Patents

Literature

52results about How to "Eliminate pitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mobile phone curved glass panel and forming method thereof

ActiveCN104023099AFit tightlyComfortable fitGlass reforming apparatusTelephone set constructionsEngineeringGraphite

The invention discloses a mobile phone curved glass panel and a manufacturing method of the mobile phone curved glass panel. A curved glass panel body is formed by bending a mobile phone panel body toward the same side in an arc shape with the center line of the mobile phone panel body in the X-axis direction or the Y-axis direction as a center, or bending the periphery of the mobile phone panel body toward the same side in an arc shape with the center point of the mobile phone panel as the center, or the mobile phone curved glass panel comprises a main panel and curved panels. The curved panels are formed by bending one or more side edges of the main panel. The multiple curved panels are bent toward the same side relative to the main panel. The forming method includes the three steps of manufacturing a planar glass panel, manufacturing a graphite die and forming the curved glass panel. The good lubricating performance of graphite is used, through exerting certain pressure for deformation, heat deformation is achieved at the temperature below a glass softening point, the manufactured product is high in precision, the designing requirements of a 3D mobile phone glass panel are met, large-scale industrial production can be achieved, production cost can be reduced, and the requirement for personalized and fashionable mobile phones can be met for people.

Owner:LENS TECH

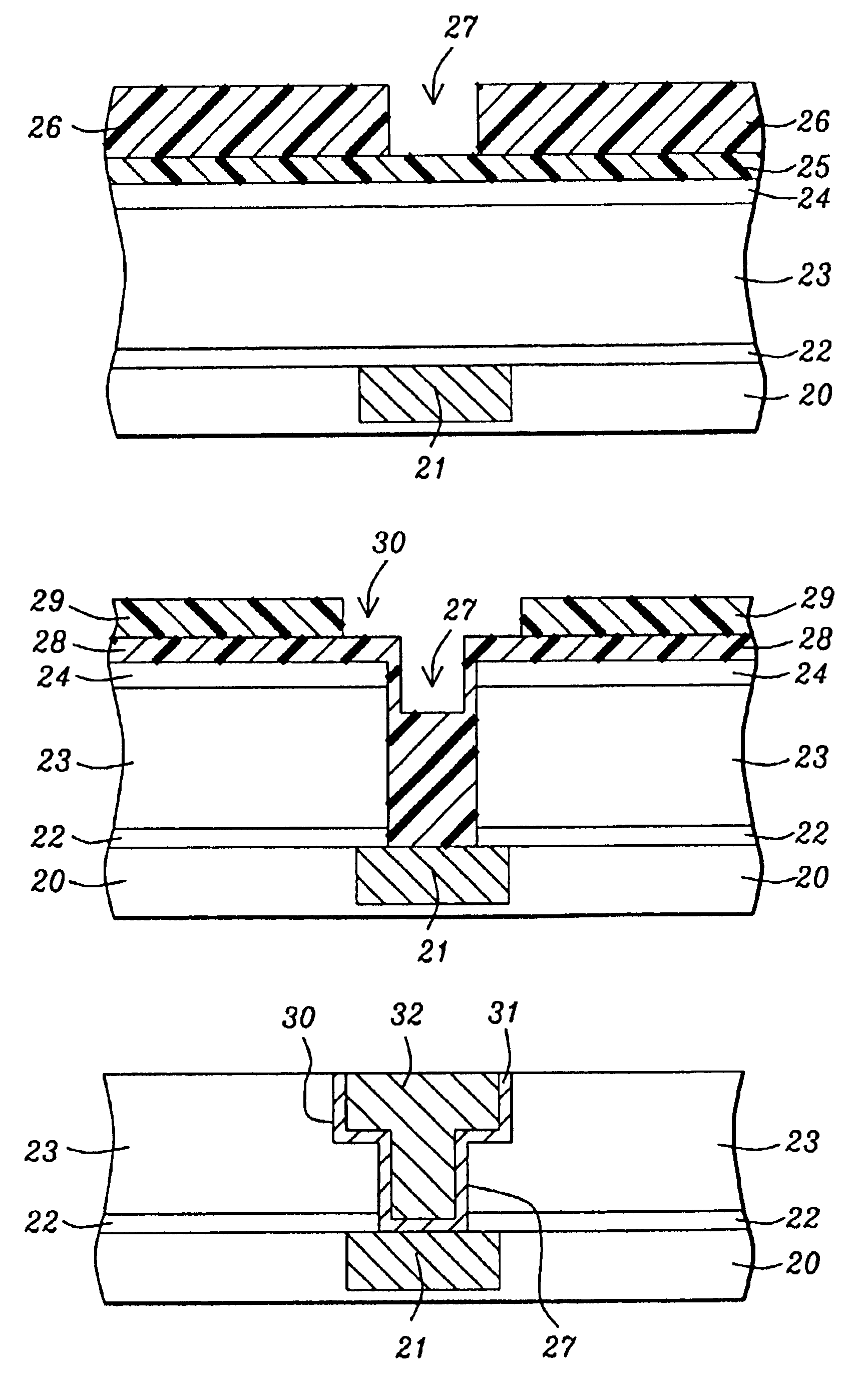

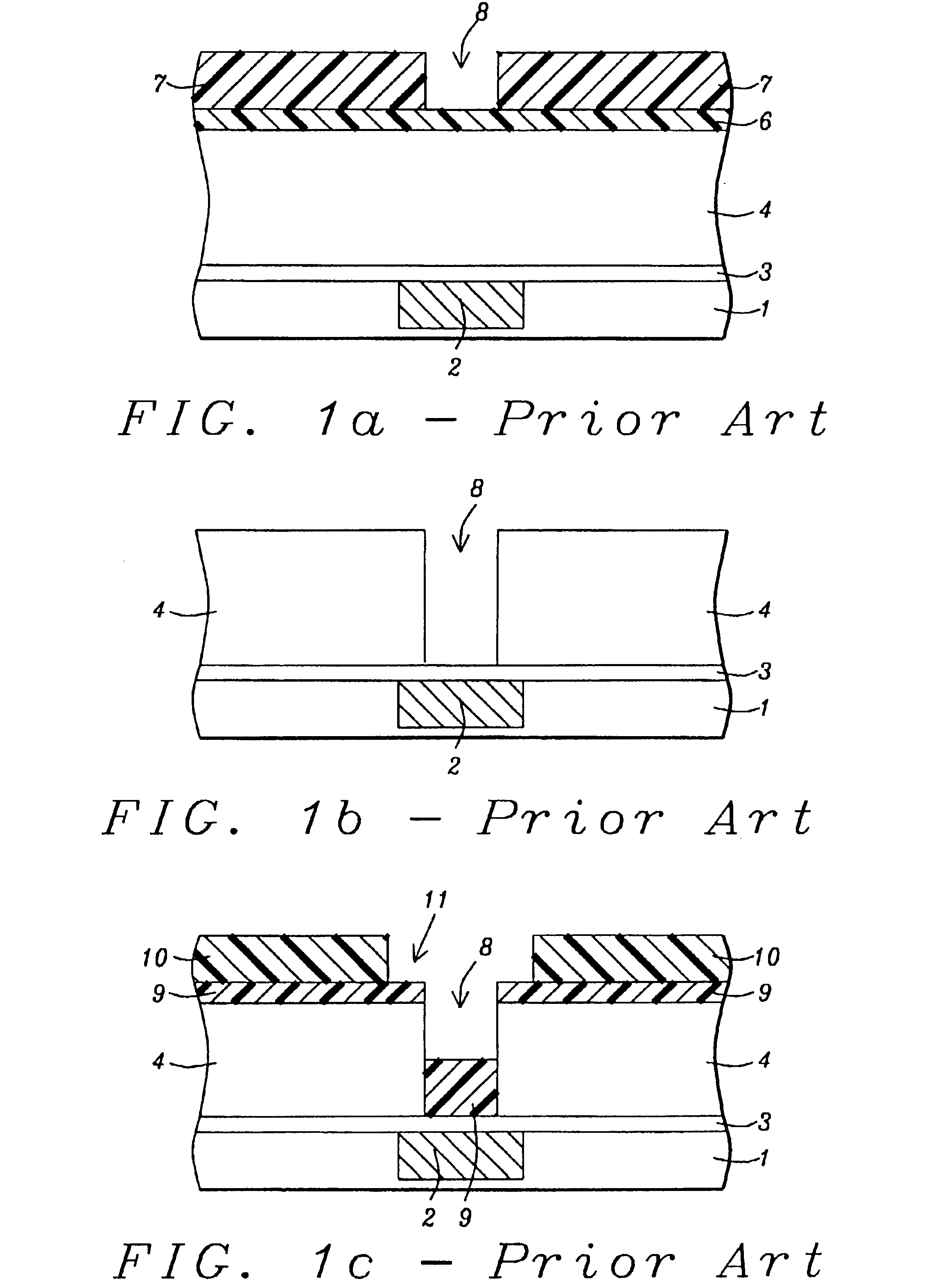

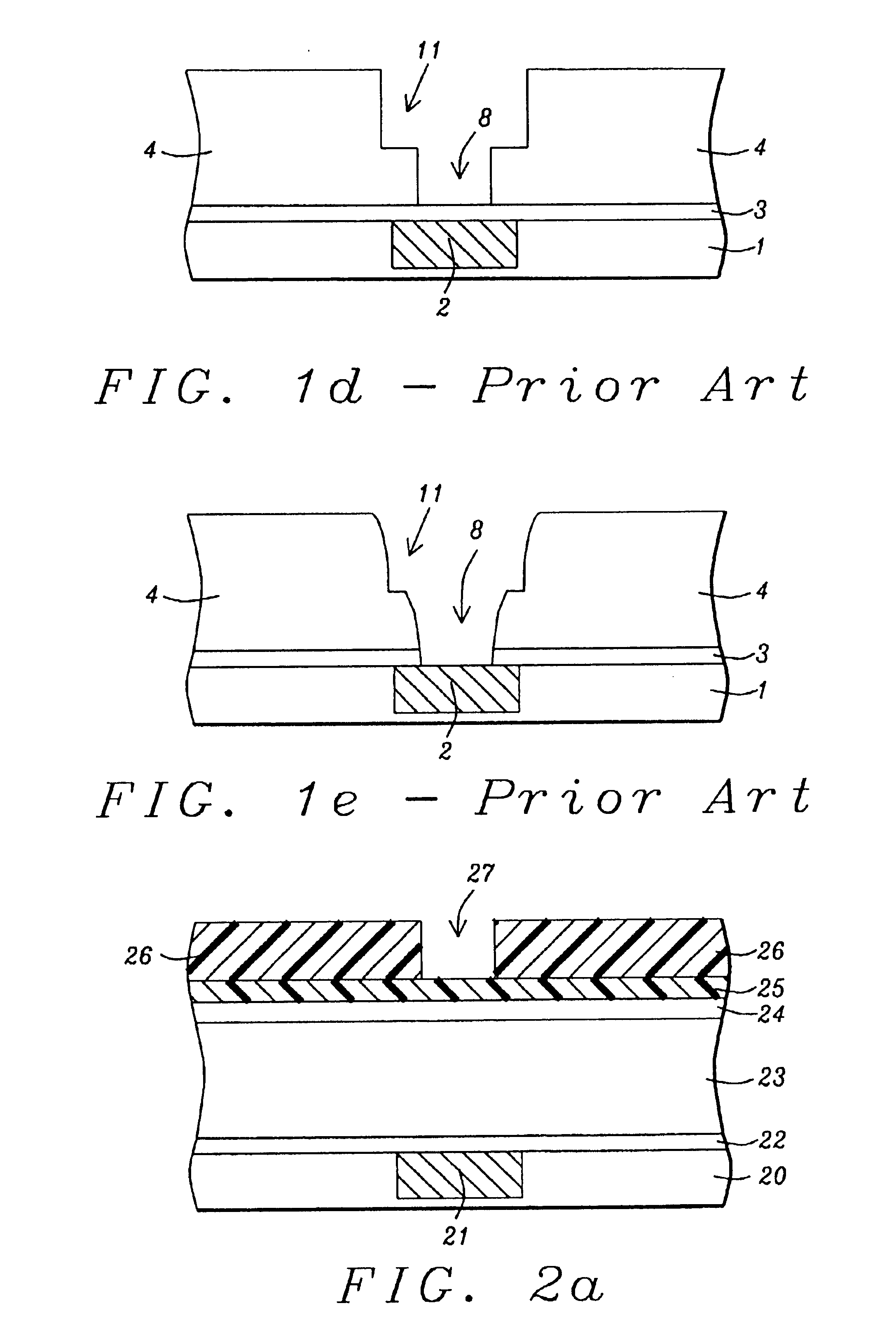

Method to form Cu/OSG dual damascene structure for high performance and reliable interconnects

InactiveUS6913994B2Not to damageEasy to controlSemiconductor/solid-state device manufacturingImproved methodDielectric layer

An improved method of forming a dual damascene structure that includes an organosilicate glass (OSG) dielectric layer is described. A via first process is followed in which a via is formed in the OSG layer and preferably stops on a SiC layer. The SiC layer is removed prior to stripping a photoresist containing the via pattern. A planarizing BARC layer is formed in the via to protect the exposed substrate from damage during trench formation. The method provides higher Kelvin via and via chain yields. Damage to the OSG layer at top corners of the via and trench is avoided. Furthermore, there is no pitting in the OSG layer at the trench bottom. Vertical sidewalls are achieved in the via and trench openings and via CD is maintained. The OSG loss during etching is minimized by removing the etch stop layer at an early stage of the dual damascene sequence.

Owner:AGENCY FOR SCI TECH & RES

Anti-dezincification free-cutting brass rod and production method thereof

The invention provides an anti-dezincification free-cutting brass rod being excellent in mechanical property, high in density and good in cutting property and a production method thereof. The brass rod comprises the following raw materials in percentage by mass: 60-66 of Cu, 0.1-06% of Bi, 0.1-0.5% of Sn, 0.02-0.07% of Fe, 0.2-0.8% of Al, less than 0.0038% of a modificator, 0.2-0.3% of Si, less than 0.15% of Ni, less than 0.15% of Pb, 0.08-0.18% of an As-Cu alloy, and the balance of Zn as well as impurities of which the total mass is less than 0.5%. The production method comprises the following steps: carrying out casting and extruding on a solid brass ingot; and extruding the treated brass ingot into the brass rod.

