Out-sync swaging drawing forming mould and forming process thereof

A molding die and molding process technology, which is applied in the field of non-synchronous pressing and drawing molding dies and its molding process, can solve problems that affect the mold manufacturing cycle, complex product shapes, and complex shape changes, and achieve insufficient wrinkling and cracking Problems, reasonable design of forming process, and the effect of improving drawing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

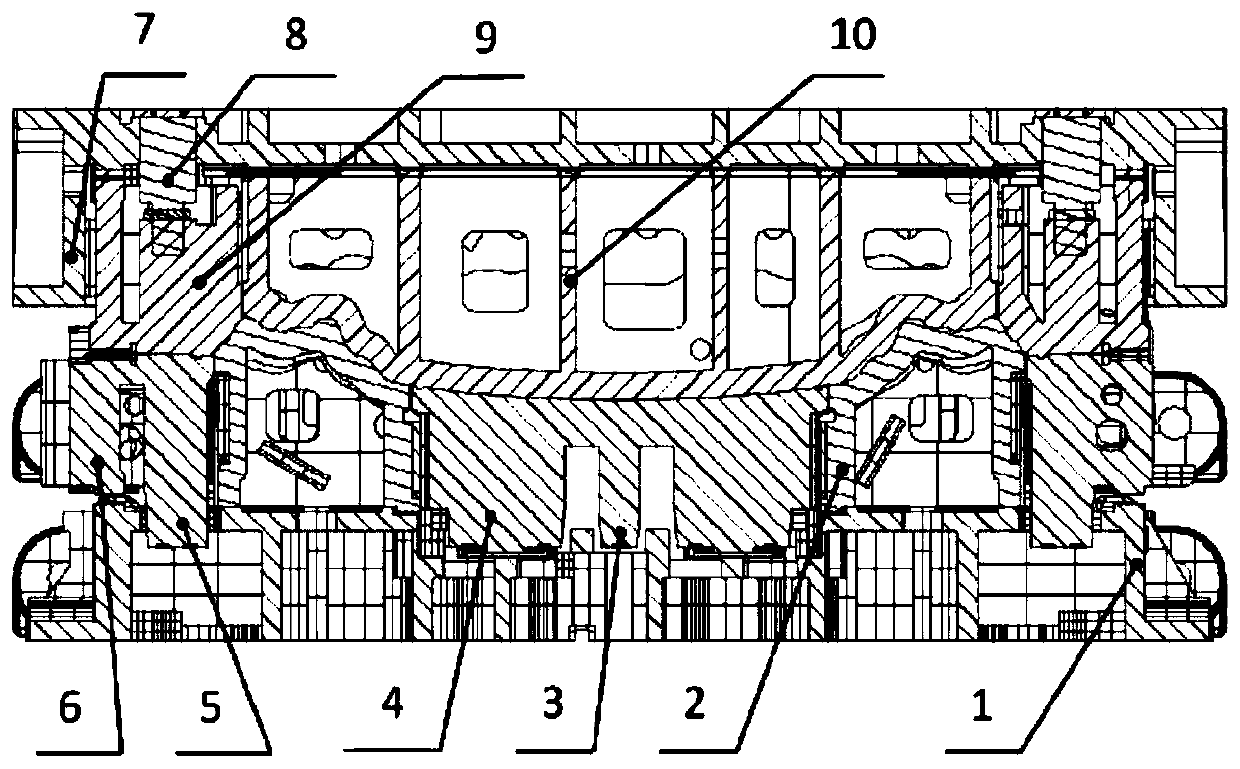

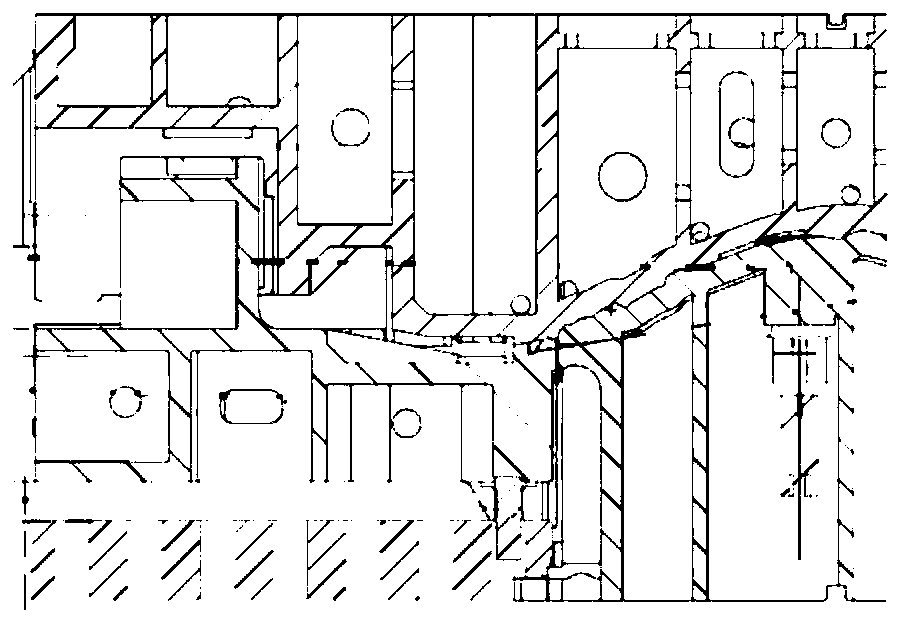

[0033] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

[0034] The asynchronous pressing and drawing forming die includes an upper die body, a lower die base, a punch and a die, the die is set on the lower part of the upper die body, the punch is set on the upper part of the lower die base, and the punch is fixed on the lower die On the seat, the outer side of the punch is provided with a movable lower blank holder, and the center of the punch is provided with a movable support core, the punch and the support core are slidably fitted, and the die is fixed on the upper die body to form a fixed convex Die, the outer side of the die is provided with a movable upper binder ring, the upper binder ring and the lower binder ring are set up and down oppositely, and the lower surface of the die is set opposite to the upper surface of the punch and the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com