Wire rod pickling-free drawing production process

A production process, no pickling technology, used in manufacturing tools, metal processing equipment, metal extrusion cleaning equipment, etc., can solve the problems of accelerated hydrogen residue discharge, low production efficiency, environmental impact, etc., to solve production costs and The effect of environmental pollution, improving production efficiency and improving drawing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

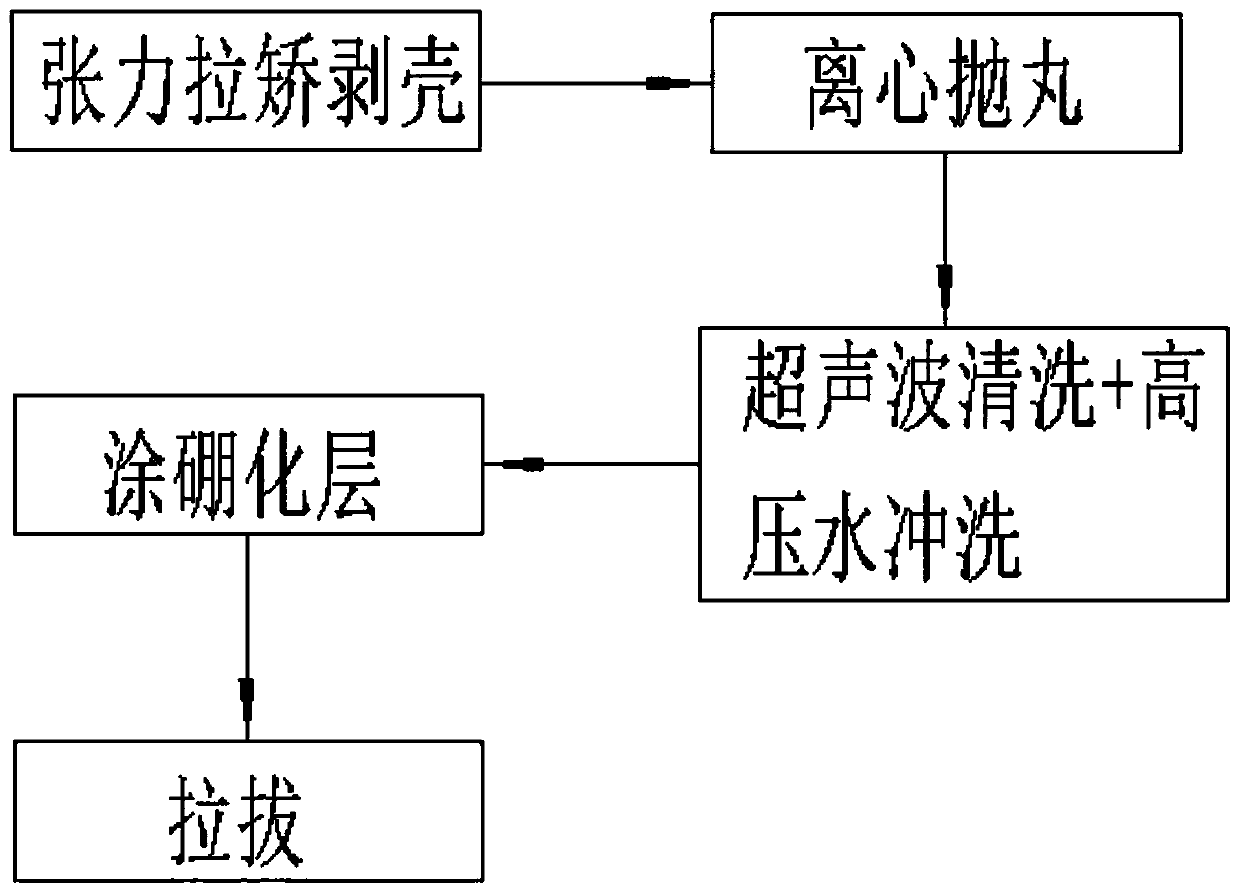

[0023] A production process for wire rod and wire rod without pickling and drawing, comprising the following steps:

[0024] Step 1. Tension tension leveling and shelling: Select the wire rod of the corresponding specification and place it on the pay-off rack, use the tension tension leveler to remove the coarse oxide layer on the outside of the wire rod, and obtain the shelled steel rod, then use the I-shaped wheel for random collection Wire;

[0025] Step 2. Centrifugal shot blasting: evenly disperse the shelled steel bars of the whole plate, select wear-resistant metal balls with a diameter of 0.4mm at a throwing speed of 85m / s and a throwing frequency of 55Hz, and the centrifugal shot blasting time is 18min , and then remove the fine iron oxide skin on the surface of the steel bar;

[0026] Step 3. Ultrasonic cleaning + high-pressure water washing: Use an ultrasonic cleaning pool with tap water as the washing liquid to clean the dirt on the surface of the steel bar. The c...

Embodiment 2

[0030] On the basis of Embodiment 1, some improvements are made. The improvement points are: in step 1, the shelling wheel set of the tension tension leveler adopts a five-roller centralized wheel set, and the shelling wheel set is provided with three groups, three sets of shelling wheels The group is arranged in a 120° space, which can effectively remove the oxide layer on the surface of the wire rod at 360°, and increase the number of peeling times to reduce the thickness of each peeling to ensure the internal structure of the wire rod.

Embodiment 3

[0032] The improvement done on the basis of Example 2 is: in step 2, the shot blasting process is divided into positive and negative two-way shot blasting processes, firstly carry out forward shot blasting for 10s, and then carry out reverse shot blasting for the same time, so that The entire circumferential surface of the steel rod is thrown by wear-resistant metal balls to ensure that the oxide layer on the outer surface of the peeled wire rod is further removed. Combined with ultrasonic cleaning + high-pressure water washing, it provides conditions for the later coating of the boride layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com