Owner:龙岩市鸿航金属科技有限公司

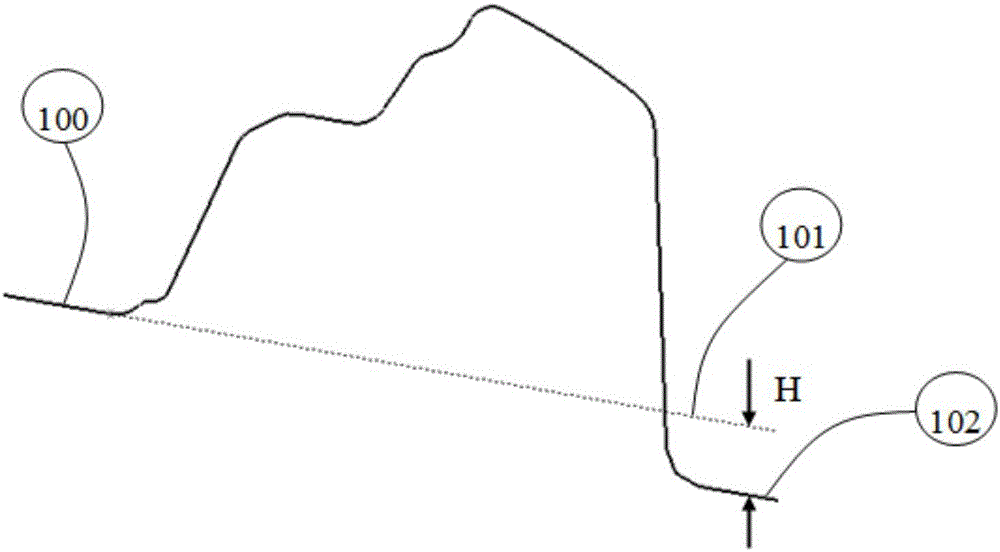

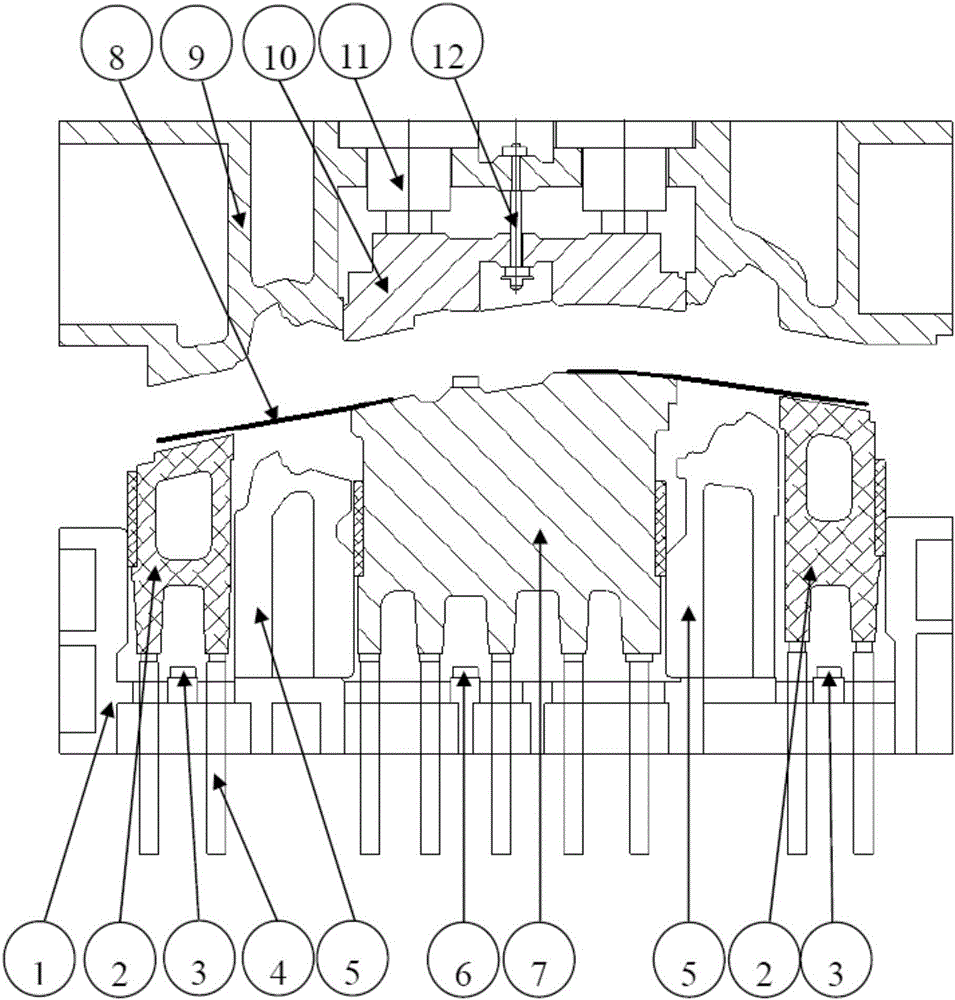

Vehicle body side outer plate drawing mold and drawing method

ActiveCN105945150AImprove drawing qualityEliminate depth gapsShaping toolsVehicle componentsMechanical engineeringEngineering

Owner:CHERY AUTOMOBILE CO LTD

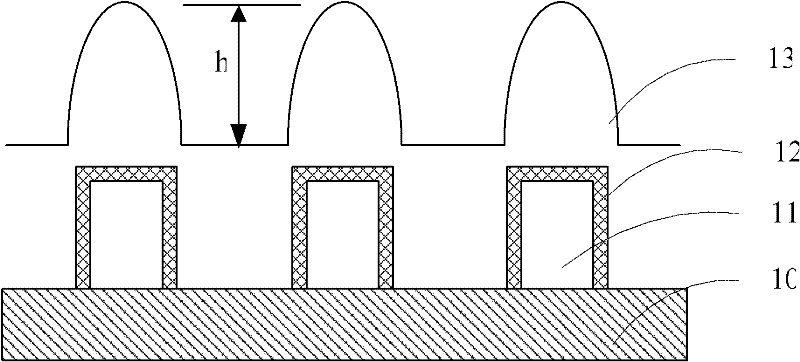

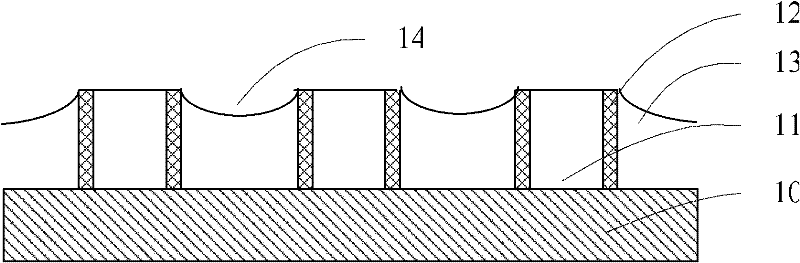

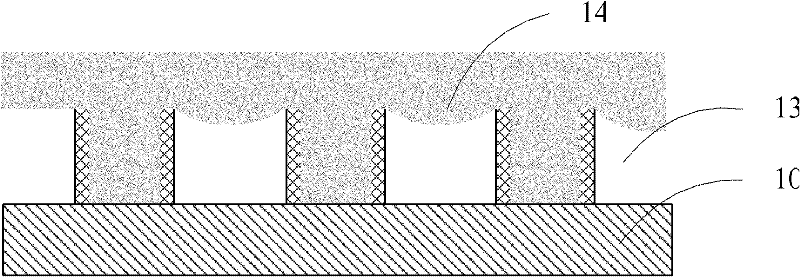

Chemical mechanical planarization method and manufacturing method of gate last

ActiveCN102479701APrevent short circuit defectsReduce or even eliminate potholesSemiconductor/solid-state device manufacturingSemiconductor devicesCompound (substance)Engineering

The invention provides a chemical mechanical planarization method and a manufacturing method of gate last. The chemical mechanical planarization method comprises the following steps: providing a substrate with a gate as well as a source region and a drain region at two sides of the gate, wherein an isolating layer is covered on the gate as well as the source region and the drain region of the gate, and the isolating layer comprises a convex part arranged above the gate and a concave part arranged on the surface of the substrate between gates; carrying out a selective doping process on the isolating layer and only enabling the convex part to be doped; and carrying out a CMP (Chemical Mechanical Polishing) process on the doped substrate, removing the convex part and planarizing the surface of the substrate. By using the method, the isolating layer is subjected to the selective doping process and only the convex part of the isolating layer is doped, so that the chemical corrosion action of grinding liquid in the CMP process to the material of the convex part can be enhanced, the removal rate of the material of the convex part in the CMP process is increased, the uniformity in a chip in a grinding process is improved, furthermore, no residual metal exists in the isolating layer between the gates in the forming process of the gate last, and a short circuit defect of a device can be avoided.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Manufacturing method for ultra-thin ferrite stainless steel belt with bright surface

ActiveCN107042235AEliminate cracksEliminate pittingRollsMetal rolling arrangementsMicrometerSurface roughness

The invention discloses a manufacturing method for an ultra-thin ferrite stainless steel belt with a bright surface. The ultra-thin ferrite stainless steel belt with the bright surface, the thickness being 0.05-0.1 mm, the surface gloss GS greater than or equal to 600 GU and the surface roughness Ra smaller than or equal to 0.02 micrometer is obtained through the processes of fine control working roller manufacturing, initial rolling, bright annealing, secondary rolling, bright annealing, finish rolling, bright annealing and leveling. According to the manufacturing method, a fine control working roller is adopted in the final pass of the finish rolling process, the surface roughness of the stainless steel belt is controlled in each process of the manufacturing process, the surface exquisiteness and the resolution of the ultra-thin ferrite stainless steel belt are greatly improved, and the surface roughness Ra of the ultra-thin ferrite stainless steel belt can be lowered to be smaller than 0.02 micrometer.

Owner:JIANGSU YONGJIN METAL TECHNOLOGY CO LTD

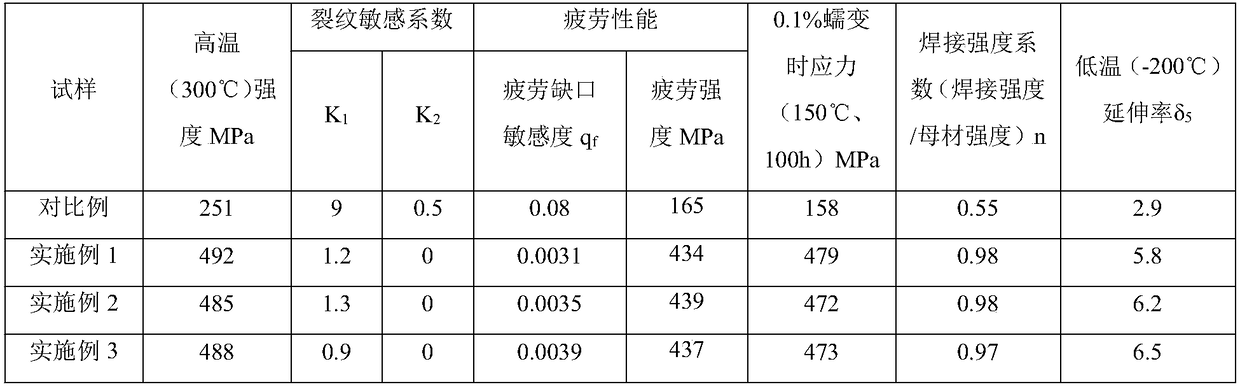

Aluminum alloy welding wire and manufacturing method thereof

ActiveCN108262576AReasonable alloy compositionEasy to organizeWelding/cutting media/materialsSoldering mediaNiobiumCerium

The invention relates to an aluminum alloy welding wire and a manufacturing method thereof. The aluminum alloy welding wire is prepared from the following elements in percentage by weight: 0.01 percent to 0.15 percent of iron, 0.01 percent to 0.12 percent of silicon, 0.01 percent to 0.1 percent of copper, 0 percent to 0.009 percent of scandium, 0.02 percent to 0.22 percent of manganese, 4.5 percent to 5.5 percent of magnesium, 0 percent to 0.009 percent of chromium, 0.01 percent to 0.18 percent of zinc, 0 percent to 0.003 percent of titanium, 0.001 percent to 0.03 percent of lithium, 0.001 percent to 0.01 percent of boron, 0 percent to 0.02 percent of vanadium, 0.005 percent to 0.009 percent of zirconium, 0.002 percent to 0.009 percent of cerium, 0.001 percent to 0.008 percent of yttrium,0.0001 percent to 0.002 percent of nickel, 0.0001 percent to 0.008 percent of strontium, 0.0001 percent to 0.009 percent of ytterbium, 0.0003 percent to 0.002 percent of neodymium, 0.0001 percent to 0.03 percent of niobium, and the balance aluminum. Compared with the prior art, according to the aluminum alloy welding wire and the manufacturing method thereof provided by the embodiment of the invention, the performance and the quality of the aluminum alloy welding wire can be remarkably improved, and the manufacturing cost of the aluminum alloy welding wire is comprehensively reduced.

Owner:江苏豪然新材料有限公司

A method for repairing shrinkage cavities in car topcoat

ActiveCN102284409ADoes not affect appearanceLower level requirementsPretreated surfacesSpecial surfacesVarnishRepair method

The invention relates to a method for repairing the finish paint defects of a car, in particular to a method for repairing a finish paint shrinkage cavity of the car, which comprises the steps that: a. the shrinkage cavity is cleaned; b. varnish is injected into and fully fills a concave hole of the shrinkage cavity; c. the shrinkage cavity is dried and cured; d. after a paint film is cured, the shrinkage cavity is ground by sandpaper; and e. the shrinkage cavity is polished. Because the scheme is adopted, pits of the shrinkage cavity are fully eliminated, the repaired shrinkage cavity appears the color of the original paint which is consistent with that of the paint of other parts due to the transparency of the varnish, so that color difference is avoided, the appearance effect of the finish paint is not affected, the repairing procedures are simpler, the requirement on the level of an operator is not high, manpower and material cost is saved, and the working efficiency is improved.

Owner:CHERY AUTOMOBILE CO LTD

Idle gear of heavy-duty engine and production method thereof

InactiveCN101526030AHigh hardnessImprove overall mechanical propertiesPortable liftingMachines/enginesHardnessHeavy duty

The invention provides an idle gear of a heavy-duty engine, production material of which is 38 CrMoAI. The production method of the idle gear is as follows: gear blank rough machining-hardening and tempering-gear blank fine machining-tooth shape machining-nitriding-pressing bushing-lathing bushing-rust prevention treatment. The hardening and tempering is carried out by changing the material so as to strengthen the hardness of the engine body and increase the synthesized mechanical property of the idle gear; the 38 CrMoAI material is fragile nitrided steel which has good strength, high hardness, and obvious increased wearing resistance; by the technique, tooth flank fatigue pitting and snaggletooth phenomenon are eliminated, thus increasing the wearing resistance and service life of the tooth flank and overall performance of the engine and meeting Europe IV emission and noise requirements.

