Looping head automatic reset device

A technology of automatic reset and loop forming head, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., and can solve problems such as coil quality defects, coil looseness, product quality and output impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

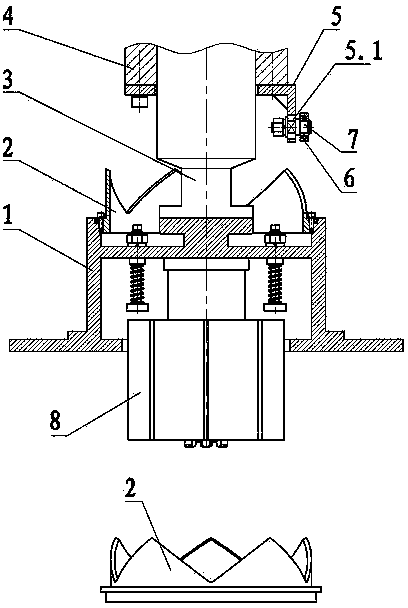

[0012] Such as figure 1 In the automatic reset device of the loop forming head shown, the loop forming head 1 is fixedly connected to the sliding shaft 3, and the circumferential direction of the loop forming head 1 is uniformly provided with axial gaps matching the corresponding process (not shown in the figure), and the sliding shaft 3 It can be slidably connected to the inner hole of the sliding sleeve 4, the sliding sleeve 4 is fixedly connected to the fuselage, and the bottom surface of the sliding sleeve 4 is fixedly connected with the adjustable positioning plate 5, and the adjustable positioning plate 5 can be adjusted relative to the circumferential position of the sliding sleeve 4. Adjustment, the side of the adjustable positioning disc 5 is provided with a long adjustment hole 5.1 along the axial direction, a pin shaft 7 is installed in the long adjustment hole 5.1, and a roller is provided on the pin shaft 7, and the roller is a bearing 6. The top of ring head 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com