Vibration ageing method for ship body

A vibration aging and hull technology, applied in the direction of improving process efficiency, can solve the problems of unreachable hull residual stress, unfeasible hull thermal aging, and inability to eliminate residual stress on the hull, and achieve a solution to the quality of the hull. Hidden problems, elimination of residual stress, and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

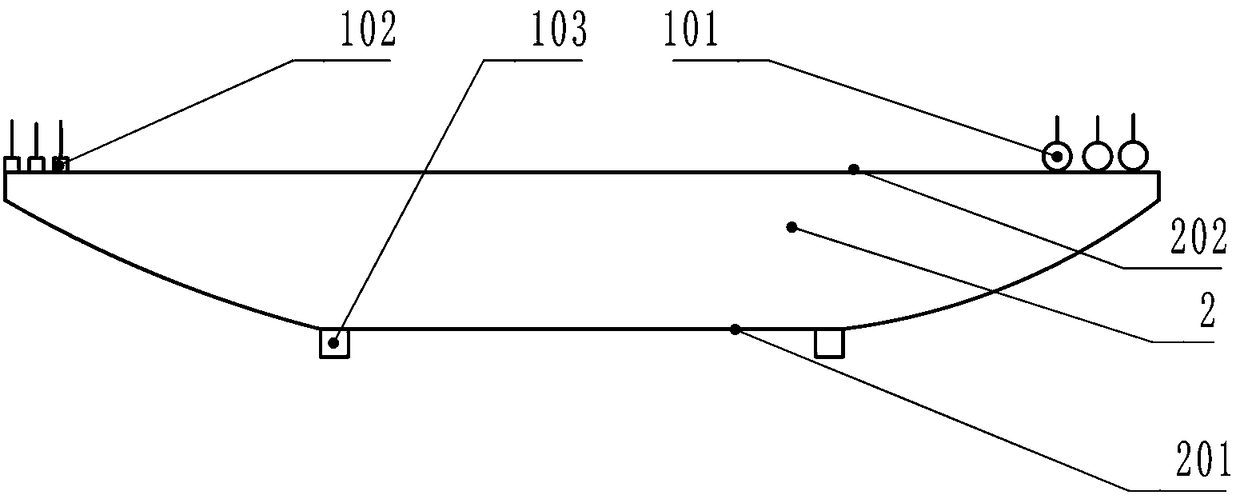

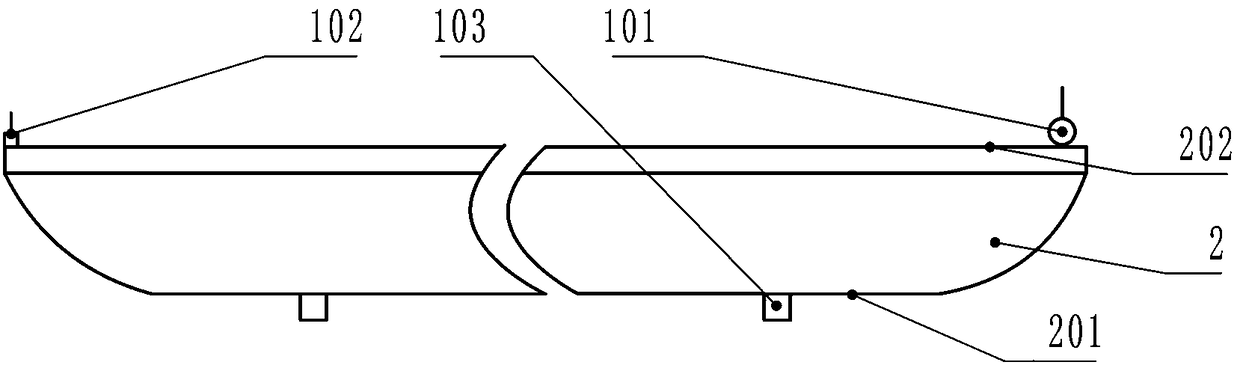

[0015] figure 1 The hull 2 shown has a deck 202 with two end corners at each end and a bottom 201 below the deck 202 . The vibration aging method of the hull is as follows: use 4 support pads 103 to place between the bottom 201 and the ground to keep the deck 202 level; Near the edge of a corner diagonal line, use two exciters 101, including the following steps:

[0016] The first step, two vibrators 101 are fixed on the other end of the same end angle diagonal line of the vibrator 102 on the deck 202 of the hull 2 along the hull length direction, so that each vibrator 101 The motors rotate in the same direction, and the two exciters 101 are placed adjacent to each other; in this way, the excitation force of the exciter can be doubled at the same position and in the same direction;

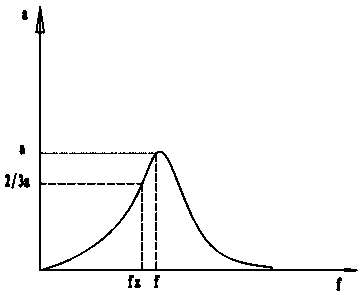

[0017] The second step, start the vibrator 101, control the vibration frequency of each vibrator 101 to be the sub-resonance frequency fz of the hull 2, and the two vibrators 101 simultaneou...

Embodiment 2

[0019] Three vibrators 102 are placed on the edge of one end of the ship deck 202 near a corner diagonal line along the length direction of the hull, and three vibrators 101 are used, including the following steps:

[0020] The first step, three vibrators 101 are fixed on the other end of the same end angle diagonal line of the vibrator 102 of the ship deck 202 of the hull 2 along the hull length direction, so that each vibrator 101 The direction of rotation of the motors is the same, and the three exciters 101 are placed adjacent to each other; in this way, the exciting force of the exciters can be doubled at the same position and in the same direction;

[0021] The second step, start the vibrator 101, control the vibration frequency of each vibrator 101 to be the sub-resonance frequency fz of the hull 2, and the three vibrators 101 simultaneously perform the same frequency resonance, and perform vibration aging on the hull 2 Treatment; the vibration aging treatment time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com