Drawbench for carbon steel metal material

A technology of metal materials and wire drawing machines, which is applied in the direction of metal wire drawing, wire drawing dies, metal processing equipment, etc., and can solve the problems of troublesome loading and unloading, long heating, heat preservation and cooling time, waste products and broken wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

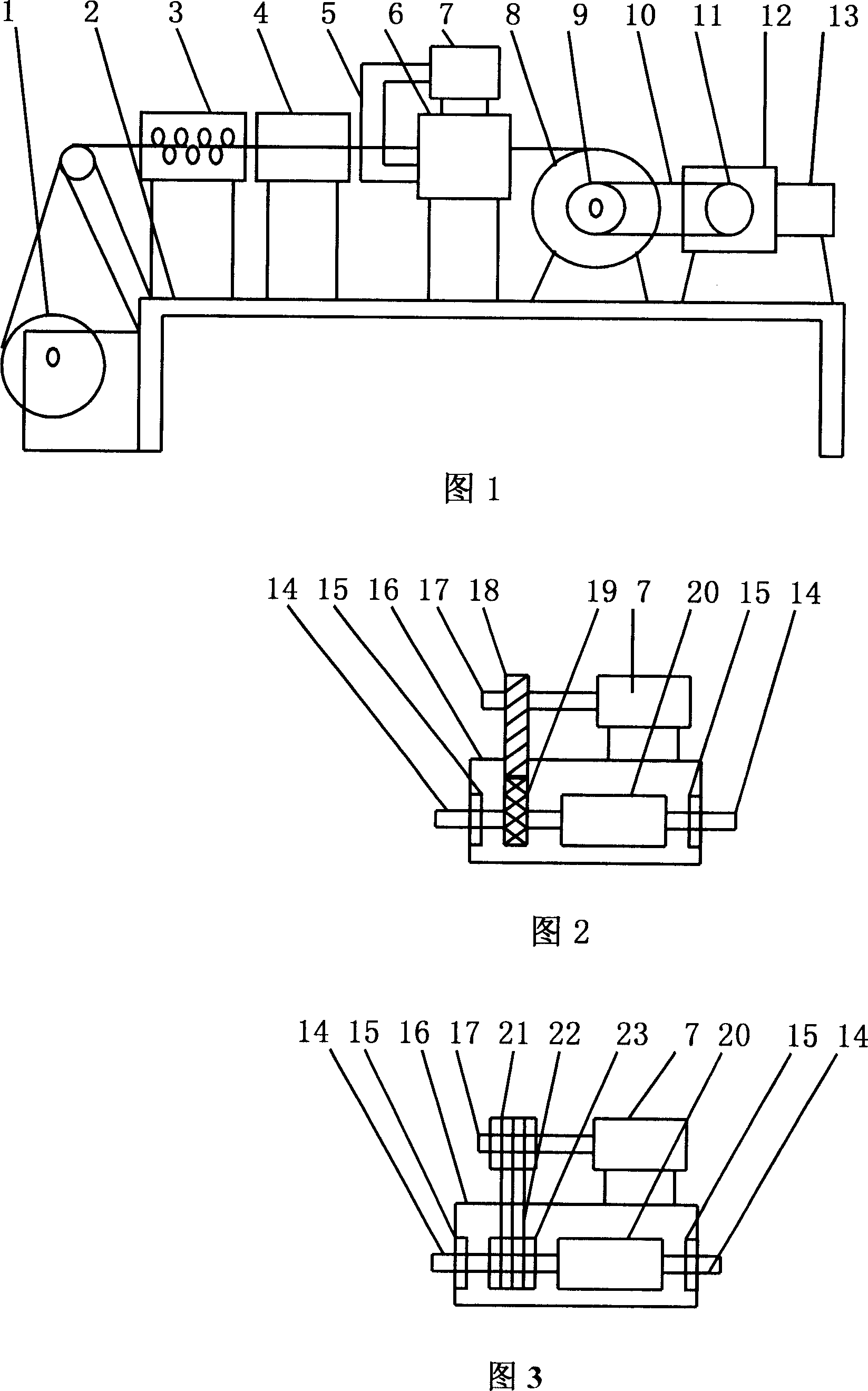

[0017] A wire drawing machine for carbon steel metal materials, as shown in Figure 1: a pay-off frame 1, a straightening machine 3, a wire drawing die device 6, a wire receiving frame 8, a speed regulating device 12 and a large motor 13 are fixed sequentially from left to right On rack 2. The large motor 13 is connected with the speed regulating device 12, and the speed regulating device 12 is connected with the wire receiving frame 8 through the belt pulley B11, the belt A10 and the belt pulley A9. An induction heater 4 is also installed on the frame 2 between the straightening machine 3 and the drawing die device 6 . Bearings 15 are housed at the left and right ends of the wire drawing die box 16 of the wire drawing die device 6 . The wire drawing die box 20 left and right ends that are contained in the wire drawing die box 16 are equipped with shaft rollers 14, and the two ends shaft rollers 14 are all mounted on the wire drawing die box 16 by bearings 15 at both ends. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com