Owner:湖北郧齿齿轮科技股份有限公司

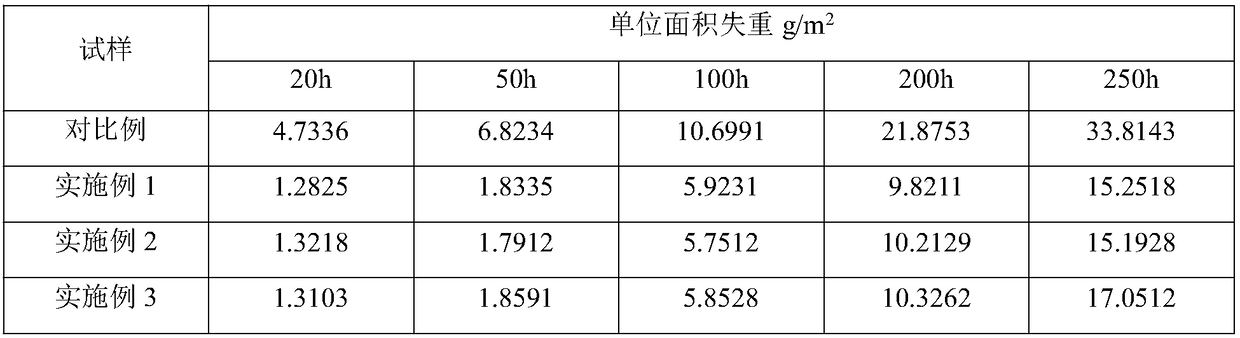

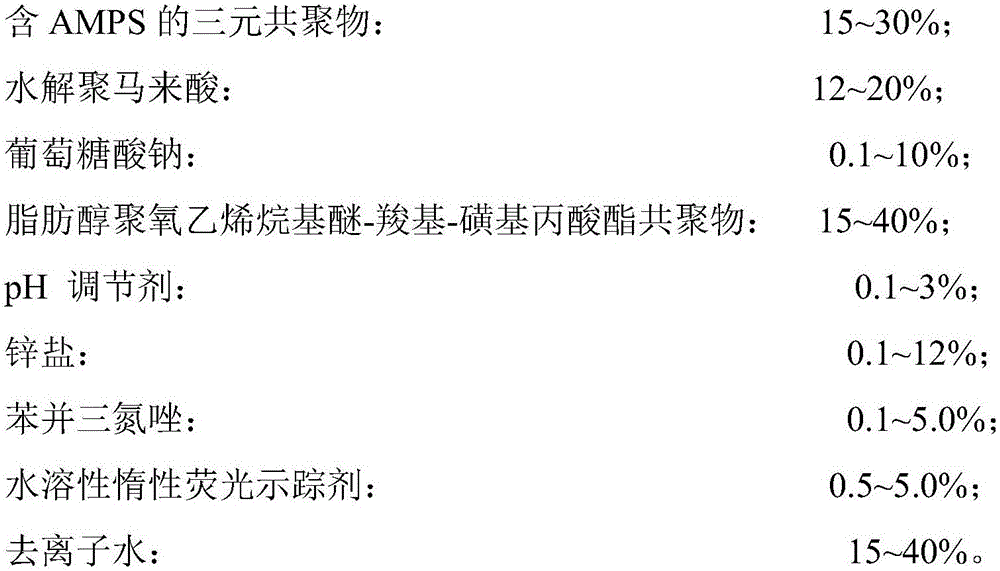

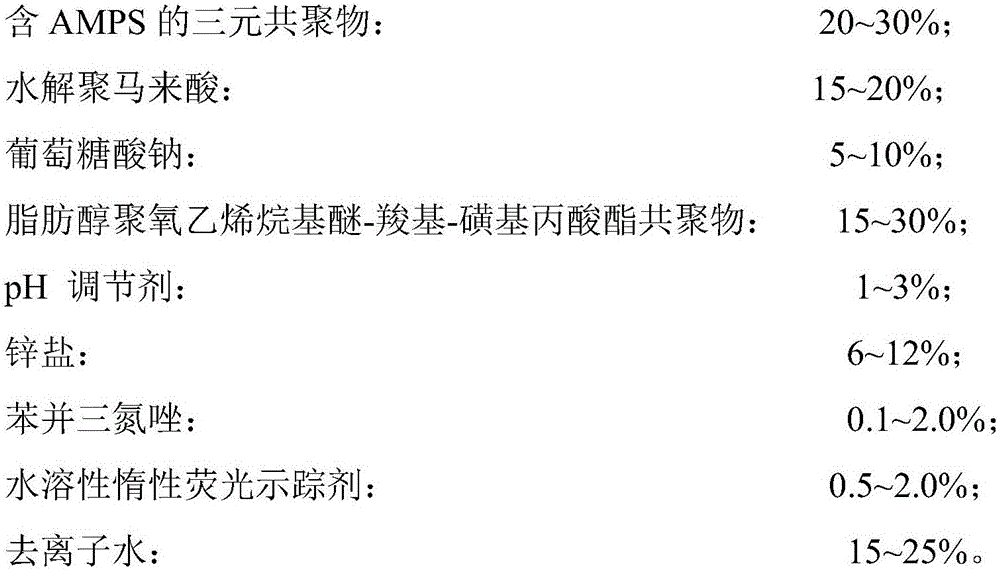

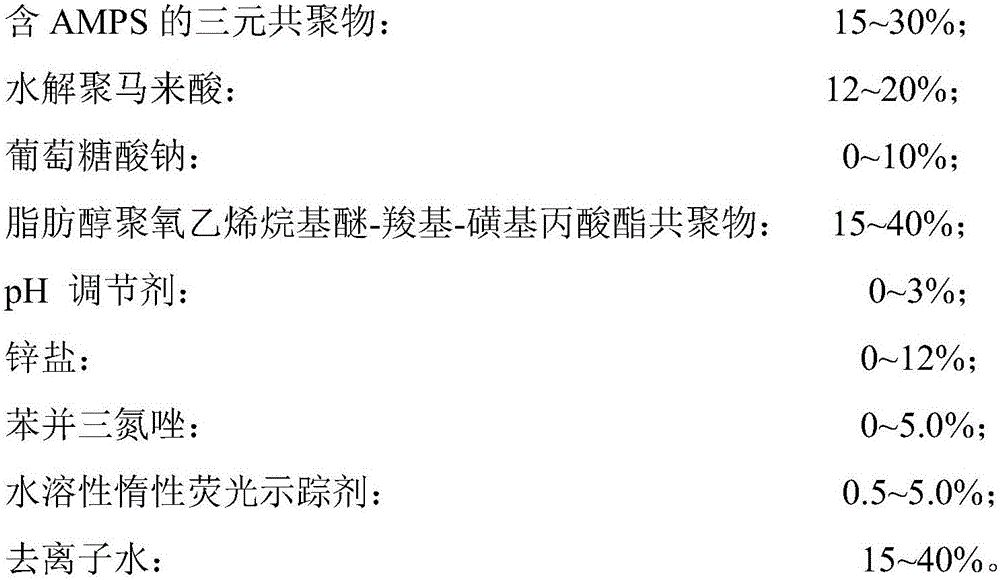

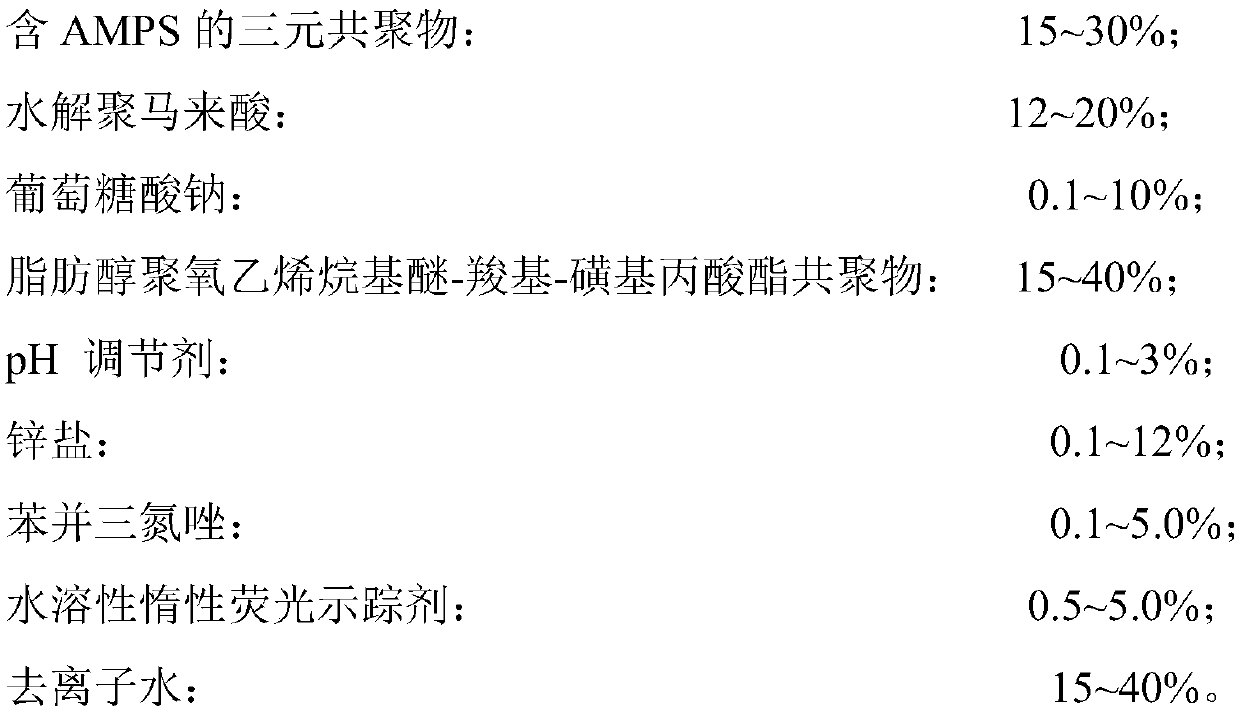

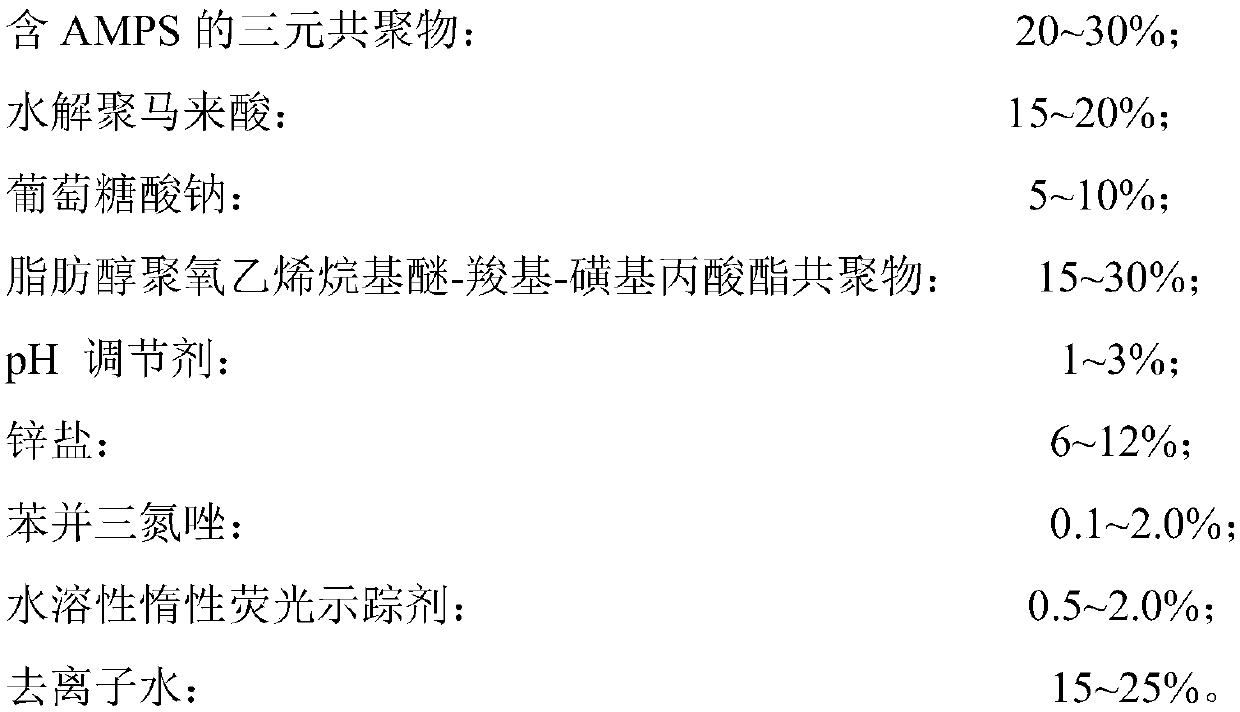

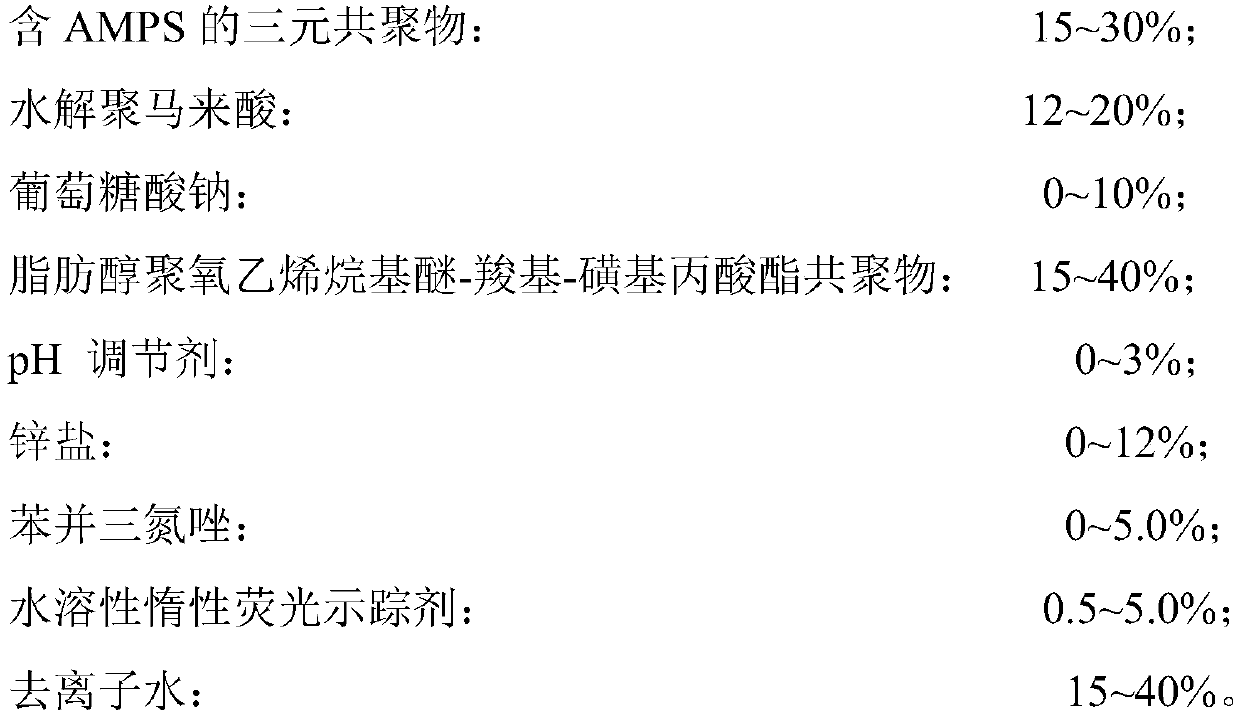

Non-phosphorus corrosion and scale inhibitor suitable for medium-and-low-hardness and strong-corrosion water and application of non-phosphorus corrosion and scale inhibitor

ActiveCN106082457AGood corrosion inhibitionGood synergySpecific water treatment objectivesTreatment using complexing/solubilising chemicalsWater qualityGluconic acid

The invention relates to a non-phosphorus corrosion and scale inhibitor suitable for medium-and-low-hardness and strong-corrosion water and application of the non-phosphorus corrosion and scale inhibitor. The non-phosphorus corrosion and scale inhibitor is prepared from the following ingredients by weight percent: 15-30% of an AMPS-containing terpolymer, 12-20% of hydrolyzed polymaleic acid, 0.1-10% of sodium gluconate, 15-40% of a fatty alcohol polyoxyalkylene alkyl ether-carboxyl-sulfopropionate copolymer, 0.1-3% of a pH regulator, 0.1-12% of zinc salt, 0.1-5.0% of benzotriazole, 0.5-5.0% of a water-soluble inert fluorescent tracer and 15-40% of deionized water. Compared with the prior art, the non-phosphorus corrosion and scale inhibitor provided by the invention solves the problem that a common non-phosphorus corrosion and scale inhibitor cannot draw the corrosion and scale inhibition function into consideration during concentration of a circulating water system. The non-phosphorus corrosion and scale inhibitor is favorable in performance and good in stability, has general applicability to medium-and-low-hardness and strong-corrosion water, and has the characteristics of no phosphorus, environmental friendliness and high efficiency.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

Molding method of curved glass

The invention provides a molding method of curved glass. The molding method comprises (1) preheating of a mold, (2) preheating of a flat glass plate, (3) hot press molding: putting the mold with the flat glass plate into a forming furnace and carrying out hot press molding, wherein the hot press molding comprises four stages: heating to 350-400 DEG C in the first state, heating to 580-600 DEG C inthe second stage, heating to 680-700 DEG C in the third state and heating to 750-770 DEG C in the fourth stage, (4) staged cooling: carrying out fast furnace cooling in three stages: cooling to 550-620 DEG C in the first stage, cooling to 350-400 DEG C in the second stage and cooling to the room temperature in air in the third stage, and (5) annealing: feeding curved glass into an annealing furnace, heating the curved glass to 200-240 DEG C, keeping the temperature and carrying out furnace cooling to the room temperature. The curved glass obtained by the molding method has a stable structure,high strength, high gloss of the glass surface, beautiful appearance, and no defects such as mold print and indentation.

