Automatic drawing method and system for open pores in hull drawing, equipment and storage medium

An automatic drawing and drawing technology, applied in the field of drawing, can solve the problems of openings that cannot directly and quickly draw complex shapes, manual preparation of opening schedules, manual marking or numbering of opening sizes one by one, etc., to optimize the opening drawing effect. , Improve the overall drawing quality and simplify the effect of annotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

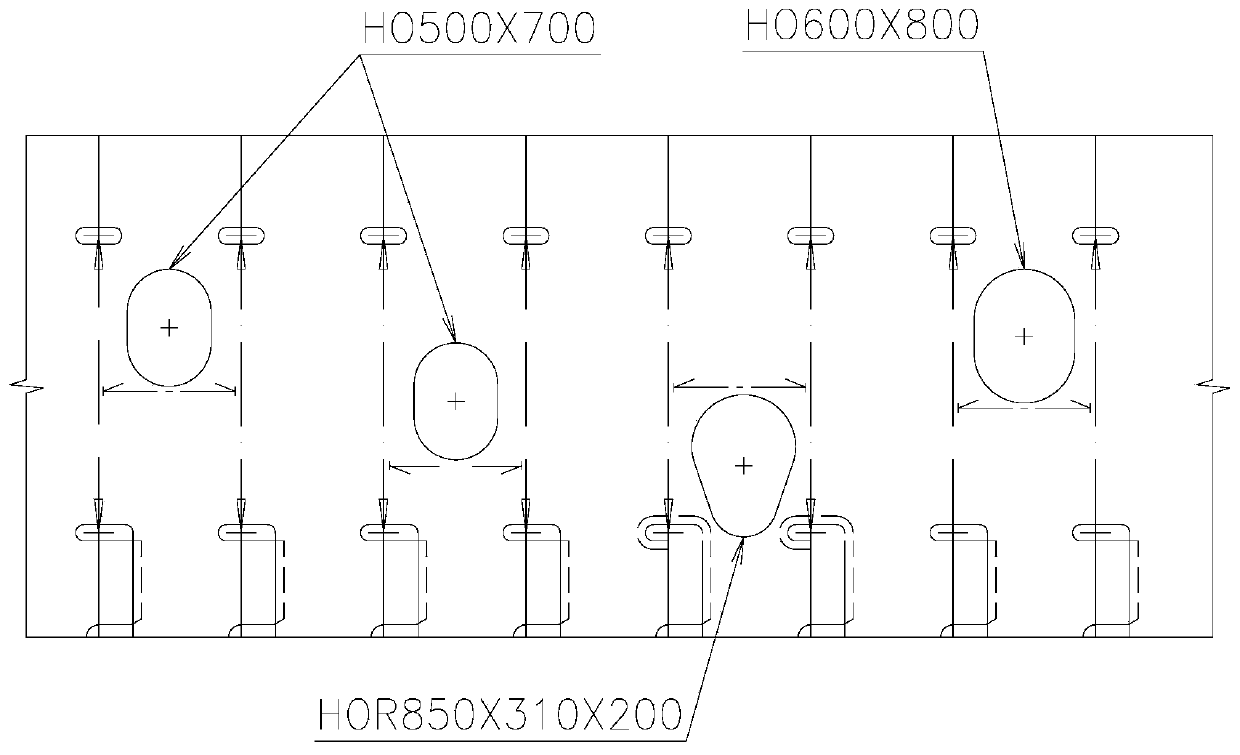

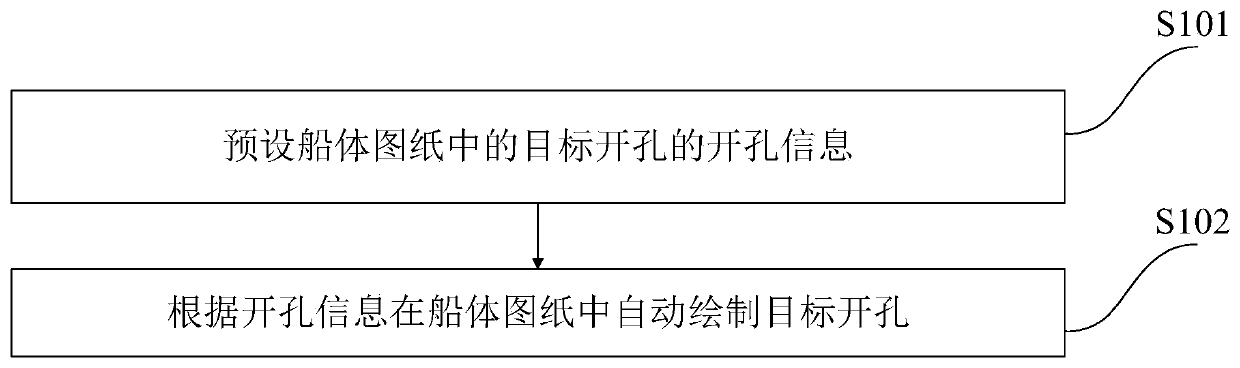

[0054] Such as image 3 As shown, the method for automatically drawing holes in the hull drawing of this embodiment includes:

[0055] S101, preset the hole information of the target hole in the hull drawing;

[0056] Wherein, the hole information includes, but is not limited to, the hole type, hole size of the target hole, first position information in the hull drawing, and hole identification information;

[0057] Among them, the hole identification information is used to characterize different target holes.

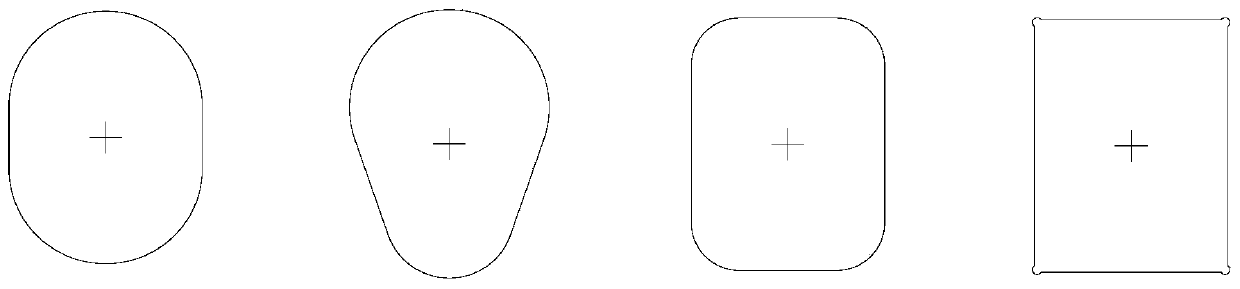

[0058] Specifically, the types of openings include conventional shapes such as circles, ellipses, rectangles, and regular polygons, as well as other special openings with complex shapes.

[0059] The opening size includes a plurality of opening parameters used to determine the shape and size of the target opening; different opening types correspond to different opening parameter combinations.

[0060] S102: Automatically draw the target opening in the ship hull drawing according ...

Embodiment 2

[0063] Such as Figure 4 As shown, the automatic drawing method of openings in the hull drawing of this embodiment is a further improvement of Embodiment 1, specifically:

[0064] After step S102, it further includes:

