Preparation method of fiber grating

A technology of fiber gratings and fiber prefabricated rods, which is applied in the direction of cladding optical fibers, optical waveguides, light guides, etc., which can solve the problem of laser beam uniformity, laser pulse stability, laser beam aiming point stability, low coherence, and low quality of grating arrays. , affect the consistency of the grating and other issues, to achieve the effect of high reflectivity consistency, simple and reasonable process, good uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

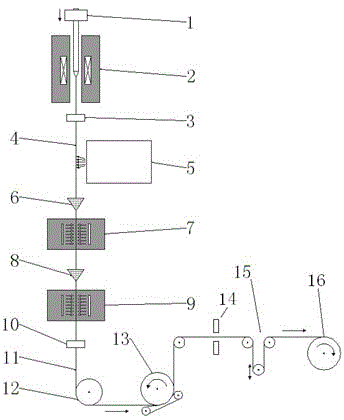

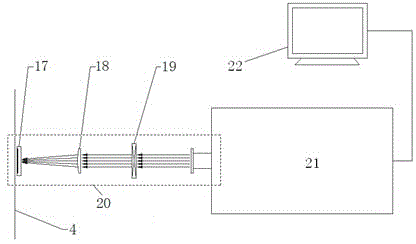

Method used

Image

Examples

specific Embodiment 1

[0026] Specific embodiment 1: Under the condition of stable fiber drawing with fiber drawing speed of 25m / min and fiber drawing tension of 50 grams, a 193nm laser with a grid pitch of 1071nm and a laser pulse energy of 10mJ is used on a bare fiber with a core refractive index of 1.4567 A weak grating array with a pitch of 1 m is prepared. After the fiber drawing process is stable (speed 25m / min, tension 50g), the laser adopts external control, and the 1m spacing set by the basic distance measurement program requires a pulse command to be sent to the laser, and the laser generates a laser pulse when receiving the pulse command , the pulse width of the laser is 4ns, and the laser pulse is adjusted from 4 mm × 6 mm to a spot of 1 mm × 10 mm through the beam expander lens group, and the grating with a length of 10 mm is written on the bare fiber, and then it is coated by the first stage / UV curing and secondary coating / UV curing realize optical fiber coating, so as to effectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com