A fiber optic efpi ultrasonic sensor

A sensor and ultrasonic technology, applied in the direction of measuring ultrasonic/sonic/infrasonic waves, instruments, using wave/particle radiation, etc., can solve problems such as inaccurate measurement results, temperature drift, etc., to improve accuracy and reliability, and simple structure , The effect of facilitating engineering construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structure and working principle of the optical fiber EFPI ultrasonic sensor involved in the present invention will be further elaborated below with specific embodiments:

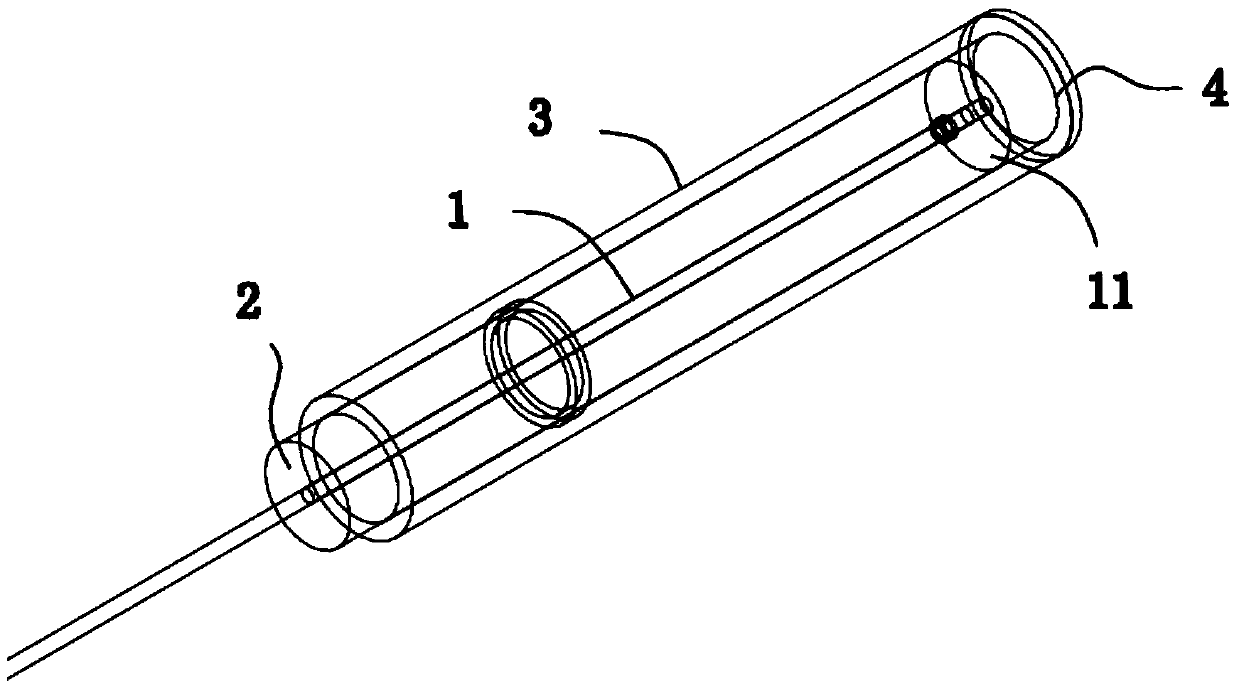

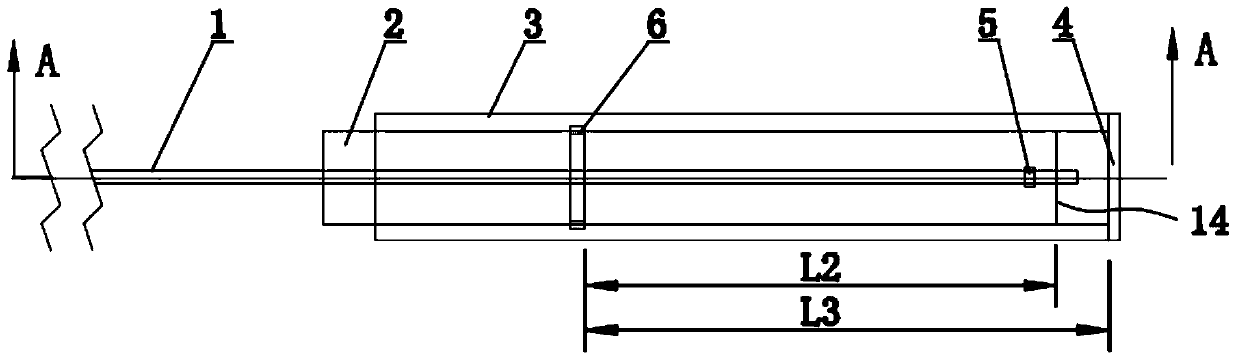

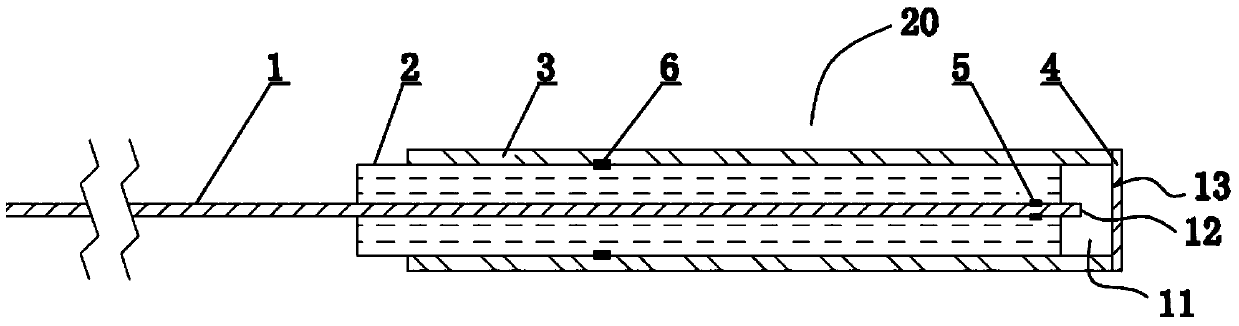

[0026] see Figure 1 to Figure 3 As shown, a fiber optic EFPI ultrasonic sensor 30 is provided in this embodiment, including a sensor head unit 20 and a sensor body unit, the sensor body unit includes a sensor sheath 9, and the sensor head unit 20 is arranged on the sensor sheath 9 Inside, the sensor head unit 20 includes a capillary 3 and a part of the optical fiber 1 arranged in the capillary 3 and a ferrule bracket 2 for fixing the optical fiber 1, and a film for sensing ultrasonic vibration is also arranged on one end of the capillary 3 A sheet 4, the inner surface 13 of the diaphragm 4, the front end surface 12 of the optical fiber 1 and the inner surface of the capillary 3 are jointly defined to form a Fabry-Pérot cavity 11, and the front end surface 12 of the optical fiber 1 constitutes the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com