Stress testing device for non-metal anti-floating anchor rod body

An anti-floating anchor rod and stress testing technology, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, can solve the problems of easy falling off of the strain gauge, low spatial resolution, missing data, etc., and achieve anti- Strong electromagnetic field interference ability, high measurement accuracy and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

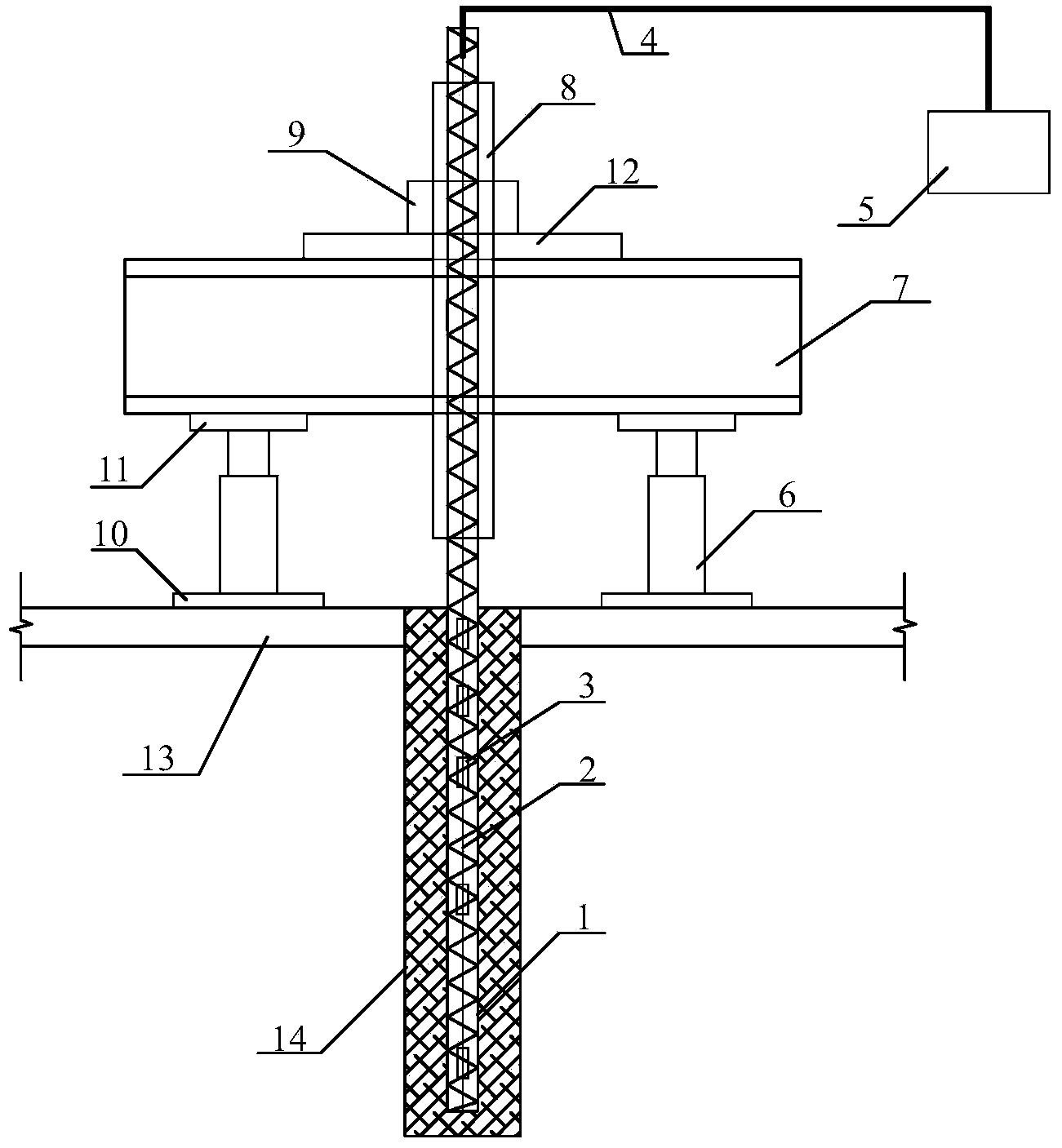

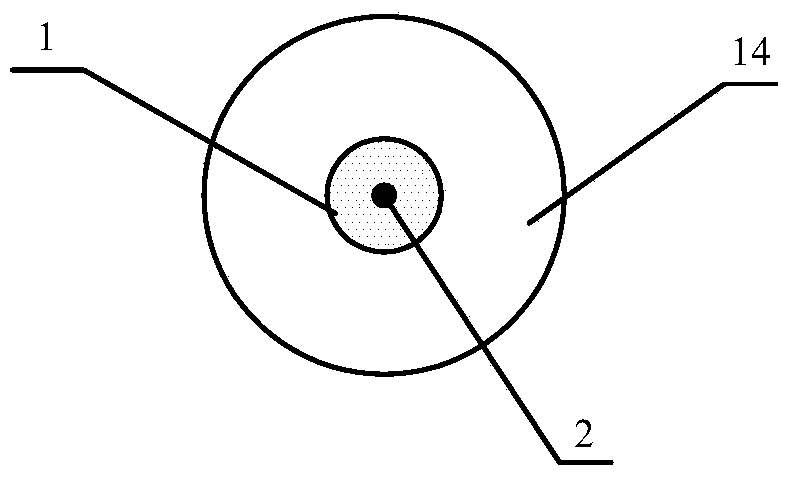

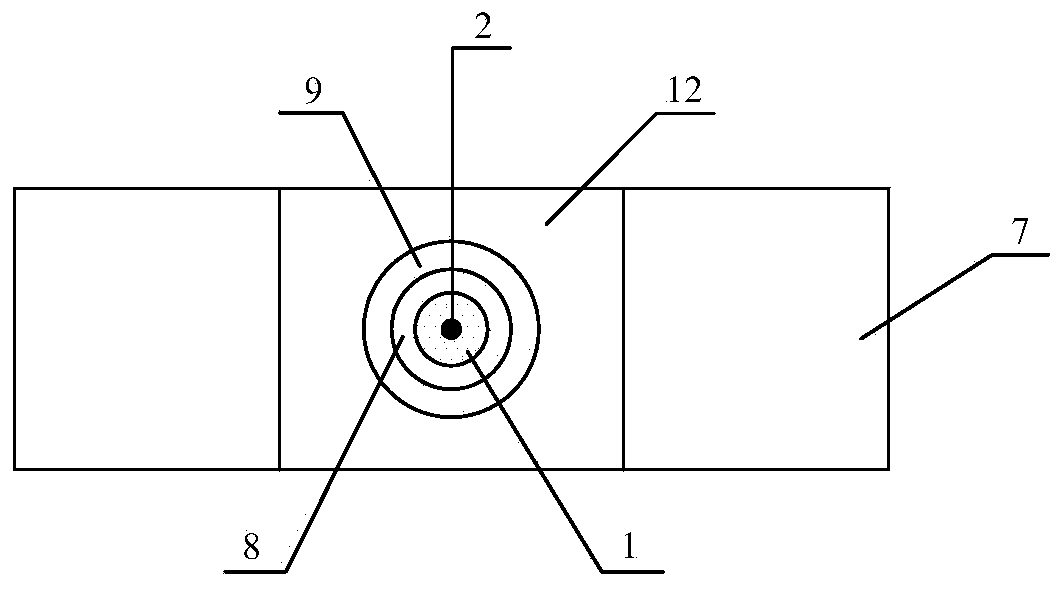

[0021] The main structure of this embodiment includes an anchor rod body 1, a bare optical fiber 2, a grating sensor 3, an armored optical cable 4, a data acquisition system 5, a jack 6, a reaction beam 7, a steel sleeve 8, an anchor 9, and a first steel plate 10. The second steel plate 11, the third steel plate 12, the cushion layer 13 and the anchor hole 14; the lower end of the glass fiber reinforced polymer (GFRP) fully threaded solid structure anchor body 1 is inserted into the anchor hole 14; the bare optical fiber 2 The grating sensor 3 is engraved to form a bare fiber grating string, and the middle part of the anchor rod 1 is buried with a fiber grating string along the length direction. The outer surface coating of the bare optical fiber 2 is a polymer that has fusion properties with the anchor rod body 1; The bare optical fiber 2 at the end of the rod body 1 is protected by an armored optical cable 4, and the armored optical cable 4 is connected to the data acquisitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com