A fiber f-p composite cavity type high temperature strain sensor

A high-temperature strain, F-P technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of slow measurement rate, limited application, large error, etc., and achieve the effect of high precision and high measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

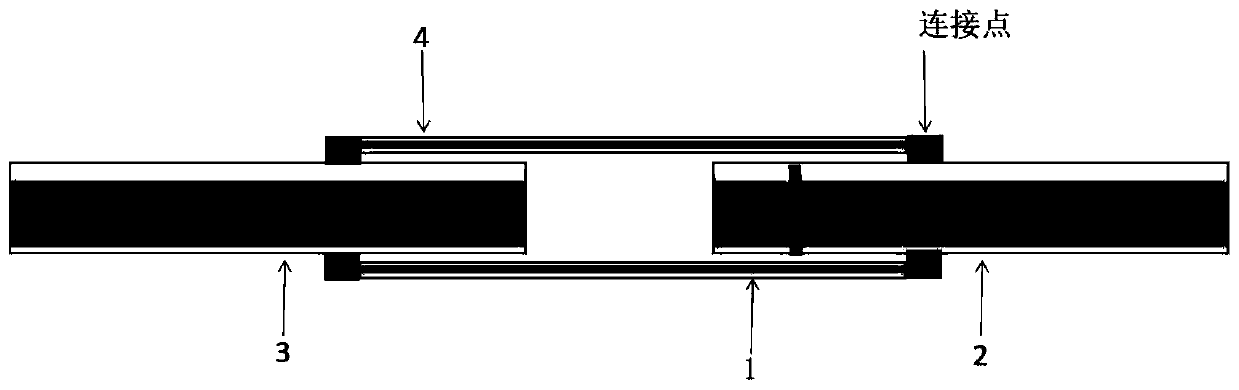

[0019] In the embodiment of the present invention, an optical fiber F-P composite cavity type high-temperature strain sensor is provided, which includes a first single-mode optical fiber 1, a second single-mode optical fiber 2, a multi-mode optical fiber 3, and a capillary glass tube 4 with openings at both ends. The length of the single-mode optical fiber 1 is 100-150 microns. The material of the first single-mode fiber 1, the second single-mode fiber 2, and the multimode fiber 3 is fused SiO 2 . One of the flat end surfaces of the first single-mode optical fiber 1 is coated with a dielectric reflection film with a fixed reflectivity, and the material of the dielectric reflection film is TiO 2 or TiO 2 / SiO 2 The compound is used to increase t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com