[0065] S103: Obtain the hole type and hole size corresponding to each target hole;

[0066] S104: Obtain target openings with the same opening type and opening size and set the same opening number;

[0067] The setting process of the opening number is automatically completed and can be carried out in batches.

[0068] Specifically, group the target openings with the same opening type and opening size into a group;

[0069] Set the target openings in the same group to correspond to the same opening numbers;

[0070] Sort the different groups, and set the corresponding hole number for each group according to the sort.

[0071] In addition, additional attributes of graphics are given to the drawn target openings. Specifically, data in a specific format can be added to the conv...

Embodiment 3

[0084] Such as Image 6 As shown, the automatic drawing system for openings in the hull drawing of this embodiment includes a hole information preset module 1 and an automatic drawing module 2.

[0085] The opening information preset module 1 is used to preset the opening information of the target opening in the hull drawing;

[0086] Wherein, the opening information includes, but is not limited to, the opening type of the target opening, the opening size, the first position information in the hull drawing, and the opening identification information;

[0087] Among them, the hole identification information is used to characterize different target holes.

[0088] Specifically, the types of openings include conventional shapes such as circles, ellipses, rectangles, and regular polygons, as well as other special openings with complex shapes.

[0089] The opening size includes a plurality of opening parameters for determining the shape and size of the target opening; different opening types...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com