Vibrating type power head device

A power head and vibration-type technology, which is applied in the driving device of rotary combined drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems of unstable vibration box excitation force, many eccentric component parts, and large spindle damage. Achieve the effect of saving process, stable and reliable vibration, and reducing equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

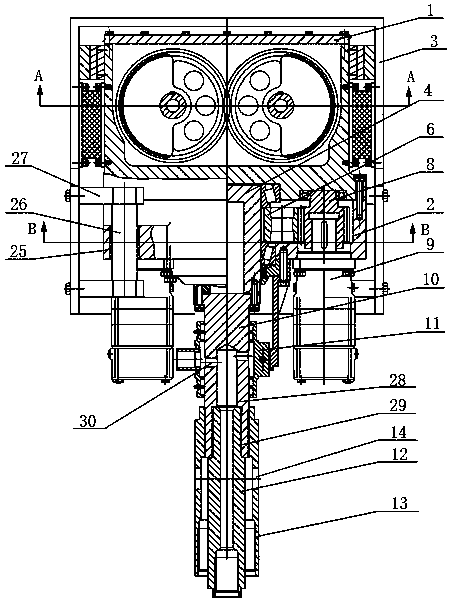

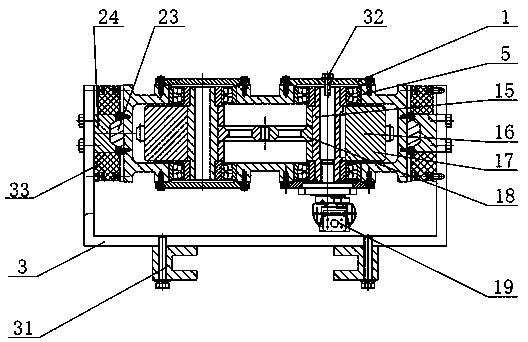

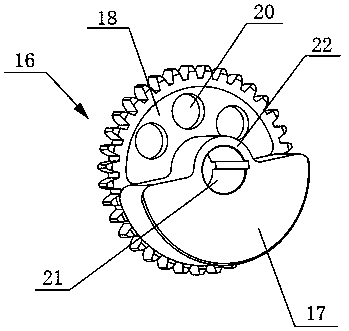

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings. For the convenience of description, in the drawings, the drill head of the drilling tool is designated as the front, that is, figure 1 The downward direction in is the front; specify that the direction of the main shaft 4 in the gearbox 2 is the axial direction of the entire device.

[0025] Such as figure 1 As shown, the vibrating power head device of the present invention includes a vibrating assembly and an outer casing 3 arranged outside it, a guide mechanism is arranged between the vibrating assembly and the outer casing 3, the vibrating assembly includes a vibrating box 1 and a gear box 2, and the gear The front end of the box 2 is connected to the drilling tool through the output joint 10, and the rear end is detachably connected to the vibration box 1. The vibrating box 1 is fixedly connected with the left and right inner surfaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com