Owner:安徽晶晶玻璃制品有限公司

Ultra-low temperature nitridation method for engine cylinder liner of large-scale watercraft

ActiveCN101492806AOvercoming the disadvantages of high temperature nitridingQuality assuranceSolid state diffusion coatingWatercraftPulp and paper industry

The invention discloses an ultra low temperature nitridizing method for a large ship engine cylinder sleeve, comprising the steps as follows: (1) towel is used to clean up the oil stain on a work piece; (2) the work piece is put into a clamping apparatus; (3) the work piece is put into a decontamination agent tank to carry out oil coating at the temperature of 75-95 DEG C for 5-8min; (4) the coated work piece is washed by running water; (5) the work piece is preheated at the temperature of 200-250 DEG C for 50-60min; (6) Na2SO4 with the weight of 8% is added into the nitridizing agent in the nitridizing furnace; the nitridizing temperature is 350 plus / minus 5 DEG C and the period is 2.5-3h; (7) the nitridized work piece is cooled in the air to below 150 DEG C; (8) the work piece is washed by running water; (9) the nitridized cylinder sleeve is checked; (10) the qualified cylinder sleeve is soaked into rust preventative oil; (11) the soaked cylinder sleeve is packaged and stored for transportation. The invention adopts low temperature nitrogen treatment, so that the nitridizing period is shortened, the production cost is lowered, and the product quality is improved, thus being suitable for industrialized mass production.

Owner:江苏华晨气缸套股份有限公司

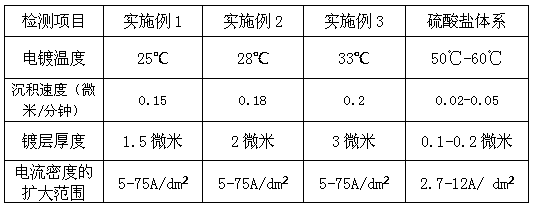

Sulphate trivalent chromium electroplating pollution as well as preparation process thereof and electroplating process thereof

The invention relates to a sulphate trivalent chromium electroplating pollution which comprises conductive salt, a preparation A, a preparation B, a preparation C, a preparation D, a wetting agent andpure water. At the normal temperature of 25-40 DEG C, an electroplated workpiece can be adopted to obtain a trivalent chromium coating with good appearance, and the thickness of the coating can be 1micron or more; the electroplated workpiece is strengthened in corrosion resistance, hardness, electrical conductivity, smoothness, heat resistance and wear resistance; a deposition rate of a chromiumlayer is 0.1-0.2 micron per minute; and electric energy can be saved, and use cost can be reduced in case of guaranteeing process quality. The Lab colour of the coating can be freely regulated withina range of L being greater than 65 and smaller than 80, a being greater than (-)1 and smaller than 1, and b being greater than 2 and smaller than 6, so that the colour of the coating can be regulatedto be brownish black from sliver, and the coating has the advantages of being good in stability, strong in covering power, good in uniform-coating ability and environmentally friendly.

Owner:陈建平

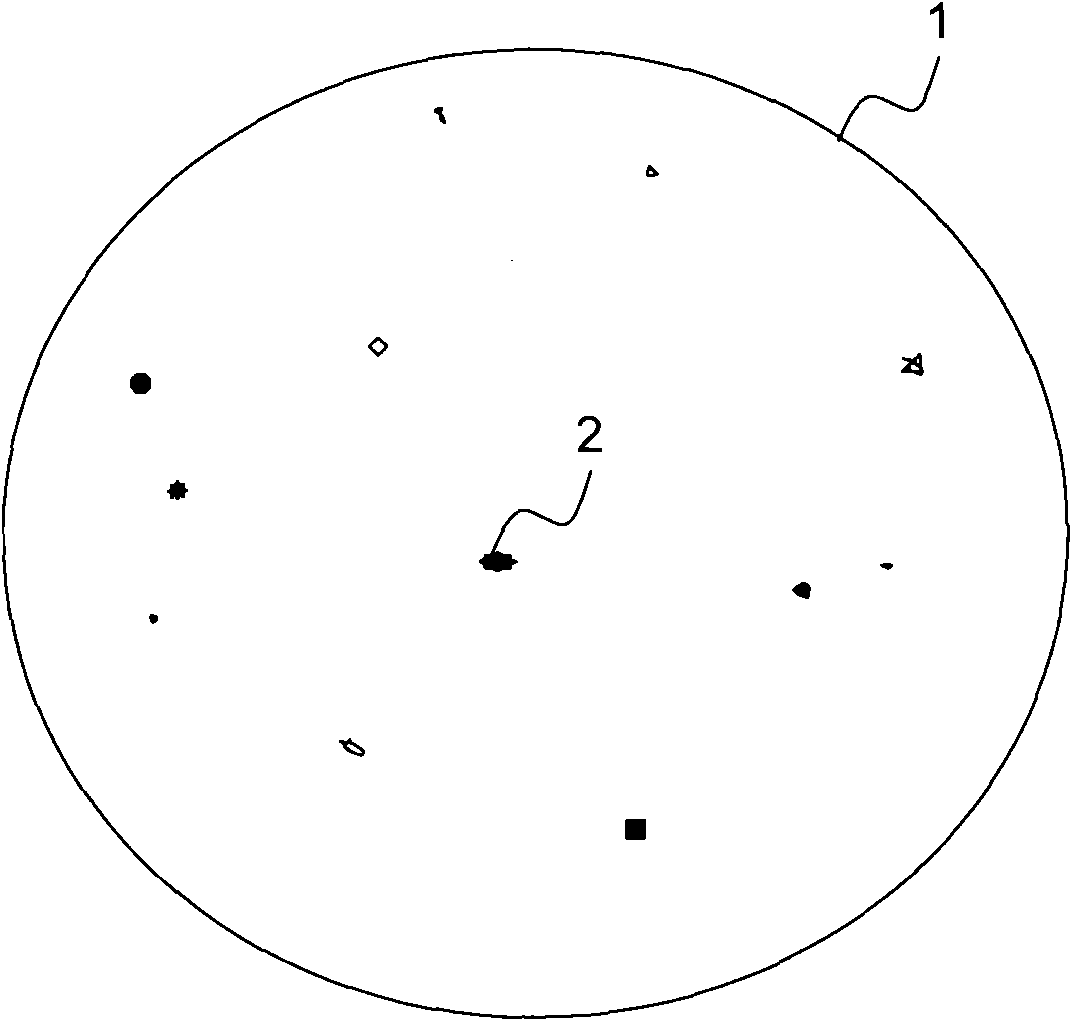

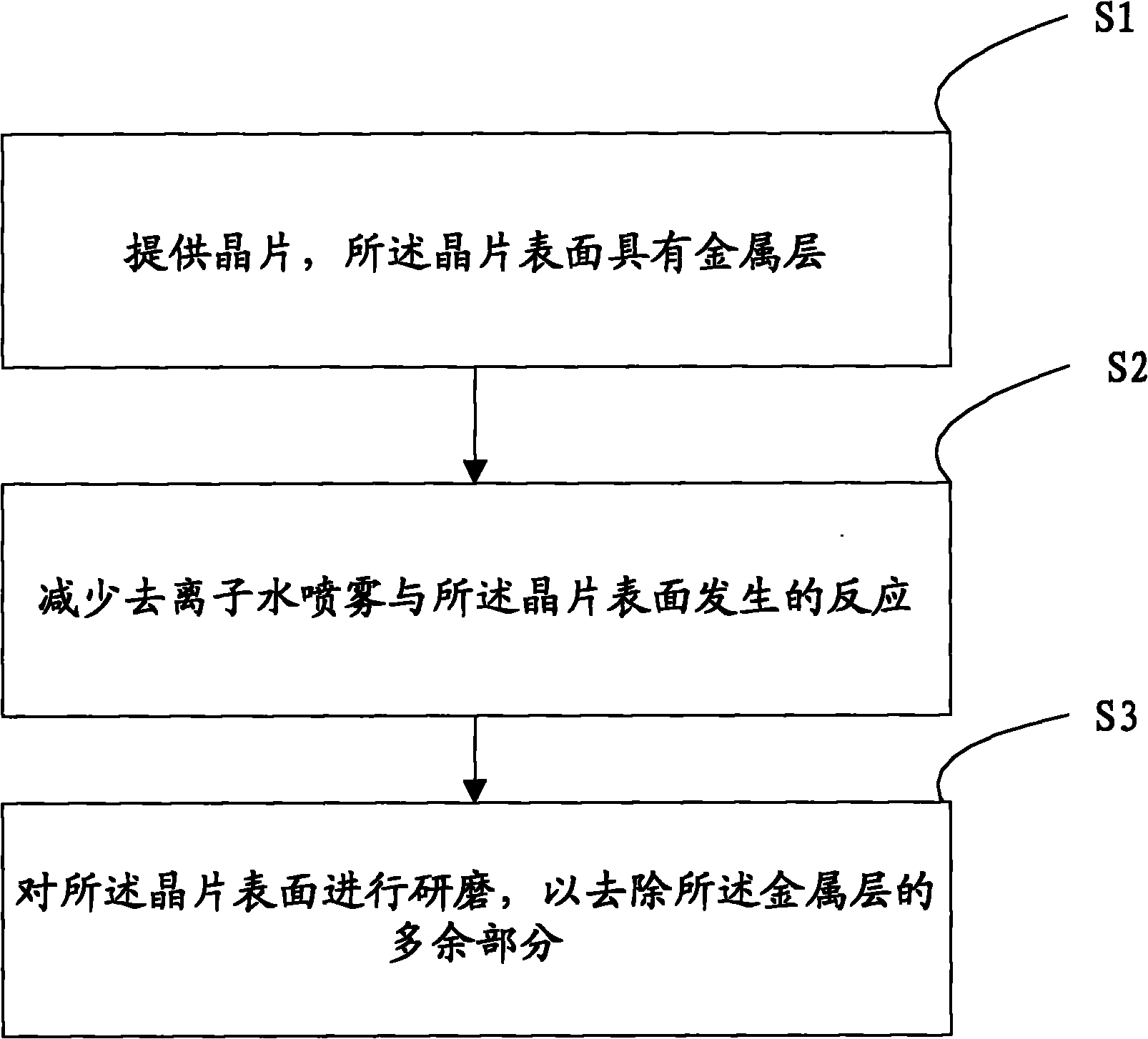

Method for chemical mechanical polishing and forming method of metal interconnection layer

InactiveCN102034738AEliminate pittingEliminate defects such as spotsSemiconductor/solid-state device manufacturingInterconnectionWater spray

The present invention provides a method for chemical mechanical polishing, comprising the steps of: supplying a wafer, wherein the wafer surface is provided with a metal layer; decreasing reactions between deionized water spray and the wafer surface; polishing the wafer surface to remove spare parts of the metal layer. Correspondingly, the present invention further provides a forming method of a metal interconnection layer. The step of decreasing reactions between deionized water spray and the wafer surface is performed before the wafer surface is polished, so that the method for chemical mechanical polishing and the forming method of metal interconnection layer can prevent the deionized water from contaminating on the metal layer of the wafer surface and prevent the deionized water from reacting with the metal layer to generate oxides; therefore, shortages of pits or spots at the wafer surface can be eliminated basically after the chemical mechanical polishing (CMP) process, and the reliability of integrated circuit is ensured.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Construction method of highway asphalt pavement

ActiveCN102011360AIncreased durabilityPrevent intrusionIn situ pavingsRoads maintainenceEngineeringRoad surface

The invention relates to a construction method of a highway asphalt pavement with long service life, which is suitable for ensuring highway quality. The construction method comprises the following steps: carrying out initial rolling by using a tyre roller: the tyre roller rolls 2-3 times after a spreading machine, and the temperature of the pavement is 120-150 DEG C in the rolling process; and finishing final rolling by using the steel roller. In order to prevent the material from attaching to the tyres, the temperature of the pavement is kept above 100 DEG C when the tyre roller is used for finishing initial rolling. Since the temperature of the pavement during initial rolling is high and the kneading amplitude of the tyres is high, the weight of the tyre roller can be properly reduced, and the design requirement for pavement compactness can be satisfied only by rolling 2-3 times. The rolling quality of the pavement is determined by temperature. Asphalt in the materials can easily form a thick seal oil film layer on the pavement, thereby preventing the invasion of water, mud and air, being beneficial to preventing the pavement from being damaged by water and enhancing the durability of the pavement.

