Temperature self-compensation fiber grating displacement sensor

A technology of displacement sensor and optical fiber grating, which is applied in thermometers, optical devices to transmit sensing components, and thermometers with physical/chemical changes. , measurement signal instability and other problems, to achieve the effect of simple structure, good long-term stability and large measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

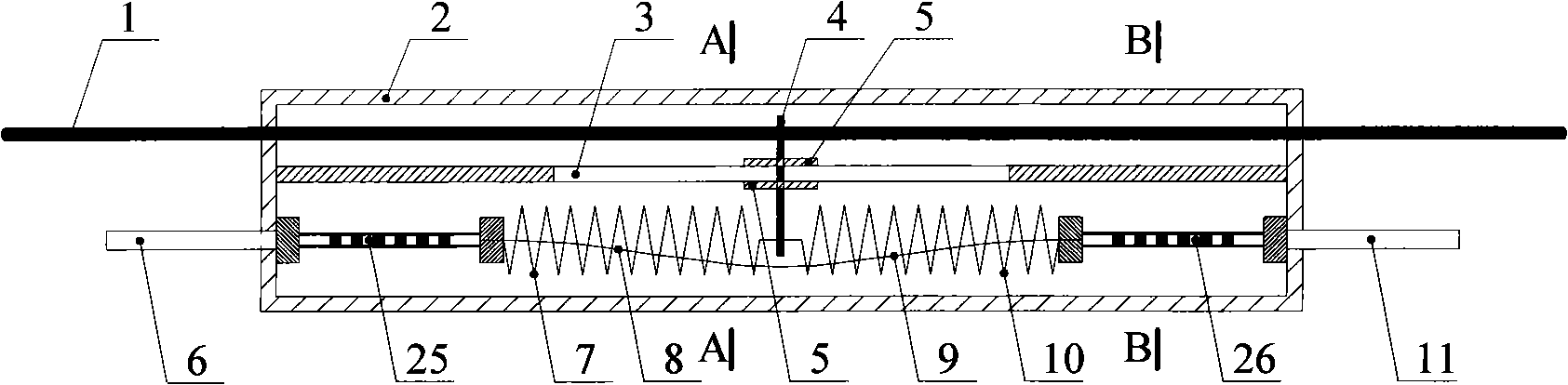

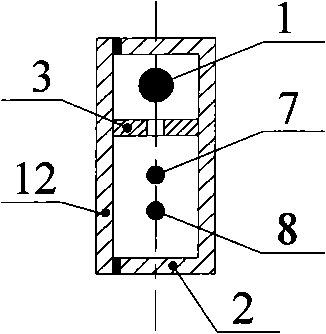

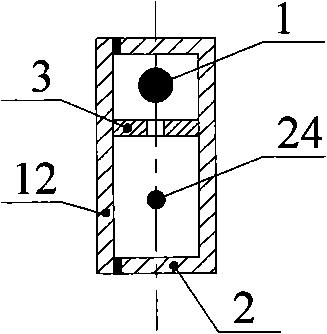

[0022] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0023] Such as Figure 1 to Figure 10 As shown, the temperature self-compensating fiber grating displacement sensor of the present invention includes a probe 1, a metal box 2, a partition 3, a connecting rod 4, a limit plate 5, a first pigtail 6, a left spring 7, a second pigtail 8, a Three pigtails 9, right spring 10, fourth pigtail 11, metal box cover 12, guide rod hole 13, first small hole 14, left metal connection block 15, capillary metal tube 16, epoxy resin 17, right metal connection Block 18, bare fiber grating 19, partition plate long hole 22, the second small hole 23, the third small hole 24, the first fiber grating sensor 25, the second fiber grating sensor 26; wherein, the partition plate 3 is horizontally arranged in the metal box 2, the left and right ends and the bottom are fixed to the inner wall of the metal box 2, and the metal box 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com