Wheel steel with excellent welding performance and production method

A technology of welding performance and wheel steel, which is applied in the field of hot-rolled steel and production, can solve the problems of not being able to adapt to the development and use trend of high-strength materials in the current price segment, low strength, and not being able to meet the requirements for the use of off-road wheel steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

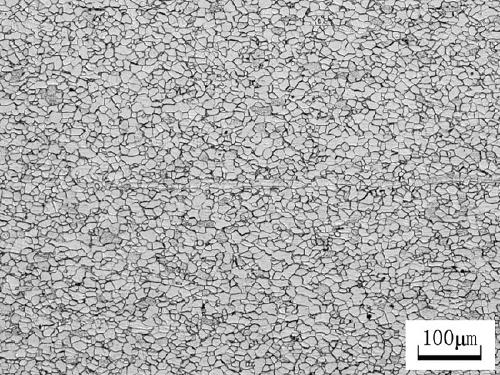

Image

Examples

Embodiment Construction

[0046] The present invention is described in detail below:

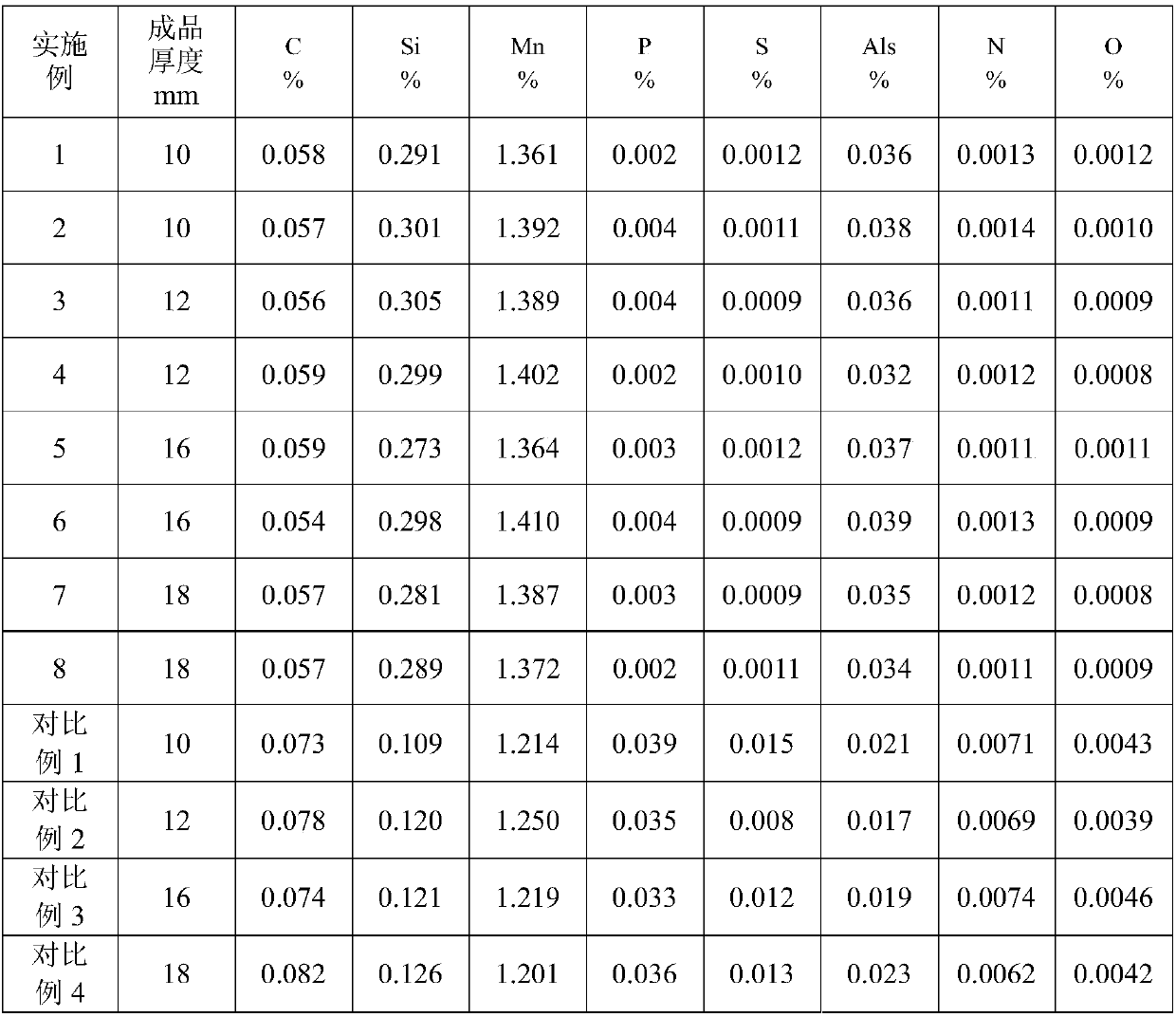

[0047] Table 1 is the value list of each embodiment of the present invention and comparative example;

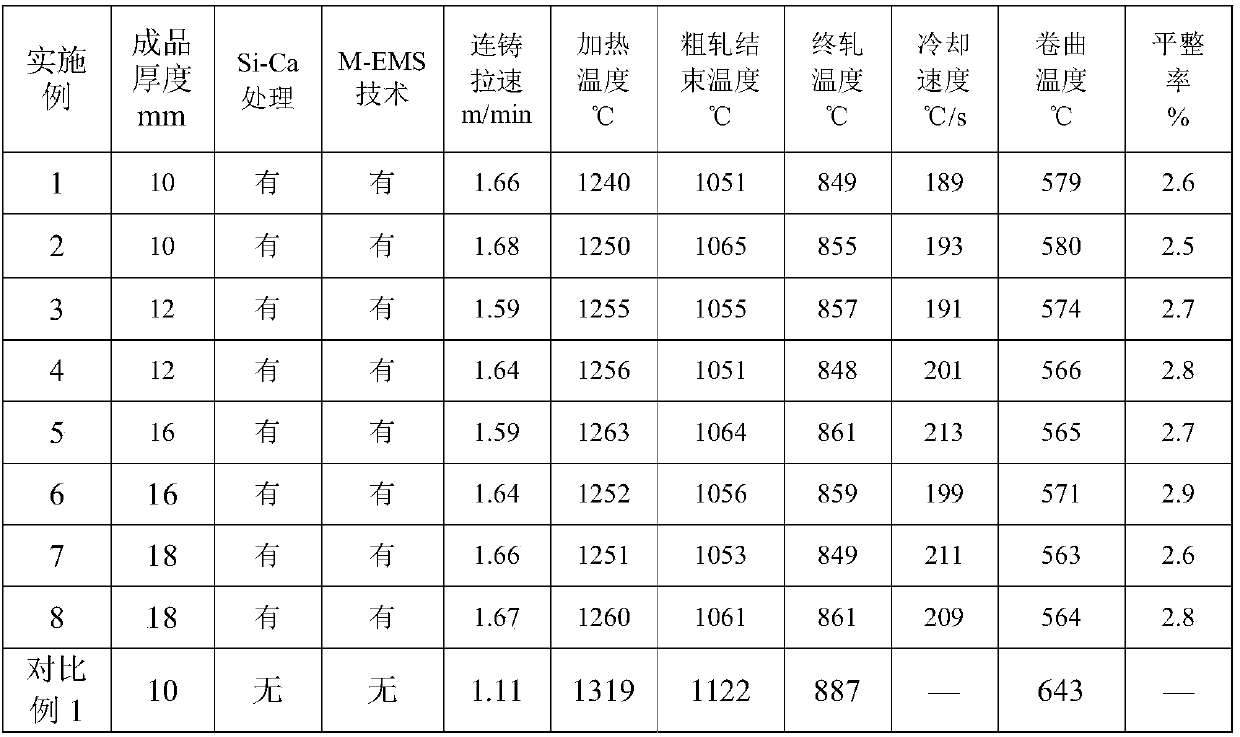

[0048] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0049] Table 3 is each embodiment of the present invention and comparative example performance detection situation list;

[0050] Table 4 is a list of the composition and weight percentage content of the slag of each embodiment of the present invention and comparative examples.

[0051] Each embodiment of the present invention is produced according to the following steps:

[0052] 1) After being smelted in a converter, enter the LF furnace for out-of-furnace refining; and use argon blowing and stirring in the whole process of out-of-furnace refining in the LF furnace;

[0053] 2) Carry out RH vacuum treatment; control the end of vacuum treatment, P≤0.008% and S≤0.005% in molten steel, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com