Large-span vibrator

A vibration exciter, a large-span technology, applied in chemical instruments and methods, fluid and solid separation using vibration, etc., can solve the problems of occupying the effective space above the screen surface, difficult to be greatly improved, and difficult to improve. , to achieve the effect of convenient manufacturing and installation, simple structure and improved cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

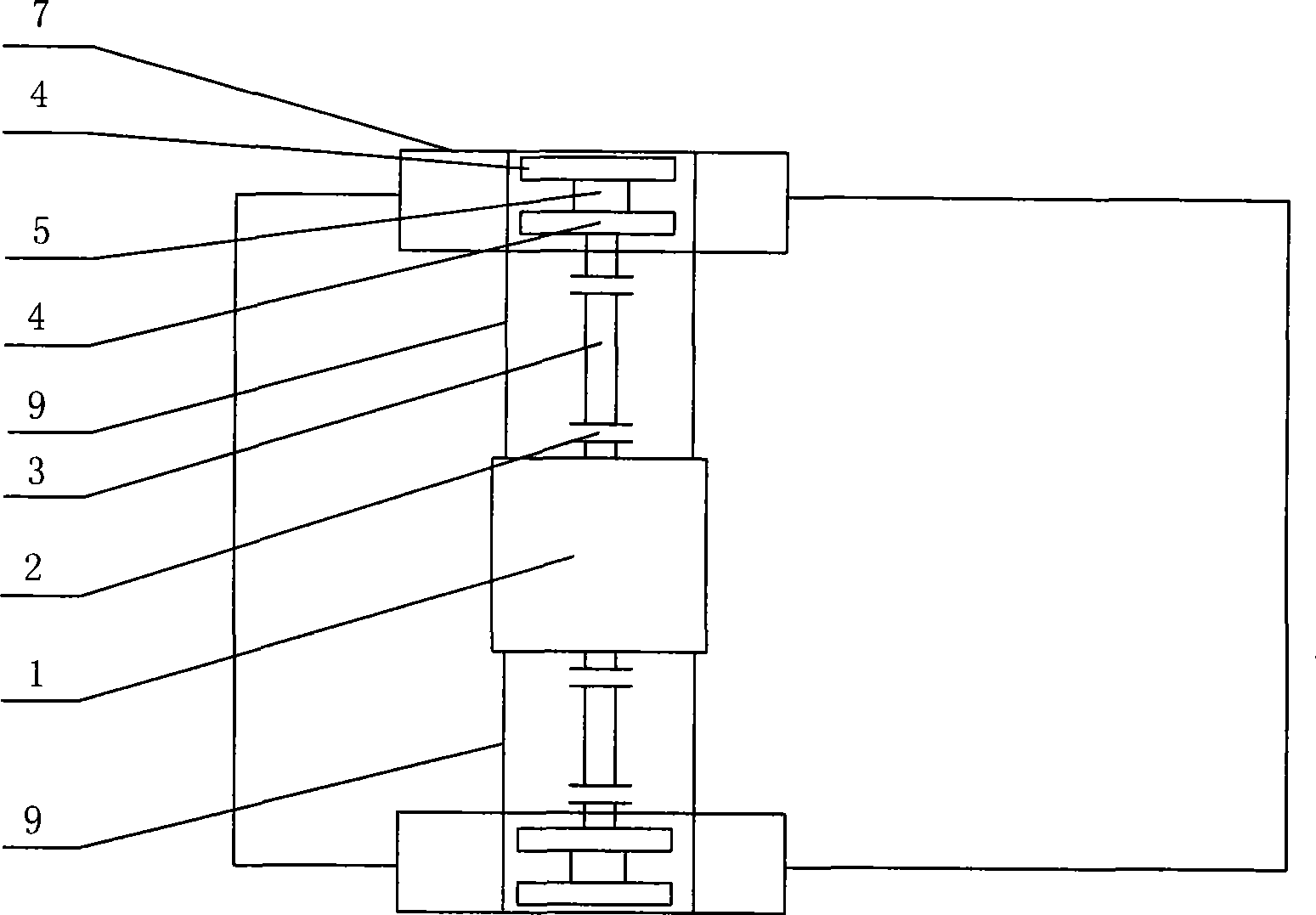

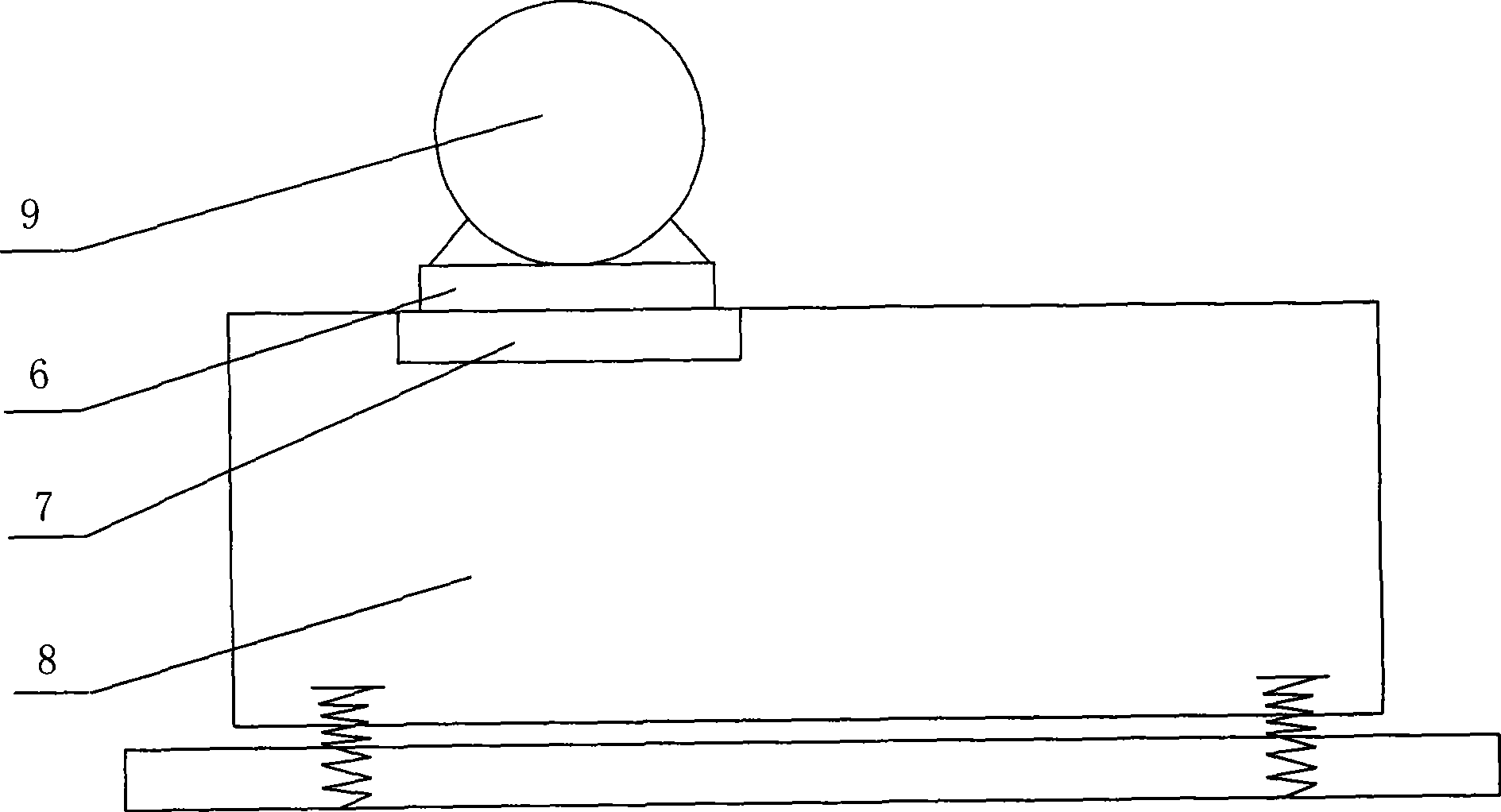

[0014] A large-span vibration exciter, including a vibrating screen and a motor, the motor adopts an anti-vibration motor 1, and the two ends of the anti-vibration motor 1 are connected with a universal joint transmission shaft 3 through a coupling 2, and the universal joint transmission shaft 3 is connected through a coupling The shaft device 2 is connected with two eccentric mass blocks 4, and the eccentric mass block 4 is supported on the motor base 7 of the side plate 8 of the screen box through the bearing 5 and the bearing seat 5; The elongated cylinder parts 9 connected at the ends are connected to form a whole. Wherein, the anti-vibration motor 1 is an explosion-proof anti-vibration motor. Since the anti-vibration motor used in this vibrator is not directly connected to the eccentric mass 4, the entire anti-vibration motor 1 is not directly affected by the radial centrifugal excitation force generated by the rotation of the eccentric mass 2. Therefore, the load on the...

Embodiment 2

[0016] The vibration motor 1 in the first embodiment is a non-flameproof and anti-vibration motor.

Embodiment 3

[0018] A large-span vibration exciter, including a vibrating screen and a motor, the motor adopts an anti-vibration motor 1, and the two ends of the anti-vibration motor 1 are connected with a universal joint transmission shaft 3 through a coupling 2, and the universal joint transmission shaft 3 is connected through a coupling The shaft device 2 is connected with two eccentric mass blocks 4, and the eccentric mass block 4 is supported on the motor base 7 of the side plate 8 of the screen box through the bearing 5 and the bearing seat 6; The elongated cylinder parts 9 connected at the ends are connected as a whole. Wherein, the anti-vibration motor 1 is an explosion-proof anti-vibration motor. The vibrator adopts frequency conversion to start, that is, starts at a low speed, and gradually reaches the rated operating speed for the stable operation of the vibrating screen, which can achieve the purpose of saving energy. The vibrating screen uses three exciters to vibrate at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com