integrally made, and installation base plate 11 and installation side plate 12 are respectively provided with mounting holes 13,14, and mounting holes can be bolt holes or pin holes. The driving shaft 2 and the driven shaft 3 are respectively installed on the support base 1, the driving shaft 2 and the driven shaft 3 are connected by transmission, the transmission mode can be gear transmission or sprocket chain transmission, etc., the figure shows the gear transmission, the driving shaft Drive gear 21 is installed at one end of 2, and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com