Owner:宗焕清

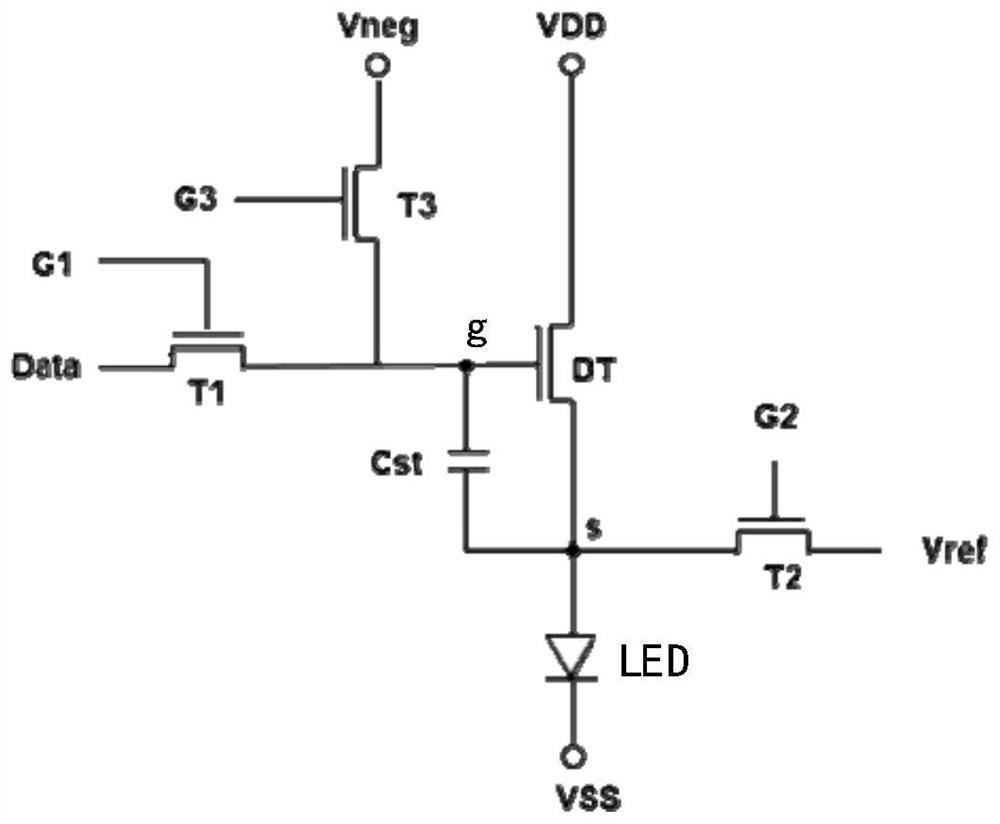

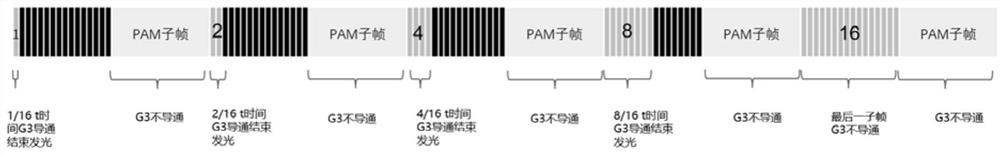

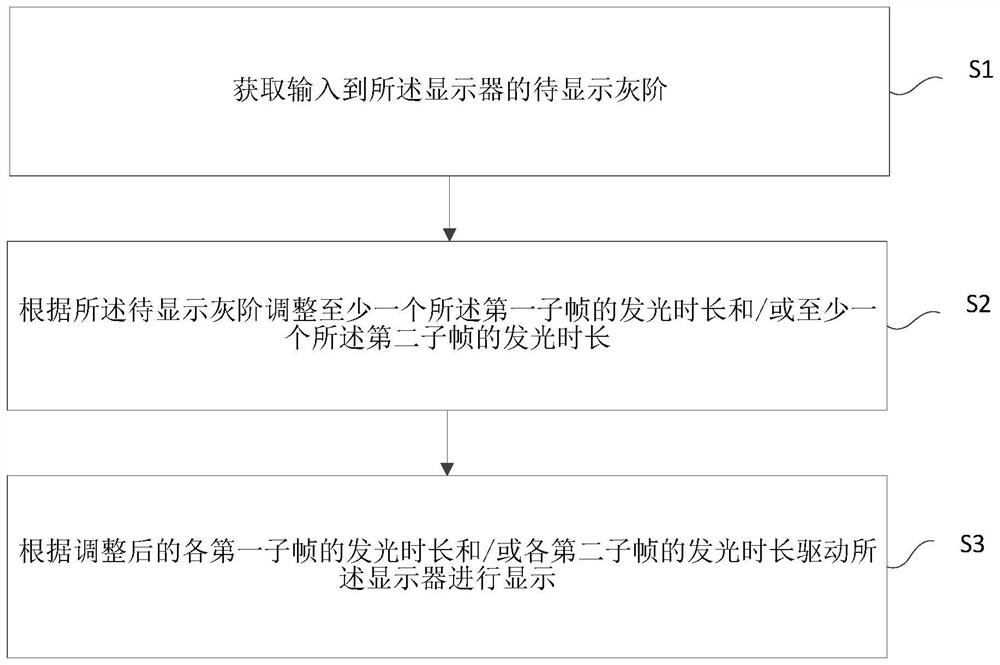

Hybrid driving method of display and hybrid driving module of display

PendingCN114664234AImprove the display effectImprove brightness uniformityStatic indicating devicesDisplay deviceGrey level

The invention relates to a hybrid driving method of a display and a hybrid driving module of the display. The method comprises the following steps: acquiring a to-be-displayed gray scale input to the display; adjusting the light-emitting duration of at least one first subframe and / or the light-emitting duration of at least one second subframe according to the gray scale to be displayed; and driving a display to display according to the adjusted light emitting duration of each first sub-frame and / or the adjusted light emitting duration of each second sub-frame. Hybrid driving is adopted, the to-be-displayed gray scale input to the display is obtained, then the light-emitting duration of at least one first sub-frame and / or the light-emitting duration of at least one second sub-frame is adjusted according to the to-be-displayed gray scale, and finally display is driven according to the adjusted light-emitting duration of each first sub-frame and / or the adjusted light-emitting duration of each second sub-frame. The brightness uniformity of different gray scales can be improved, the color cast phenomenon and the gray scale overturning phenomenon are further improved, meanwhile, the uniformity of a display picture is improved, the pocking mark phenomenon is eliminated, and the display effect of hybrid driving is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Powder coating for plastic lining, composite master batch and plastic lining composite pipe

ActiveCN111793413AFully dispersedImprove adhesionPowdery paintsPolyester coatingsMasterbatchPolymer science

The invention relates to a powder coating for plastic lining, a composite master batch and a plastic lining composite pipe. The powder coating for the plastic lining at least comprises resin, a fillerand an auxiliary agent, the resin comprises a resin base material and a resin proportioning material, the filler includes graphene, the graphene and the resin are proportioning material are prefabricated into a composite master batch, the composite master batch is added into the powder coating, the resin preferably selects carboxyl polyester resin, and the auxiliary agent preferably comprises a lubricant polyethylene wax. The preparation method comprises the following steps: mixing and dispersing graphene and the resin proportioning material, and crushing or granulating; or firstly dispersinggraphene into a lubricant, then mixing with the resin proportioning material, dispersing, and crushing or granulating to obtain a composite master batch; and then preparing the powder coating from the resin base material and other raw materials. By optimizing the components of the coating and optimizing the graphene adding process, on the basis of ensuring the optimal mechanical, chemical and thermal properties of a coating film, rapid proportioning is realized, the operation time is shortened, and a way is provided for the industrial application of graphene in the plastic-lined powder coating.

Owner:SHANDONG SHANGHE POWER TECH

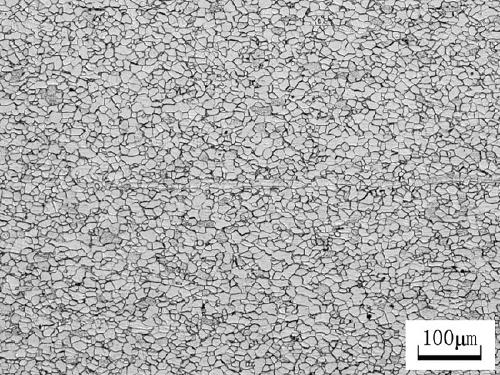

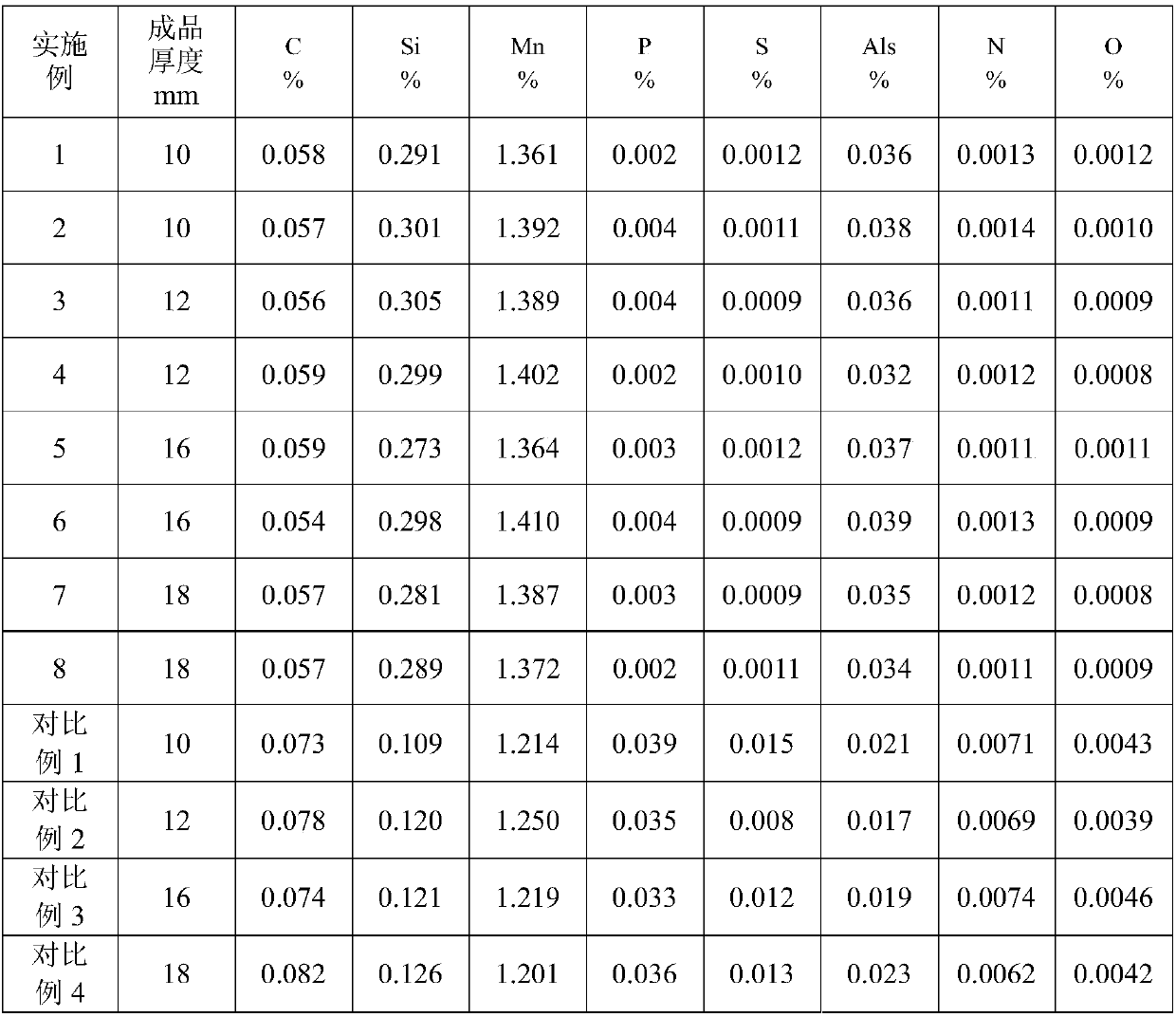

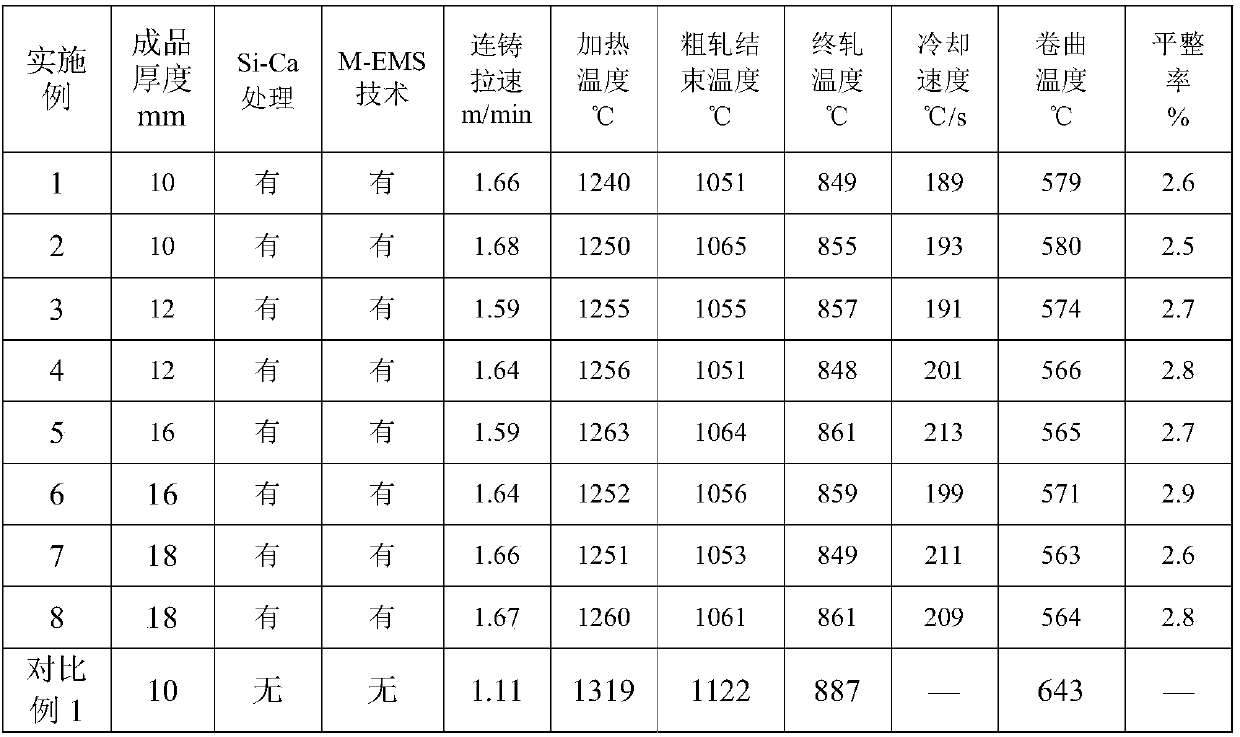

Wheel steel with excellent welding performance and production method

The invention provides wheel steel with excellent welding performance. Components of the wheel steel comprise, by weight percent, 0.031-0.061% of C, 0.250-0.350% of Si, 1.35-1.55% of Mn, smaller thanor equal to 0.005% of P, smaller than or equal to 0.0015% of S, smaller than or equal to 0.0015% of O, smaller than or equal to 0.0020% of N, 0.015-0.045% of Als, 0.010-0.020% of Nb. According to a production method, the steel enters an LF furnace to be refined after being smelted through a converter; RH vacuum treatment is carried out; continuous casting is carried out, and a casting blank is heated; rough rolling is carried out; high-pressure phosphorous removal is carried out two times continuously; first pass refining is carried out; high-pressure phosphorous removal is carried out; follow-up pass finish rolling is carried out; superfast cooling is carried out; rolling is carried out; and leveling is carried out. According to the wheel steel, it is ensured that the thickness of a product is 10-18 mm, the lower yield strength of the steel is 340-480 MPa, the tensile strength is 470-630 MPa, the ductility A80 is larger than or equal to 32%, after the material is subjected to flash butt welding, a transverse sample is 180 degree, the flexual center diameter d is equal to 0a to be qualified, pits on the surface of a steel plate can be eliminated, and thus the forming reject ratio after welding is reduced to one thousand percent and below.

