Quick pipe joint and joint assembly

A kind of pipe joint, fast technology, applied in the direction of engine components, engine seals, mechanical equipment, etc., can solve the problems of high use cost, difficult installation and disassembly, etc., to achieve the effect of reduced processing cost, low cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

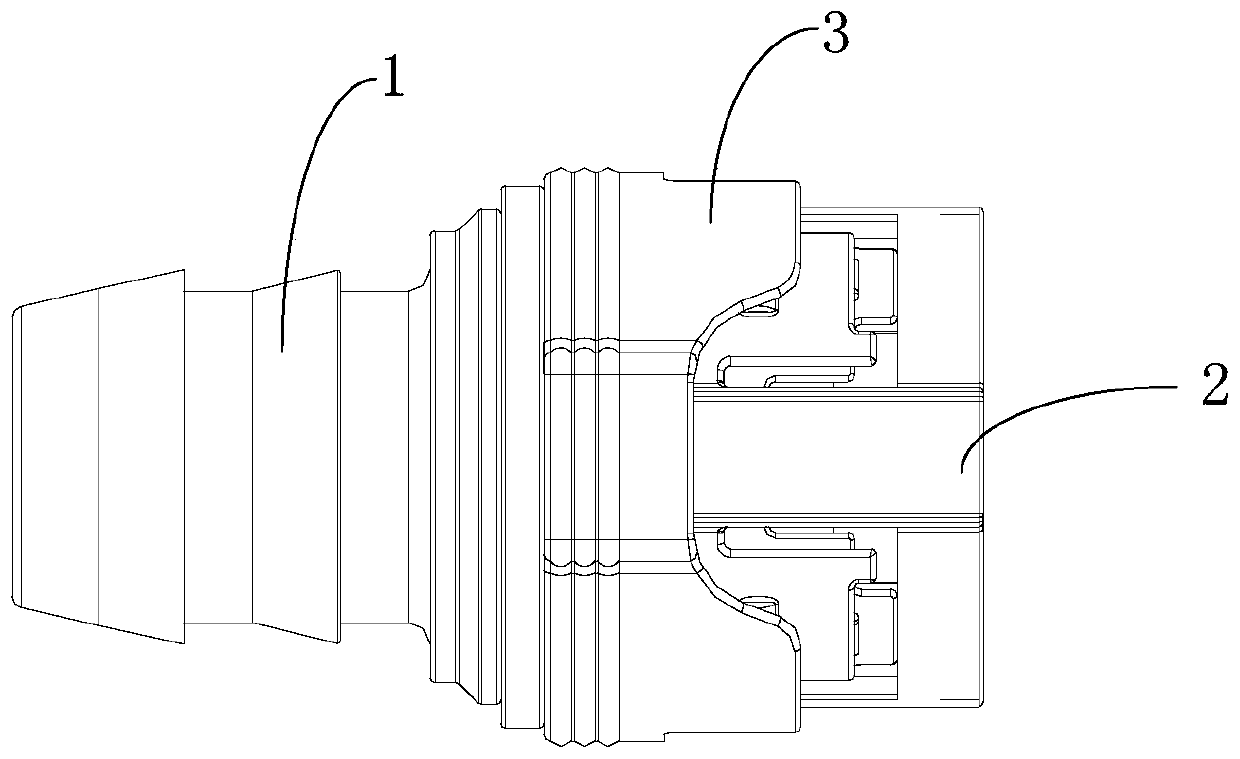

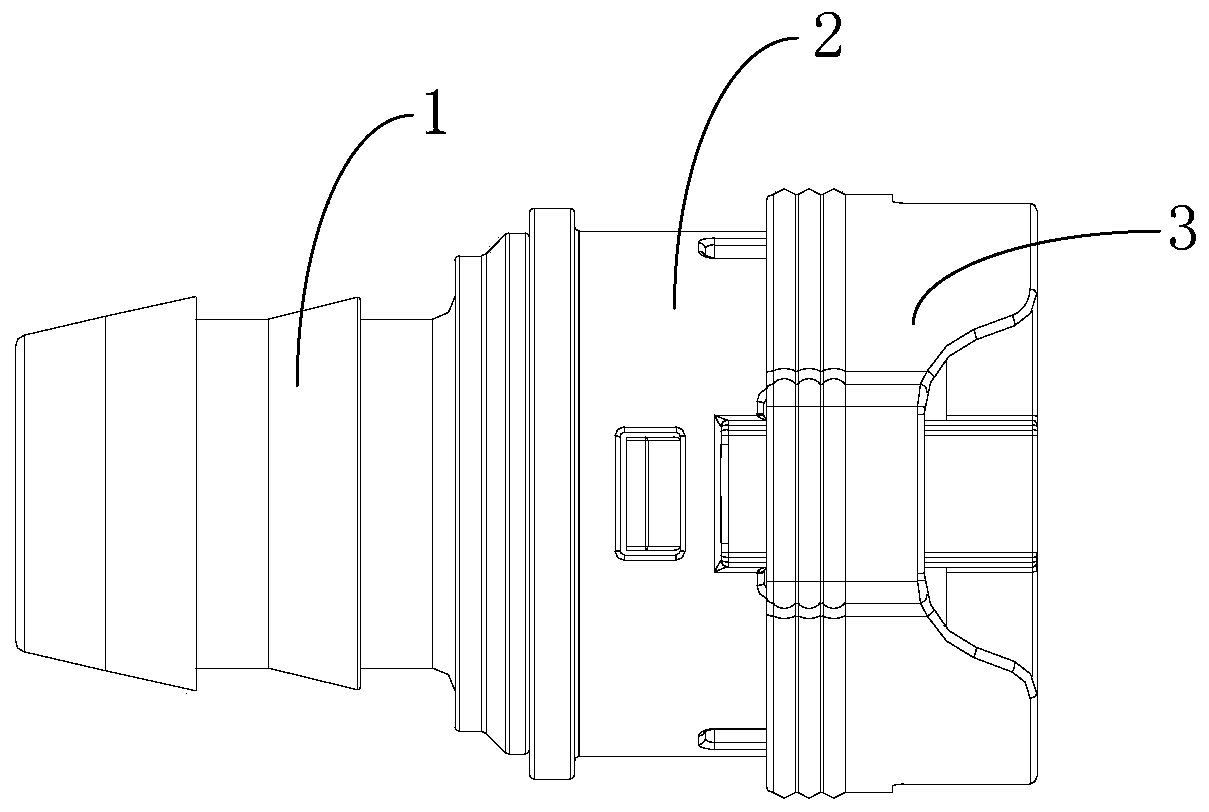

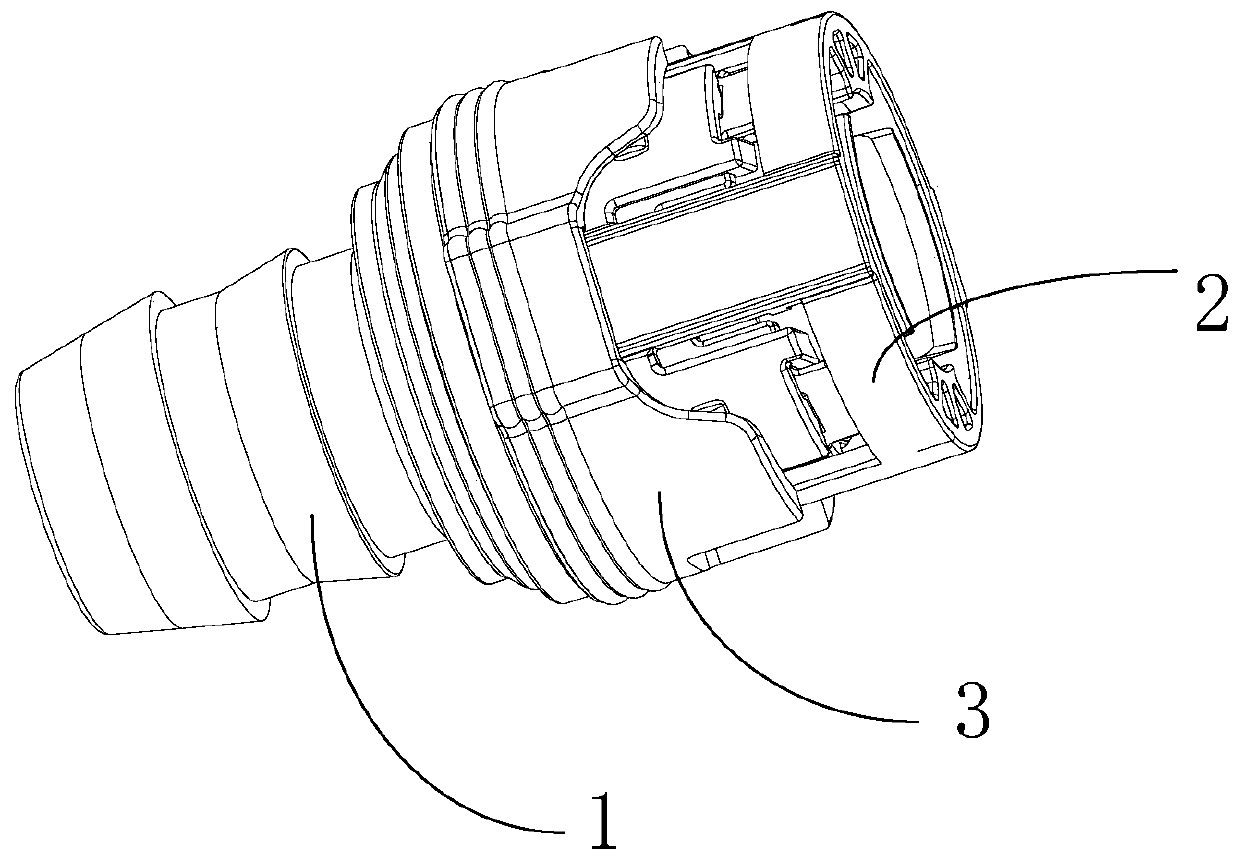

[0043] This embodiment provides a quick fitting, please refer to Figure 1 to Figure 9 , combined with Figure 10 , Figure 11 , and focus on the Figure 4 , the quick pipe joint includes a joint body 1 and an integrated