A kind of high heat-resistant v-0 flame retardant PP for toilet lid and production method thereof

A high heat-resistant, toilet lid technology, applied in the field of polymer materials, can solve problems such as defect rate exceeding 30%, poor appearance and black spots, narrow processing range, etc., to improve production qualified product rate, reduce appearance defect rate, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

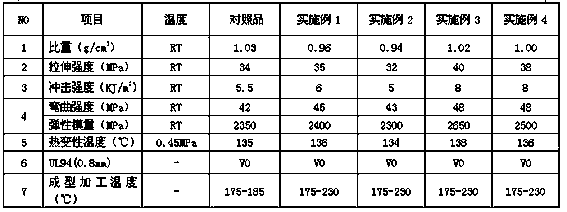

Examples

Embodiment 1

[0037] 1) Mix low-halogen flame retardant (tetrabromobisphenol A), organophosphorus flame retardant (RDP) and organic nitrogen flame retardant (melamine) at a ratio of 1:4:5, and pre-synthesize in a reactor to obtain a composite flame retardant agent, the reaction temperature is 200±10°C;

[0038] 2) Take 89 parts of copolymerized polypropylene or / and homopolypropylene (the melt index of copolymerized polypropylene and homopolypropylene is 50g / 10min under the test conditions of 230°C and 2.16KG), 10 parts of composite flame retardant, Add 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 0.2 part of ultraviolet absorber UV326, 0.1 part of light stabilizer UV944, and 0.5 part of calcium stearate, and add them to the mixer in turn, mix them thoroughly for 10 minutes, and put them into the twin-screw extruder The extruder is mixed and melted, and the processing temperature of the twin-screw extruder is: 150±5℃ in the first zone, 170±5℃ in the second zone, 180±5℃ in the t...

Embodiment 2

[0040] 1) Mix low-halogen flame retardant (tetrabromobisphenol A), organophosphorus flame retardant (RDP) and organic nitrogen flame retardant (melamine) at a ratio of 1:5:4, and pre-synthesize in a reactor to obtain a composite flame retardant agent, the reaction temperature is 200±10°C;

[0041] 2) 90 parts of copolymerized polypropylene or / and homopolypropylene (the melt index of copolymerized polypropylene and homopolypropylene is 10g / 10min under the test conditions of 230°C and 2.16KG), 8 parts of composite flame retardant, Antioxidant 1010 0.4 parts, antioxidant 1680.4 parts, antioxidant DSTP 0.4 parts, ultraviolet absorber UV326 0.2 parts, benzophenone 0.2 parts, light stabilizer UV944 0.1 parts, UV622 0.1 parts, polyethylene wax 0.1 parts , 0.1 parts of siloxane, added to the mixer in turn, after fully mixing for 10 minutes, put into the twin-screw extruder to mix and melt, the processing temperature of the twin-screw extruder is: 150±5℃ in the first zone, 170±5℃ in th...

Embodiment 3

[0043] 1) Mix low-halogen flame retardant (tetrabromobisphenol A), organophosphorus flame retardant (RDP) and organic nitrogen flame retardant (melamine) at a ratio of 1:4:5, and pre-synthesize in a reactor to obtain a composite flame retardant agent, the reaction temperature is 200±10°C;

[0044] 2) 83 parts of copolymerized polypropylene or / and homopolypropylene (the melt index of copolymerized polypropylene and homopolypropylene is 80g / 10min under the test conditions of 230°C and 2.16KG), 15 parts of composite flame retardant, Add 0.6 parts of antioxidant 1076, 0.6 parts of antioxidant 618, 0.1 parts of UV absorber UV531, 0.1 parts of light stabilizer UV622, 0.1 parts of UV770, and 0.5 parts of polyethylene wax. After 5 minutes, put it into the twin-screw extruder for mixing and melting. The processing temperature of the twin-screw extruder is: 150±5℃ in the first zone, 170±5℃ in the second zone, 180±5℃ in the third zone, 185±5℃ in the fourth zone, and 185±5℃ in the fifth z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com