Method for continuously preparing fiber gratings on line

A fiber grating and grating technology, applied in the direction of cladding fiber, optical waveguide light guide, etc., can solve the problems of poor reliability of fiber grating, poor consistency of fiber background temperature, etc., to eliminate mutual constraints, high-precision control of bare fiber diameter, The effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] Embodiments of the present invention will be described with reference to the drawings. In addition, in description of drawings, the same code|symbol is attached|subjected to the same unit, and repeated description is abbreviate|omitted.

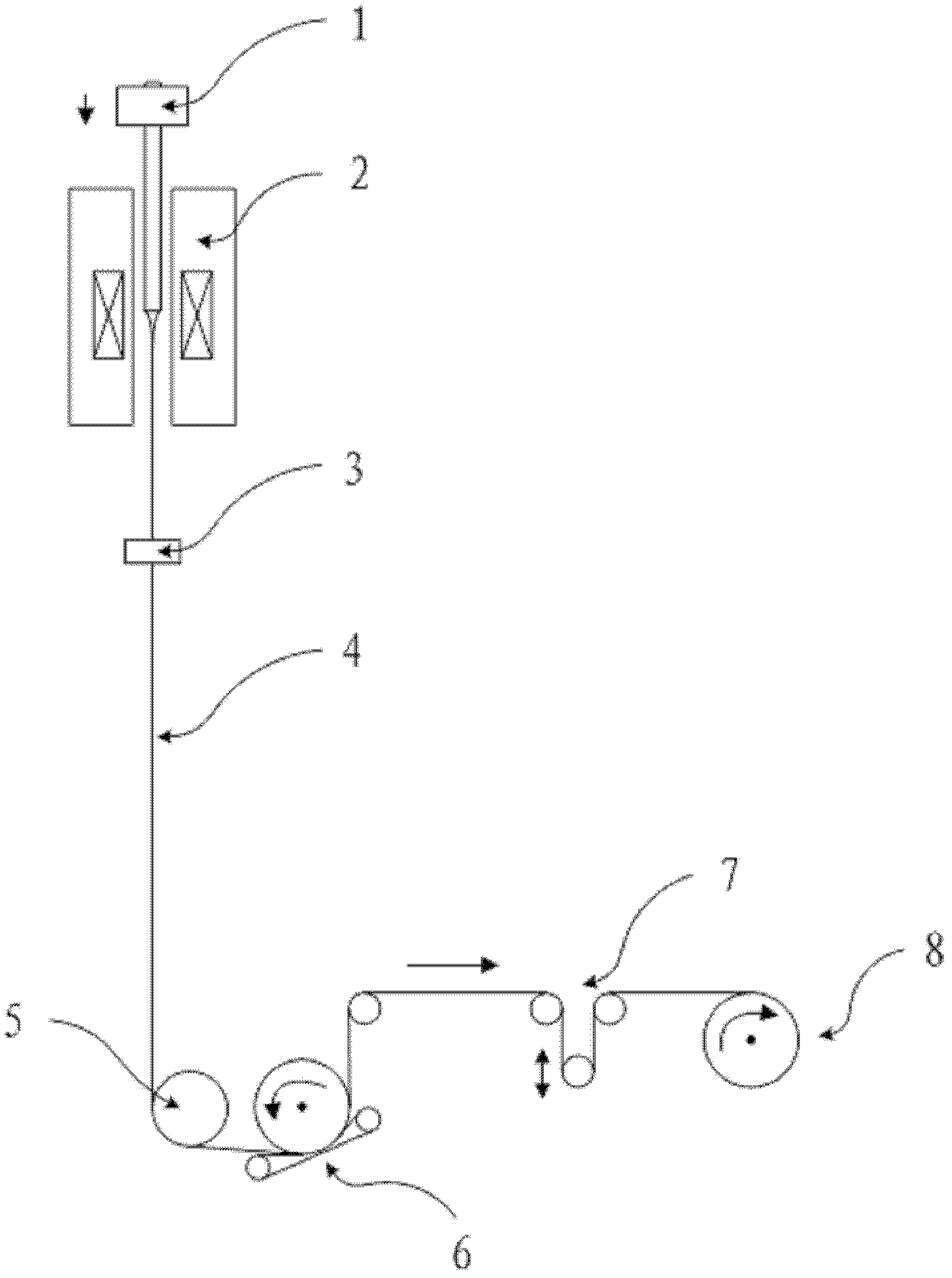

[0026] figure 1 Schematic drawing and take-up of bare optical fiber. This process is basically the same as conventional optical fiber drawing, the only difference is that there is no coating and curing process for optical fiber protective layer. Under the action of high temperature in the wire drawing furnace 2, the lower end of the preform is melted and taped to form a wire, and is drawn into the wire drawing wheel 6 through the tension measuring instrument 5 to form a bare optical fiber; the diameter of the bare optical fiber is monitored by the bare optical fiber caliper 3 and the prefabrication is controlled by real-time feedback The speed of the rod feeding device 1 and the bare optical fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com