Owner:武汉钢铁有限公司

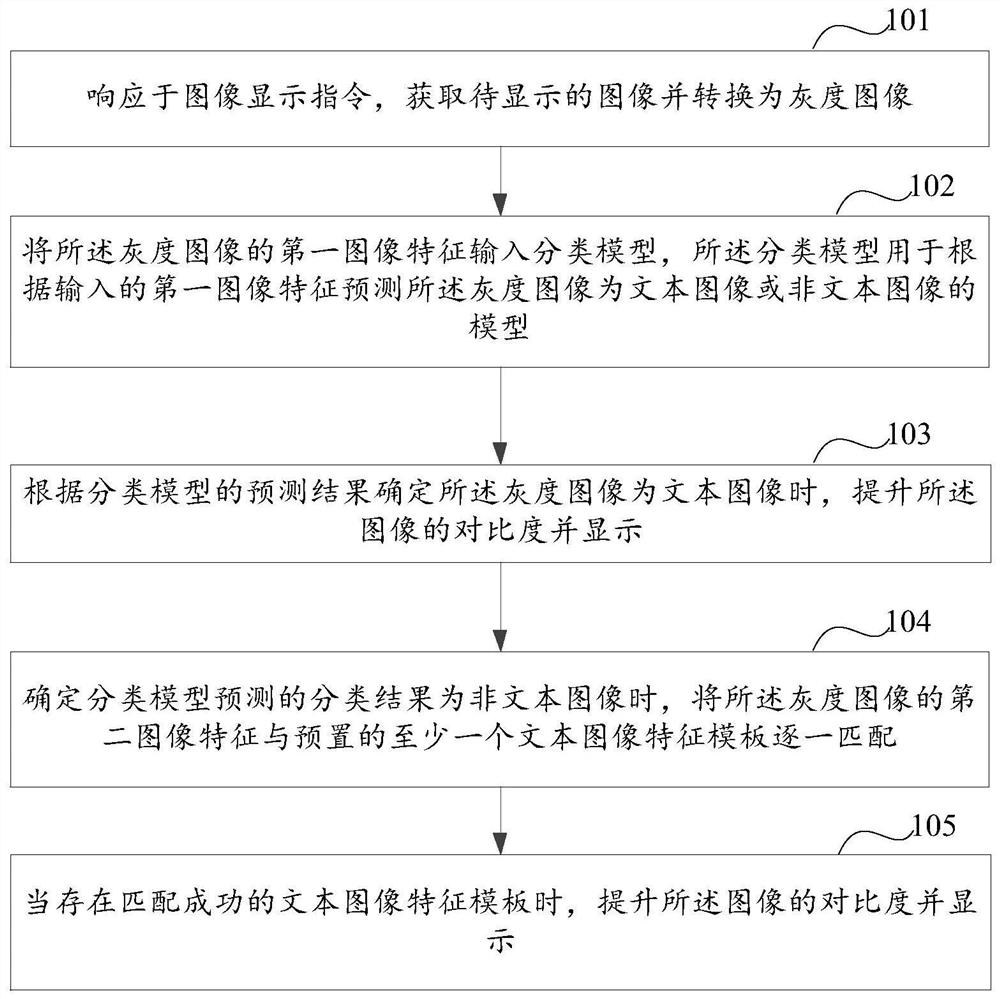

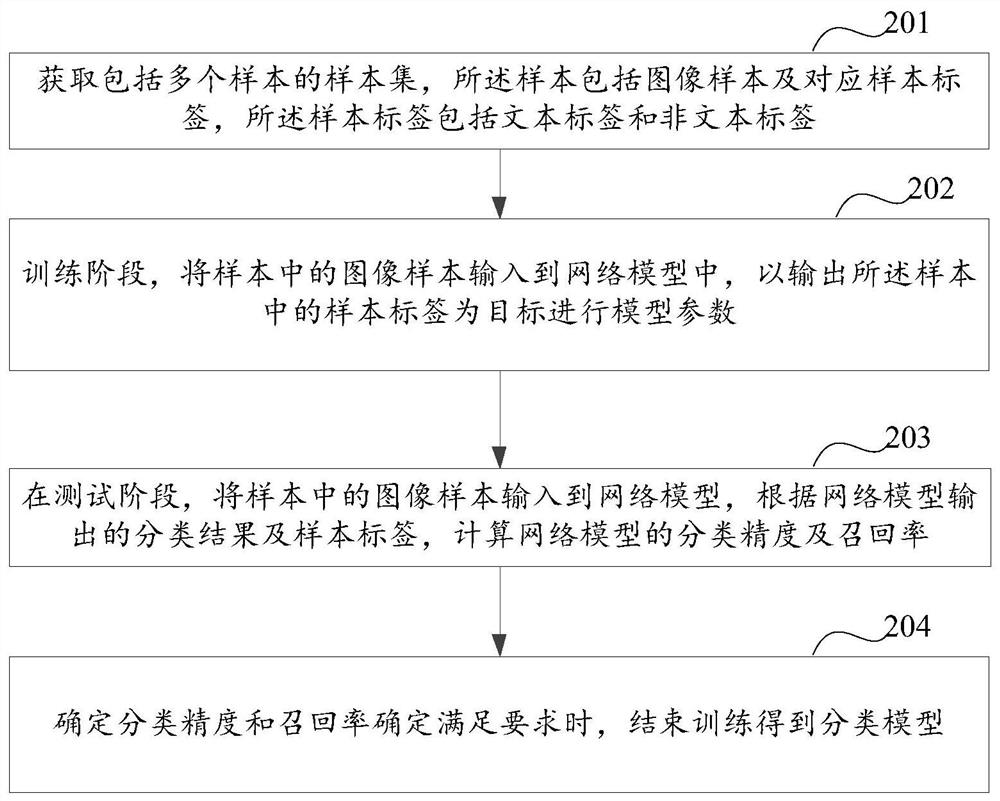

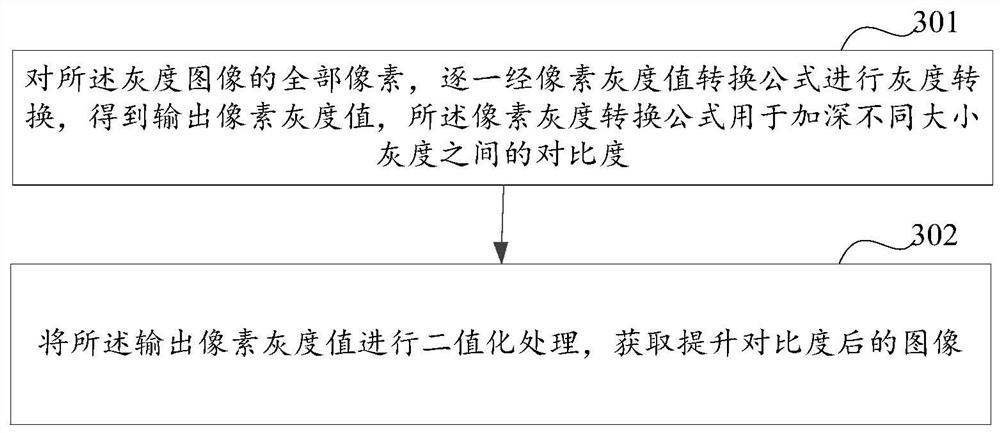

Image display method and device and electronic equipment

ActiveCN113408517AIncrease contrastAccurate identificationImage enhancementImage analysisRadiologyImaging Feature

The invention discloses an image display method and device and electronic equipment, and the method comprises the steps of obtaining a to-be-displayed image in response to an image display instruction, and converting the to-be-displayed image into a grayscale image; inputting the first image feature of the grayscale image into a classification model, wherein the classification model is used for predicting whether the grayscale image is a text image or a non-text image according to the input first image feature; when it is determined that the grayscale image is a text image according to the prediction result of the classification model, increasing the contrast ratio of the image and displaying same; when it is determined that a classification result predicted by the classification model is a non-text image, matching a second image feature of the grayscale image with at least one preset text image feature template one by one; and when the successfully matched text image feature template exists, improving the contrast ratio of the image and displaying the image. The text image can be identified more accurately, and pocking marks caused by a jitter point algorithm are eliminated.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

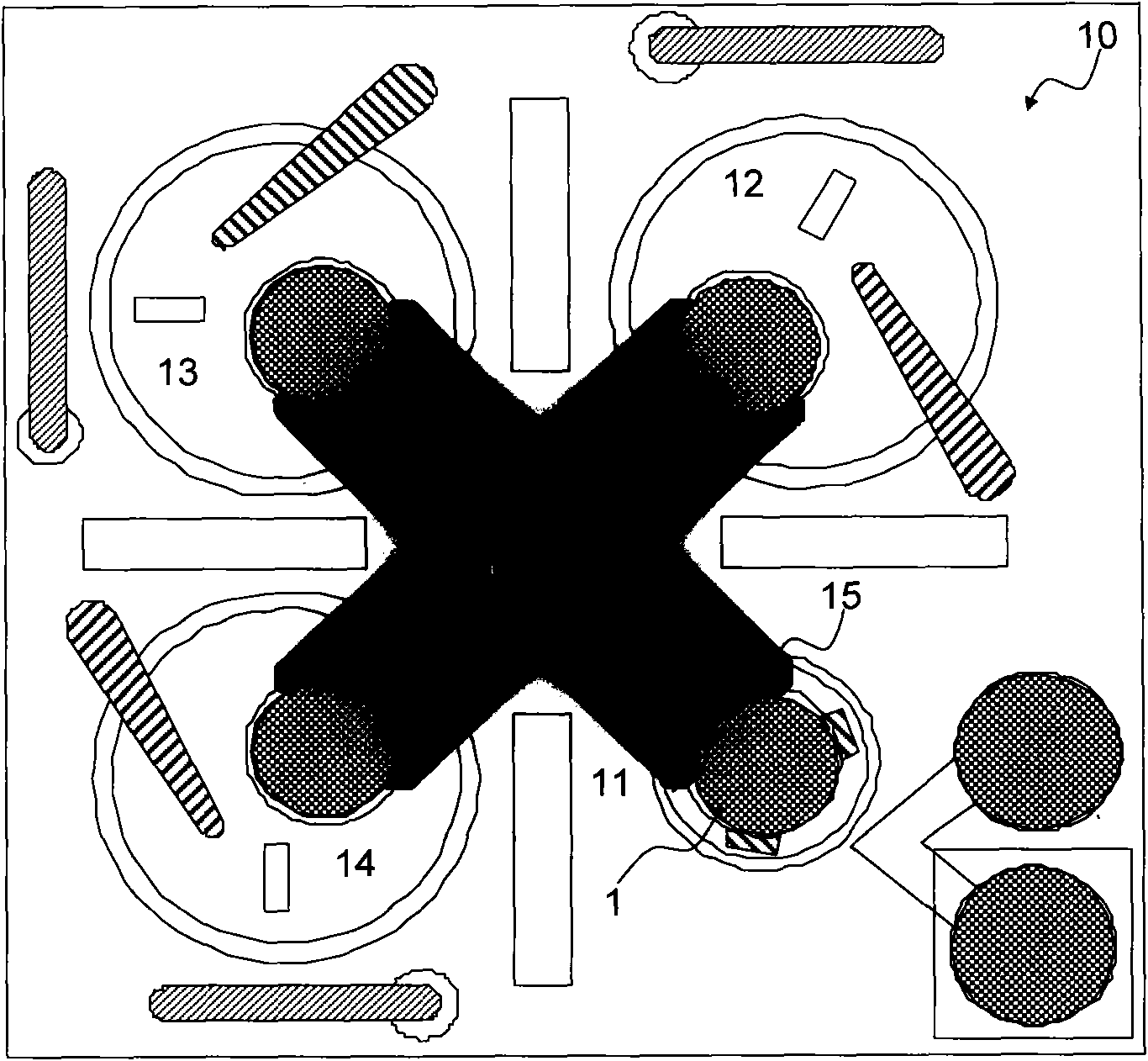

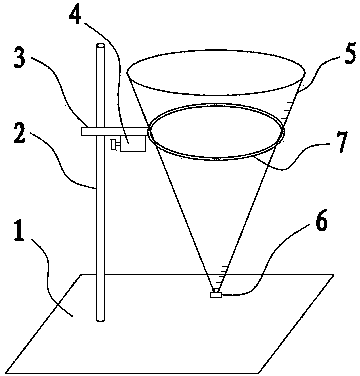

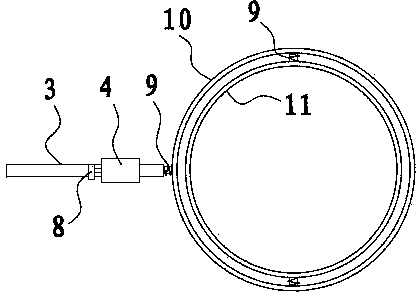

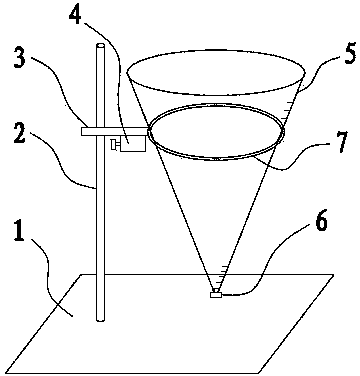

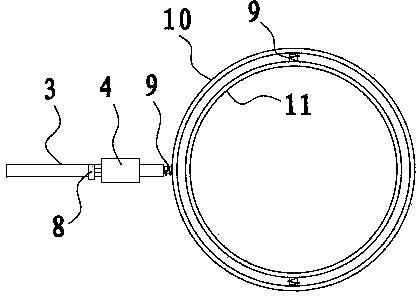

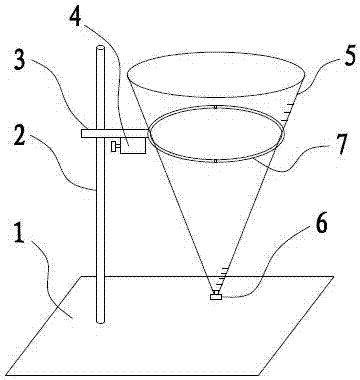

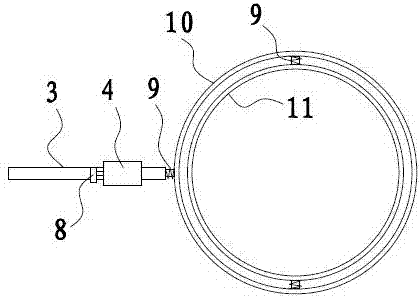

Phosphated residue content measuring device

InactiveCN104342695ARealize Quantitative MeasurementEasy to controlPhosphatisationElectrophoretic coatingsVisual inspectionMicro motor

The invention relates to a phosphated residue content measuring device, and solves the problems of inaccuracy and easy wrong judgment due to the judgment of phosphated liquid residue content by manual visual inspection experiences at present. The device comprises a bracket, wherein the bracket is provided with an annular bracket; a conical measuring cup with large top and small bottom is arranged on the annular bracket; scales for reading a pouring quantity of phosphated liquid are arranged on the side wall of the upper part of the conical measuring cup; scales for reading a height of precipitates are arranged on the side wall of the bottom of the conical measuring cup; and a detachable plug screw is additionally arranged at a conical top at the bottom of the conical measuring cup. The device realizes the quantization measurement of phosphated residues, and enables the control of the phosphated residues of the phosphated liquid to become more accurate; the measuring device adopts the self-adjustable bracket to guarantee the leveling between the upper surface of the precipitates and the scales for conveniently reading; and the measuring device owns a micro motor to provide high-frequency and low-amplitude vibration to eliminate pits in the upper surface of the precipitates so as to enable read numbers to become more accurate.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +2

Construction method for asphalt road surface of road

Owner:建发合诚工程咨询股份有限公司

A process of controlling phosphated residue content

ActiveCN104342696AAccurate readingEliminate pittingPhosphatisationElectrophoretic coatingsEngineeringConical measure

The invention relates to a process of controlling phosphated residue content, and solves the problems that a phosphated residue removing machine and regular trough inverting cannot adjust according to the actual situation of a phosphating solution, and currently, it is not accurate enough to estimate the residue content of the phosphating solution according to human visual experience so that it is easy to estimate wrongly. The process adopts a precipitation measuring device for auxiliary measurement. The precipitation measuring device comprises a support. The support is provided with a circular bracket. A conical measuring cup with a big end up is erected on the circular bracket. A scale for reading the pouring amount of the phosphating solution is provided on the side wall of the upper part of the conical measuring cup. A scale for reading the height of the precipitate is provided on the side wall of the bottom of the conical measuring cup. The cone top of the bottom of the conical measuring cup is further provided with a detachable plugging screw. 1000 ml phosphating solution is taken and poured into the conical measuring cup. After precipitating for 30-40 min, the precipitate content is read for judging whether the residue removing machine needs to be checked or the trough needs to be inverted. The process of the invention realizes quantification measurement of the phosphated residue to make the control for the phosphated residue of the phosphating solution more accurate. The reasonable design of the measuring device guarantees the accurate reading of the precipitate content.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +2

A kind of phosphating slag content control process

ActiveCN104342696BAccurate readingEliminate pittingPhosphatisationElectrophoretic coatingsSlagEngineering

