A process of controlling phosphated residue content

A technology of phosphating slag and content, applied in phosphating, metal material coating process, measuring device and other directions, can solve the problem of easy misjudgment, inaccurate slag content in phosphating solution, phosphating slag remover and regular pouring Can not adjust and other problems to achieve the effect of eliminating pits and accurate readings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

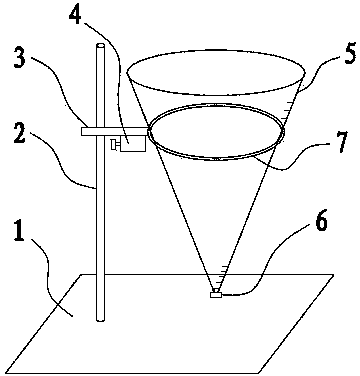

[0023] Embodiment: a kind of phosphating slag content control technology, adopts such as figure 1 The sedimentation measuring device shown was used for the measurement. figure 1 The shown device includes a support, and the support includes a base 1 placed on the table. The upper surface of the base 1 is provided with a vertical pole 2. The vertical pole 2 is provided with a cantilever 3 adjustable up and down, and the end of the cantilever is connected with a ring bracket 7 . The ring-shaped support is provided with a tapered measuring cup 5 with a large top and a small bottom. The upper side wall of the tapered measuring cup 5 is engraved with a scale for reading the amount of phosphating solution, and the bottom side wall is engraved with a scale for reading the amount of sediment. The bottom cone top of the conical measuring cup 5 is blocked by a detachable plugging screw 6, which can be unscrewed during cleaning.

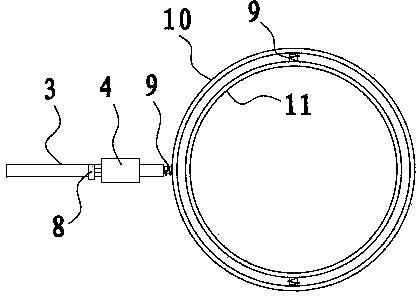

[0024] Such as figure 1 , 2 As shown, cantilever 3 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com