A modular modular expansion device

A telescopic device and modular technology, applied in construction, bridge construction, bridges, etc., can solve the problems of difficult to ensure locking quality, narrow working space, difficult operation, etc., to achieve easy maintenance and handling, guarantee stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

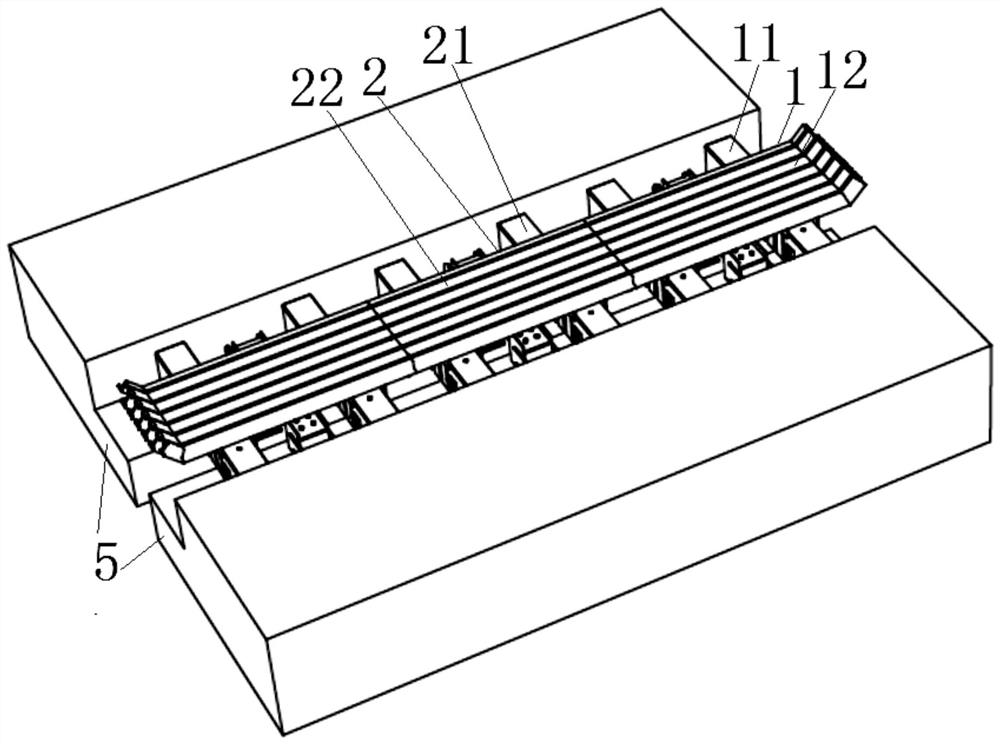

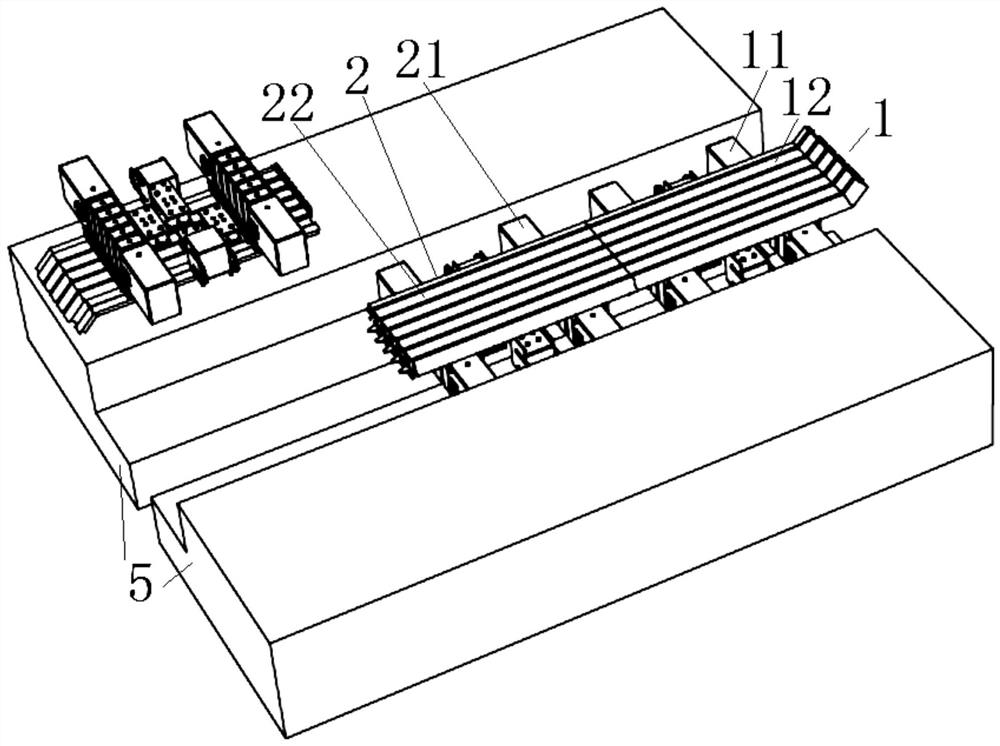

[0032] see figure 1 , figure 2 and image 3 As shown, the present invention has three sections of telescopic units along the transverse length, and the sequential butt joint lengths of these three sections of telescopic units just correspond to the design requirements of the modular telescopic device length at 5 places of the end beam on the bridge. The structure of each segment of the telescopic unit is basically the same as that of the conventional modular telescopic device, the biggest difference being that the transverse length is shorter than that of the integral modular telescopic device. Specifically, taking the telescopic unit-1 as an example, the telescopic unit-1 is mainly composed of two longitudinal joists-11 arranged longitudinally, a support box that is movably assembled at both ends of each longitudinal joist-11, and arranged horizontally. A plurality of beam sections 12 that are movably assembled on each longitudinal joist 11 (wherein the beam sections that ...

Embodiment 2

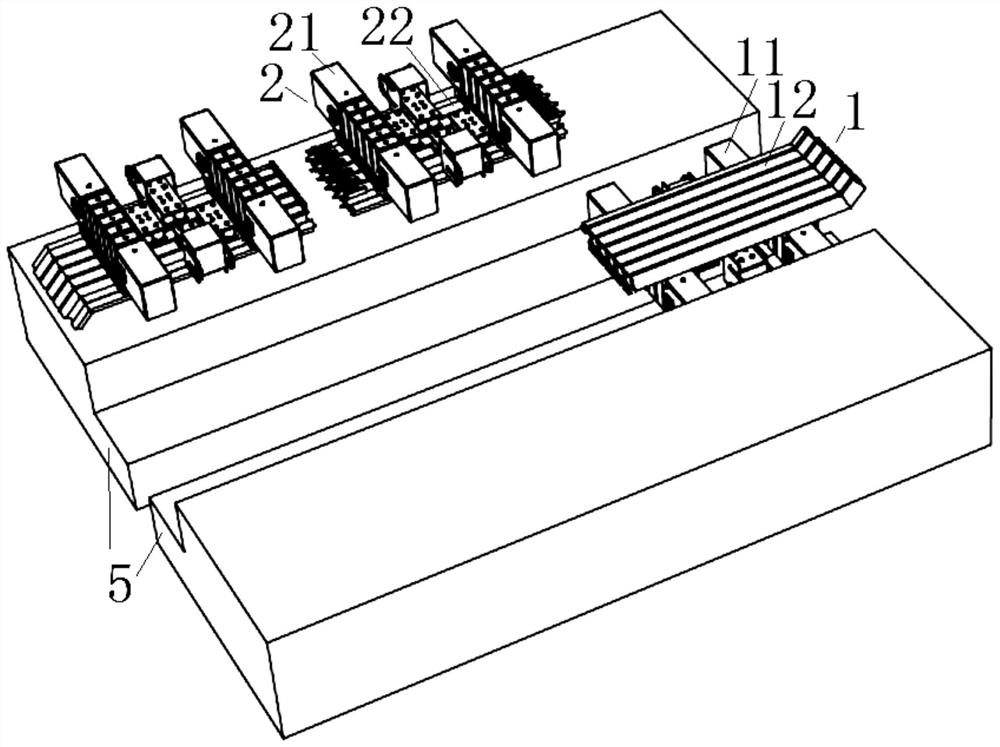

[0046] The present invention has four sections of telescopic units along the transverse length, and the sequential butt joint lengths of these four sections of telescopic units just correspond to the length of the modular telescopic device required by the design at the end beam on the bridge. The structure of each segment of the telescopic unit is basically the same as that of the conventional modular telescopic device, the biggest difference being that the transverse length is shorter than that of the integral modular telescopic device. Specifically, taking the telescopic unit 1 as an example, the telescopic unit 1 mainly consists of a longitudinal joist 1 arranged longitudinally, a support box at both ends of the longitudinal joist movably assembled on the longitudinal joist in a horizontal arrangement A plurality of beam sections on one (among them, the beam sections on both sides and connected with the corresponding supporting box are side beams, and the beam sections betwe...

Embodiment 3

[0059] The other content of this embodiment is the same as that of Embodiment 1, the difference is that there is a positioning pin mechanism between the parts of the two adjacent telescopic units one by one corresponding to the beam section, for example, the one-to-one corresponding beam section with the positioning pin mechanism and the one without The one-to-one corresponding beam sections of the positioning pin mechanism are arranged alternately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com