Adjustable multifunctional excitation device of vibratory roller

A technology of vibratory road rollers and excitation devices, applied in roads, roads, road repairs, etc., can solve problems such as a single vibration mode, and achieve the effect of less rolling times, reasonable design, and good compaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

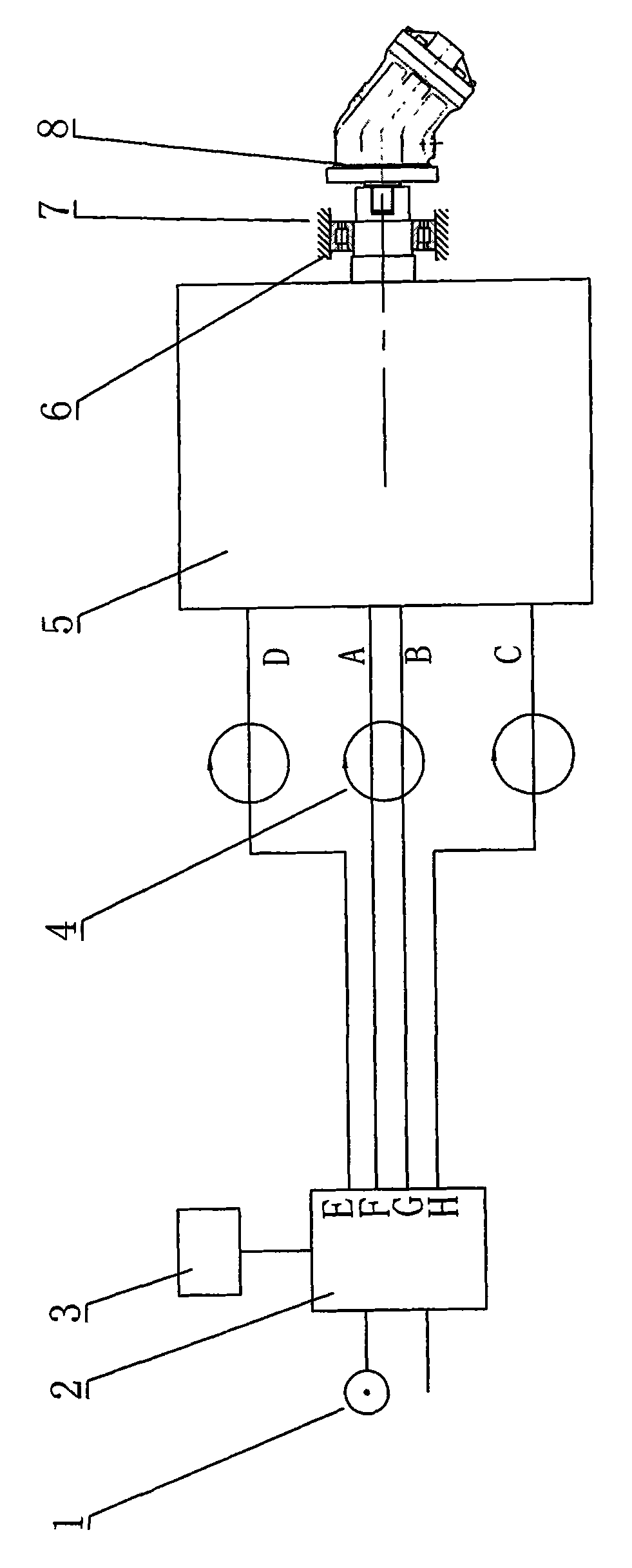

[0022] exist figure 1 Among them, the adjustable multifunctional vibration excitation device of the vibratory roller in this embodiment is connected by a hydraulic pump 1, a valve 2, a controller 3, a rotary joint 4, an exciter 5, a bearing 6, a vibration wheel 7 of the vibratory roller, and a hydraulic motor 8 constitute.

[0023] The exciter 5 is installed in the vibrating wheel 7 of the vibratory roller, and a bearing 6 is installed between the shaft of the vibrator 5 and the vibrating wheel 7 of the road roller, and a hydraulic motor 8 is fixedly connected to the end of the vibrator 5 with a coupling , the hydraulic motor 8 communicates with the hydraulic pump 1 of the vibratory roller through a pipeline, and the hydraulic motor 8 drives the vibrator 5 to rotate. The valve 2 communicates with the hydraulic pump 1 of the vibratory roller through a pipeline. The hydraulic pump 1 provides pressure oil. The valve 2 is an electromagnetic valve. The valve 2 is connected to the ...