The invention relates to a process of controlling phosphated residue content, and solves the problems that a phosphated residue removing machine and regular trough inverting cannot adjust according to the actual situation of a phosphating solution, and currently, it is not accurate enough to estimate the residue content of the phosphating solution according to human visual experience so that it is easy to estimate wrongly. The process adopts a precipitation measuring device for auxiliary measurement. The precipitation measuring device comprises a support. The support is provided with a circular bracket. A conical measuring cup with a big end up is erected on the circular bracket. A scale for reading the pouring amount of the phosphating solution is provided on the side wall of the upper part of the conical measuring cup. A scale for reading the height of the precipitate is provided on the side wall of the bottom of the conical measuring cup. The cone top of the bottom of the conical measuring cup is further provided with a detachable plugging screw. 1000 ml phosphating solution is taken and poured into the conical measuring cup. After precipitating for 30-40 min, the precipitate content is read for judging whether the residue removing machine needs to be checked or the trough needs to be inverted. The process of the invention realizes quantification measurement of the phosphated residue to make the control for the phosphated residue of the phosphating solution more accurate. The reasonable design of the measuring device guarantees the accurate reading of the precipitate content.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +2

Ultra-low temperature nitridation method for engine cylinder liner of large-scale watercraft

ActiveCN101492806BQuality assuranceGuaranteed not to deformSolid state diffusion coatingPulp and paper industryWatercraft

Owner:江苏华晨气缸套股份有限公司

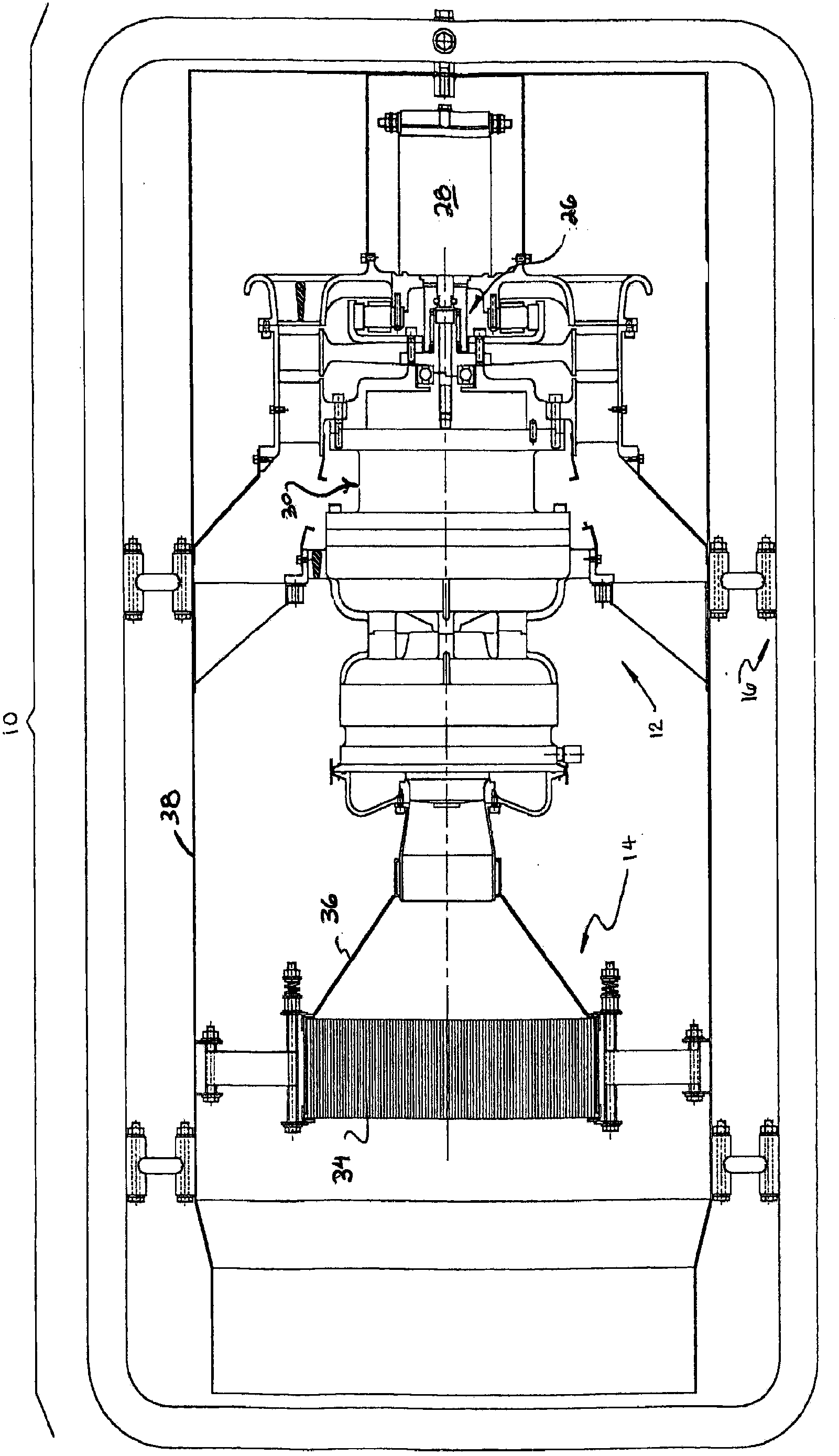

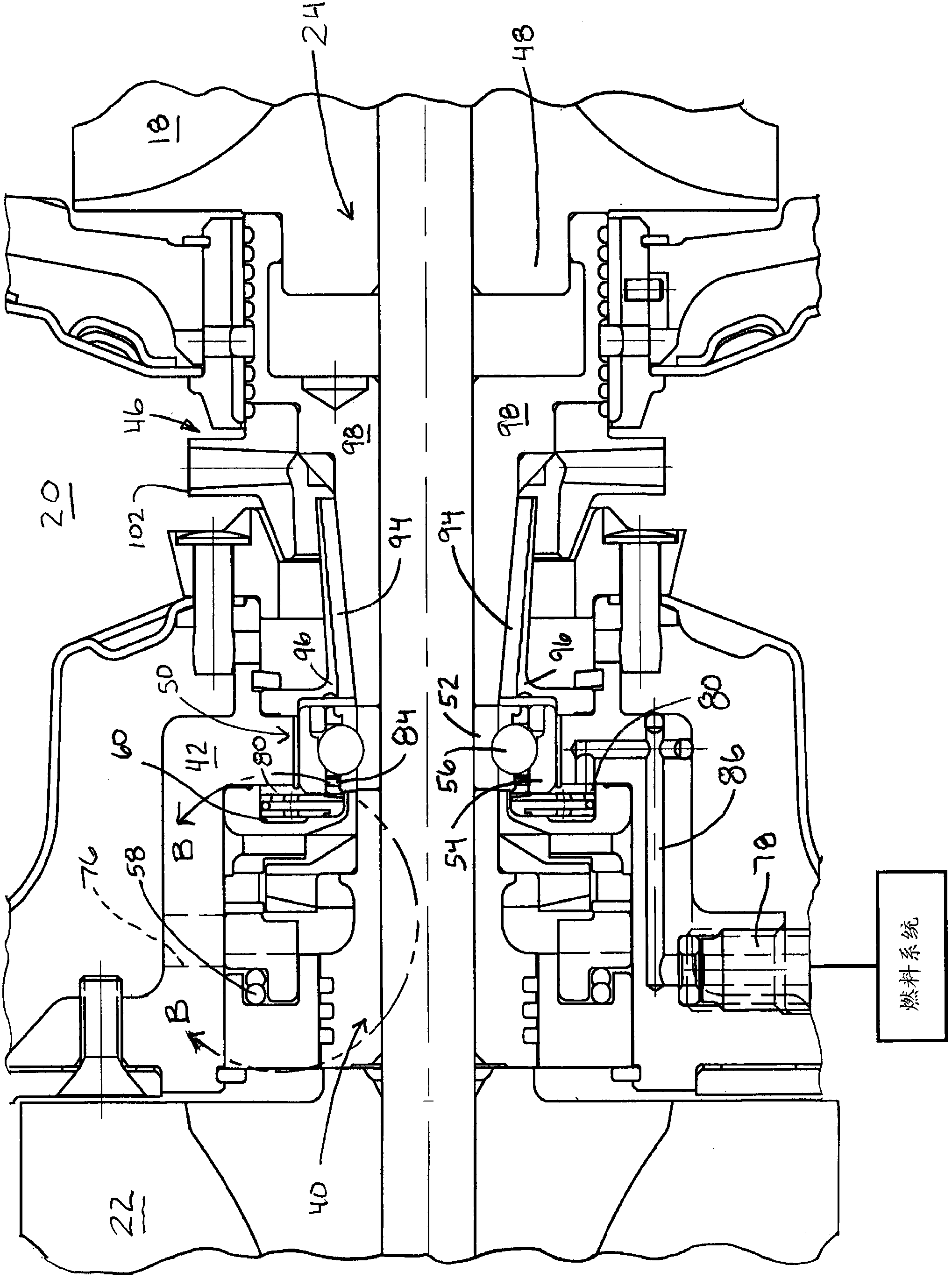

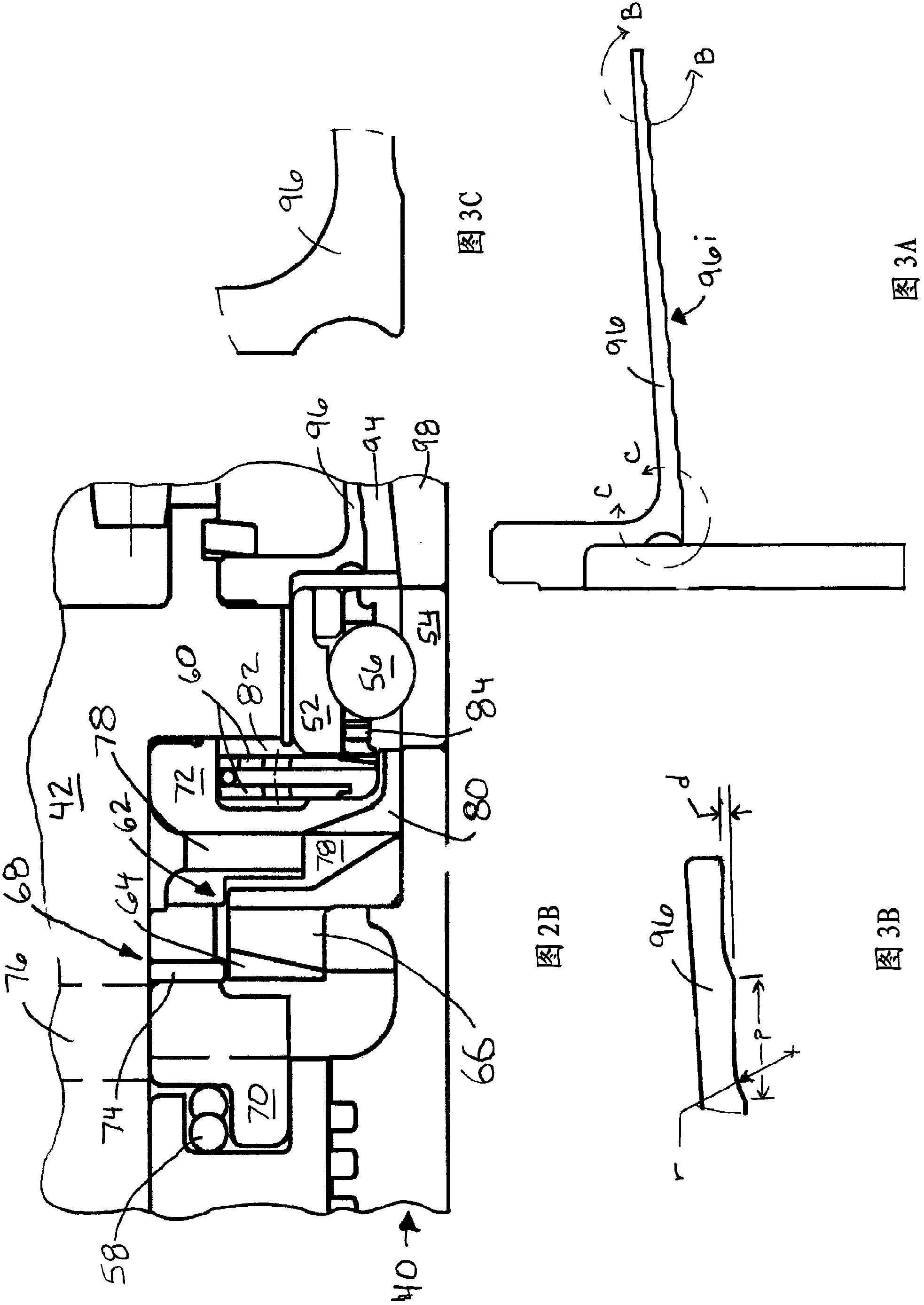

Micro-turbine combustor

InactiveCN102725497ARetrace lessEliminate pittingTurbine/propulsion fuel supply systemsEngine manufactureImpellerCombustion chamber

A micro gas turbine engine for use in a turbo heater or co-generation application is described. The micro gas turbine engine includes a fuel delivery system which minimizes the development of deposits in the air-fuel passageway. To this end, a fuel delivery channel formed between a fuel deflector and a slinger body is formed with a contoured or undulating surface. A fuel deflector ring is interposed between the fuel delivery channel and the slinger impeller to facilitate the flow of the air-fuel mixture into the combustion chamber.

Owner:JHRG公司

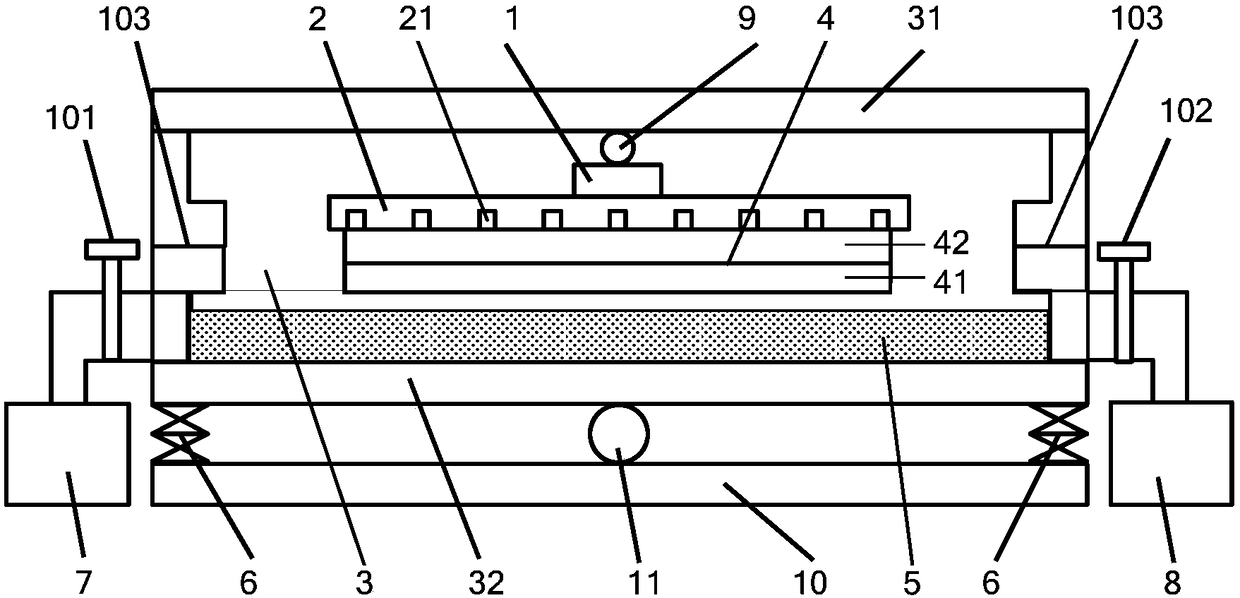

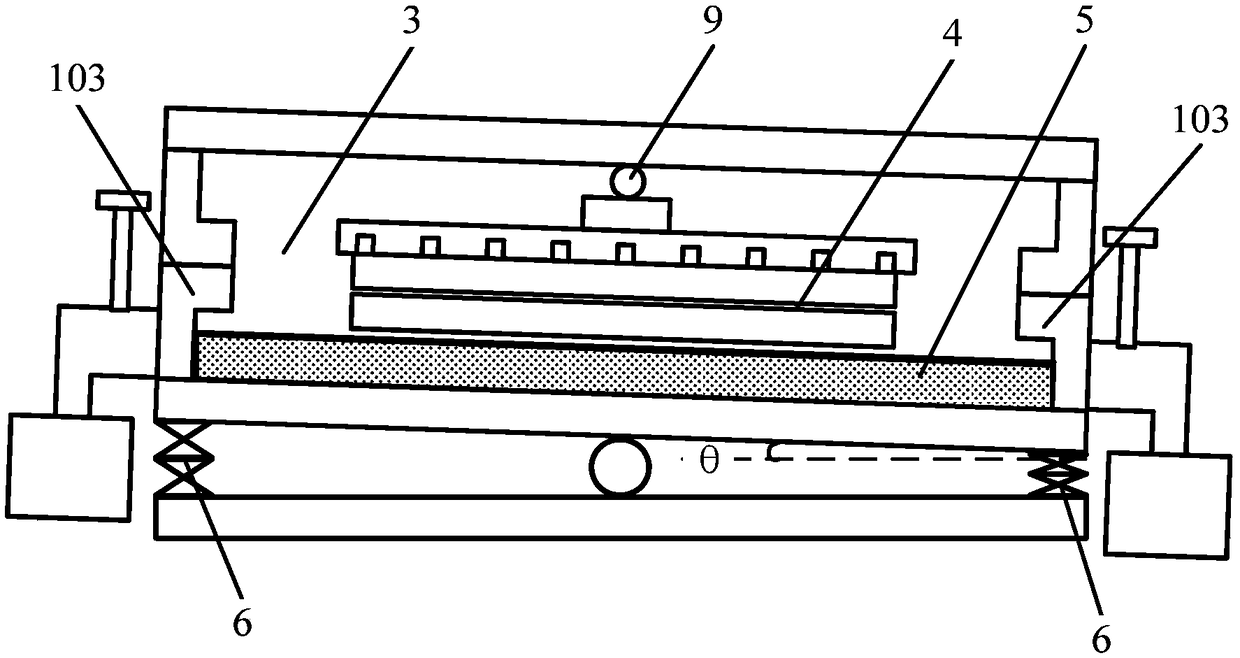

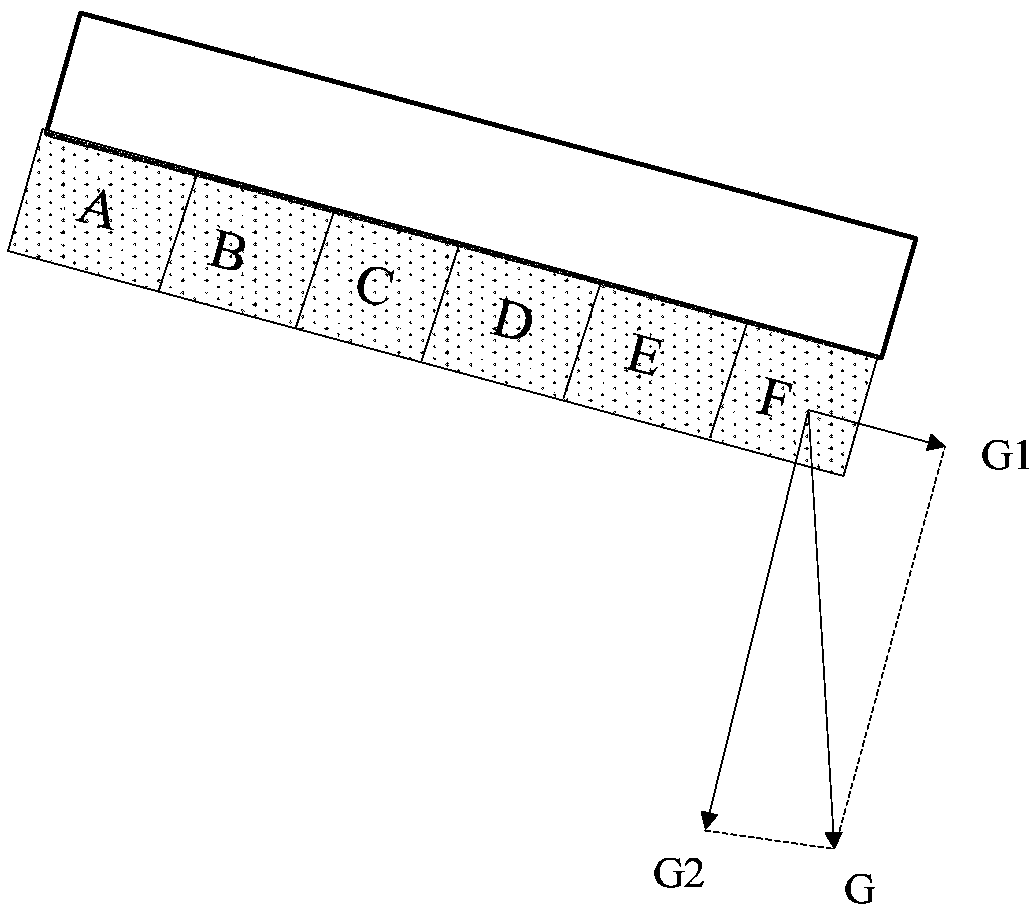

Thinning device and thinning method

ActiveCN108227257AAvoid defect amplificationEliminate pitsNon-linear opticsThinningElectrical and Electronics engineering

The invention provides a thinning device and a thinning method. A carrying device is utilized to fix a display panel, a height adjusting device is utilized to adjust a distance between the display panel and etching liquid in a liquid bin, and a first substrate is thinned step by step by enabling the first substrate of the display panel to contact with the etching liquid; preliminary thinning is realized at a first thinning stage, quick thinning is realized at a second thinning stage, slight thinning is realized at a third thinning stage, in this way, defects on the first substrate are not completely etched by the etching liquid too early, so that defect amplifying is avoided; correspondingly, defects like concave points and scratches on the surface of the display panel can be eliminated without through an extra polishing process, so that the thinning process of the display panel is simplified, the problem of chippings caused by the polishing process can be avoided, product yield is increased, and display effect is improved.

Owner:BOE TECH GRP CO LTD +1

Phosphorus-free corrosion and scale inhibitors suitable for medium-low hardness and strong corrosive water quality and its application

ActiveCN106082457BGood corrosion inhibitionGood synergySpecific water treatment objectivesTreatment using complexing/solubilising chemicalsEnvironmental resistanceWater quality

The invention relates to a non-phosphorus corrosion and scale inhibitor suitable for medium-and-low-hardness and strong-corrosion water and application of the non-phosphorus corrosion and scale inhibitor. The non-phosphorus corrosion and scale inhibitor is prepared from the following ingredients by weight percent: 15-30% of an AMPS-containing terpolymer, 12-20% of hydrolyzed polymaleic acid, 0.1-10% of sodium gluconate, 15-40% of a fatty alcohol polyoxyalkylene alkyl ether-carboxyl-sulfopropionate copolymer, 0.1-3% of a pH regulator, 0.1-12% of zinc salt, 0.1-5.0% of benzotriazole, 0.5-5.0% of a water-soluble inert fluorescent tracer and 15-40% of deionized water. Compared with the prior art, the non-phosphorus corrosion and scale inhibitor provided by the invention solves the problem that a common non-phosphorus corrosion and scale inhibitor cannot draw the corrosion and scale inhibition function into consideration during concentration of a circulating water system. The non-phosphorus corrosion and scale inhibitor is favorable in performance and good in stability, has general applicability to medium-and-low-hardness and strong-corrosion water, and has the characteristics of no phosphorus, environmental friendliness and high efficiency.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

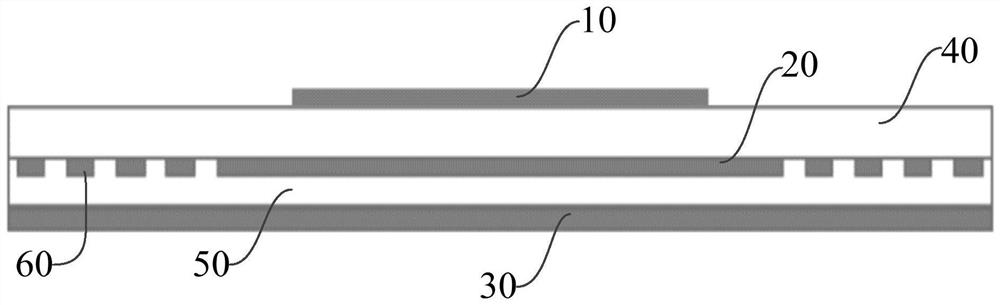

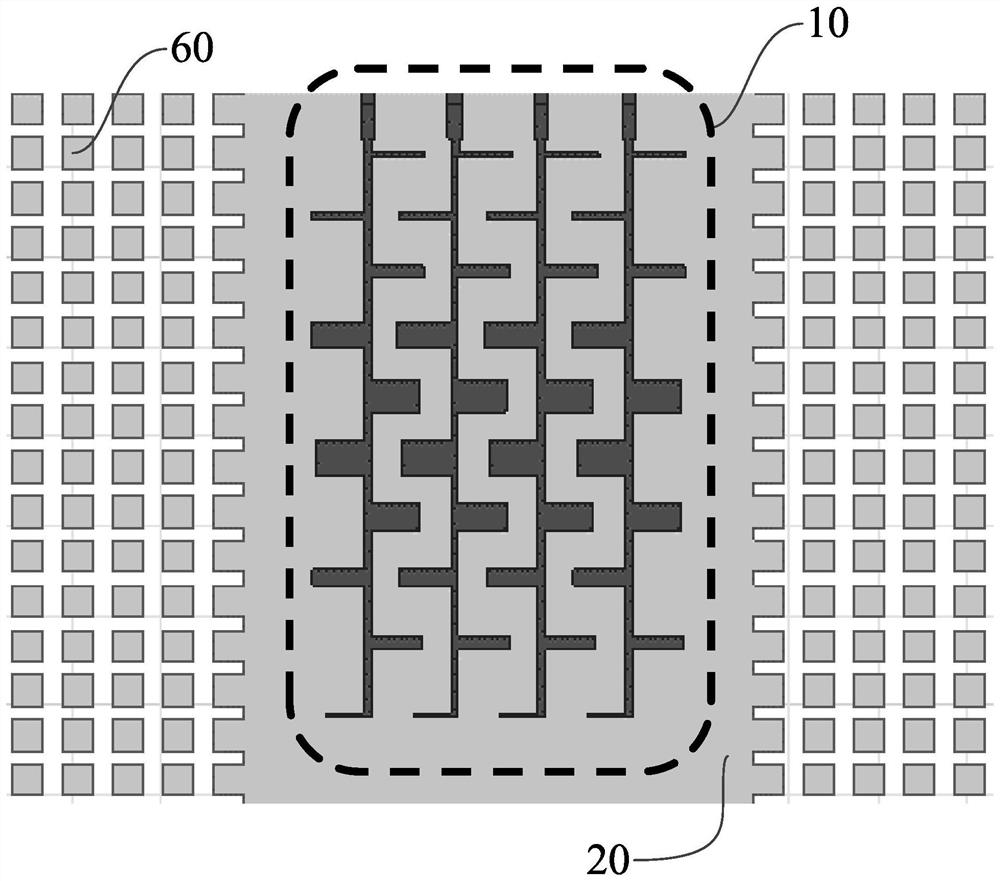

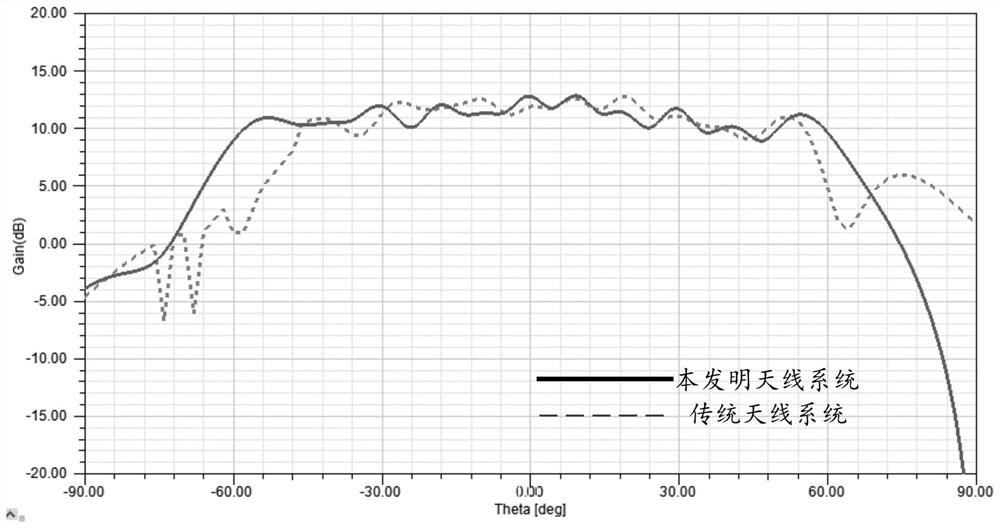

Antenna system and vehicle-mounted millimeter wave radar

PendingCN113540793AImprove perceptionEliminate pittingAntenna adaptation in movable bodiesIndividually energised antenna arraysIn vehicleEngineering

The embodiment of the invention relates to the technical field of antennas, and discloses an antenna system and a vehicle-mounted millimeter wave radar. The system comprises an antenna array and a first grounding layer and a second grounding layer of the antenna array, the antenna array is used for radiating electromagnetic waves to a free space, and a plurality of metal patches are arranged on a first PCB surface where the first grounding layer is located at intervals. The metal patches are used for adjusting the phase of a reflected electromagnetic wave formed after the electromagnetic wave is reflected. According to the embodiment of the invention, the wide-angle sensing capability of the antenna system is improved.

Owner:SHENZHEN SKYFEND TECH CO LTD

Method for repairing finish paint shrinkage cavity of car

ActiveCN102284409BDoes not affect appearanceLower level requirementsPretreated surfacesSpecial surfacesVarnishMaterials science

Owner:CHERY AUTOMOBILE CO LTD

A method for improving the indentation defects of high-quality aluminum alloy round ingot soaking heat treatment

The present invention relates to the technical field of heat treatment of aluminum alloys, and in particular to a method for improving indentation defects in soaking heat treatment of high-quality aluminum alloy round ingots, which specifically includes the following steps: S1: placing aluminum alloy round ingots on an aluminum Alloy plate; S2: Preheat the aluminum alloy round ingot, the preheating temperature range is 475-525°C, and the preheating time is 4-7h; S3: Homogenize the aluminum alloy round ingot, the homogenization temperature The range is 550~600℃, and the homogenization time is 3~10h. The method for improving the indentation defect of the high-quality aluminum alloy round ingot soaking treatment provided by the invention eliminates the indentation defect on the surface of the round ingot, improves the mechanical properties of the round ingot, and improves the quality of aluminum alloy products.

Owner:FUJIAN NANPING ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com