Embodiment 2

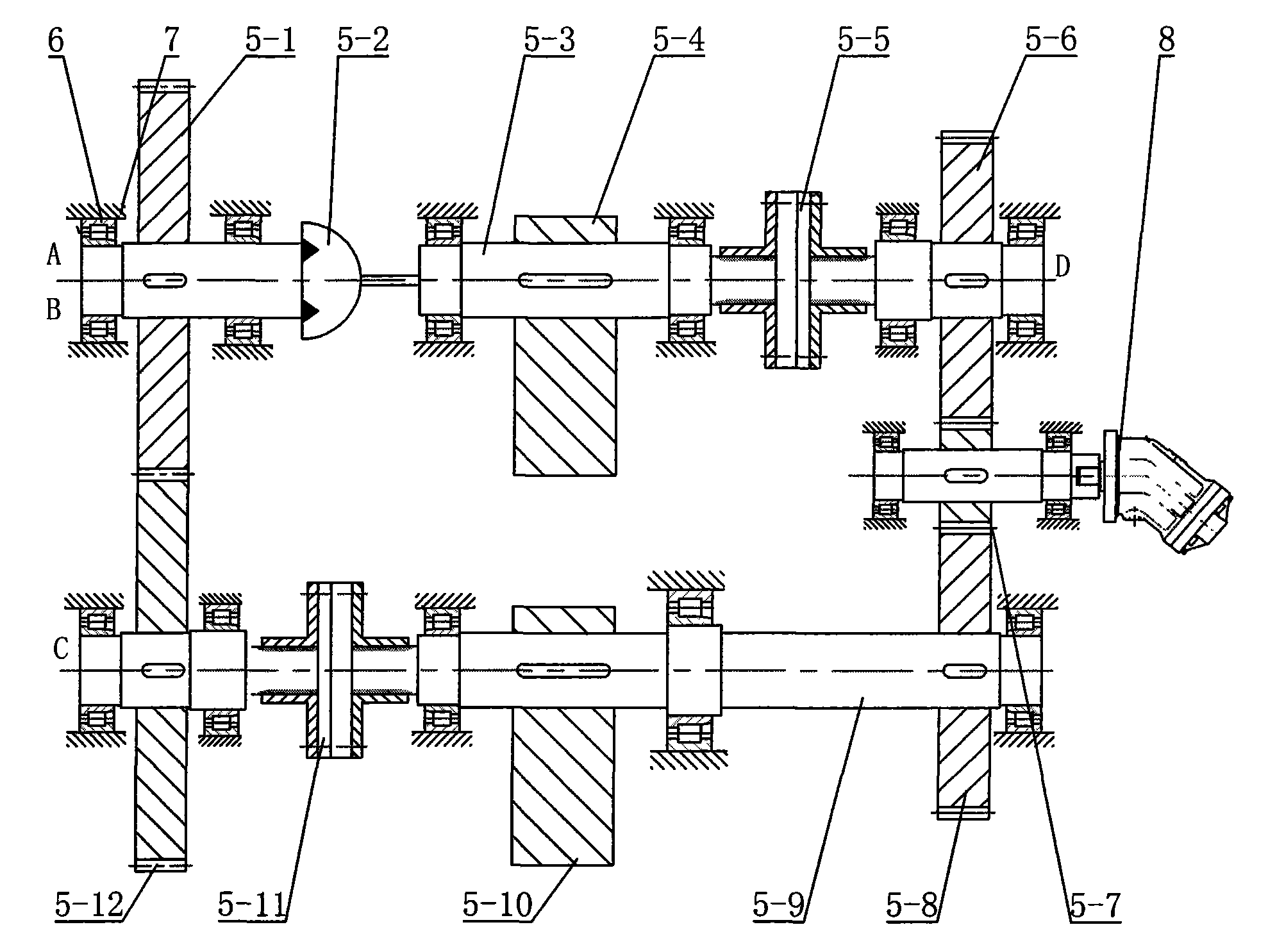

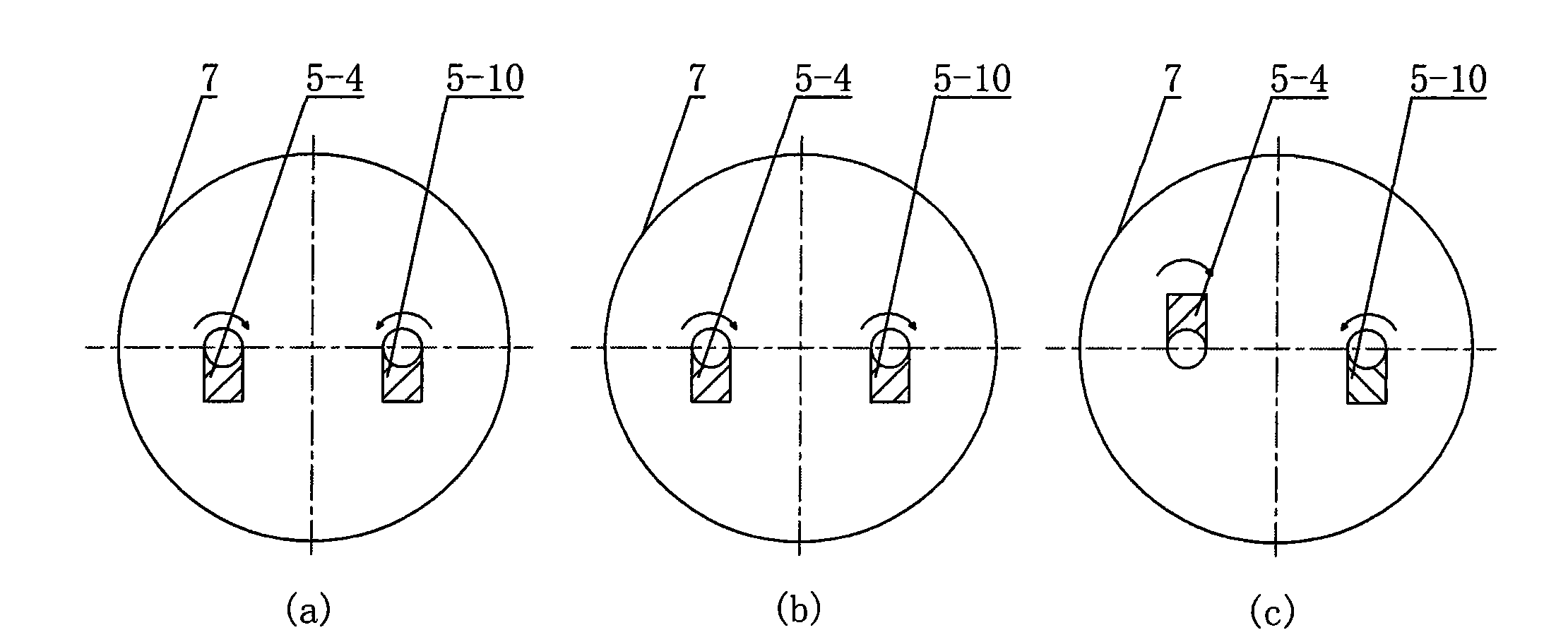

[0028] In this embodiment, the primary drive shaft 5-3 is splined with a primary clutch 5-5 and a primary eccentric block 5-4, and the primary clutch 5-5 is located between the primary eccentric block 5-4 and Between the first-stage forward gear 5-6, the distance between the installation axis of the first-stage eccentric block 5-4 and the center of gravity line is 5mm, and the mass of the first-stage eccentric block 5-4 is 200kg. The secondary drive shaft 5-9 is spline-connected with a secondary clutch 5-11 and a secondary eccentric block 5-10, and the secondary eccentric block 5-10 is located at the secondary forward gear 5-8 and the secondary clutch Between 5-11, the distance between the installation axis of the secondary eccentric block 5-10 and the center of gravity is 5mm, the mass of the secondary eccentric block 5-10 is 200kg, and the geometry of the secondary eccentric block 5-10 is the same as that of the primary The geometric shapes of the stage eccentric blocks 5-4 ...

Embodiment 3

[0030]In this embodiment, the primary drive shaft 5-3 is splined with a primary clutch 5-5 and a primary eccentric block 5-4, and the primary clutch 5-5 is located between the primary eccentric block 5-4 and Between the first-stage forward gears 5-6, the distance between the installation axis of the first-stage eccentric block 5-4 and the center of gravity line is 500 mm, and the mass of the first-stage eccentric block 5-4 is 0.5 kg. The secondary drive shaft 5-9 is spline-connected with a secondary clutch 5-11 and a secondary eccentric block 5-10, and the secondary eccentric block 5-10 is located at the secondary forward gear 5-8 and the secondary clutch Between 5-11, the distance between the installation axis of the secondary eccentric block 5-10 and the center of gravity is 500mm, the mass of the secondary eccentric block 5-10 is 0.5kg, and the geometric shape of the secondary eccentric block 5-10 is consistent with The geometric shapes of the first-level eccentric block 5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com