snap sleeve 2; the joint body 1 has a lumen for connecting with the counterpart 0; the integrated snap sleeve 2 includes a snap sleeve 21 and is connected to the The inner guide sleeve 23 of the buckle sleeve 21; the joint body 1 is connected to the buckle sleeve 21 and / or the guide sleeve 23 by inserting one end between the buckle sleeve 21 and the guide sleeve 23; on the inner wall surface of the buckle sleeve 21 There is provided on the upper part a counterpart piece engagement protrusion 211 for clamping with the counterpart piece 0, and the buckle sleeve 21 is made of elastic material.

[0044] Among them, "and / or" means that the joint body 1 is connected to the buckle sleeve 21 by inserting one end between the buckle sleeve 21 and the guide sleeve 23,...

Embodiment 2

[0057] This embodiment provides a joint assembly, refer to Figure 10 and Figure 11 , the joint assembly includes counterpart 0 and quick pipe joint.

[0058] combined reference Figure 1 to Figure 9 , the quick pipe joint includes a joint body 1 and an integrated snap sleeve 2; the joint body 1 has a lumen for connecting with the counterpart 0; the integrated snap sleeve 2 includes a snap sleeve 21 and is connected to the The inner guide sleeve 23 of the buckle sleeve 21; the joint body 1 is connected to the buckle sleeve 21 and / or the guide sleeve 23 by inserting one end between the buckle sleeve 21 and the guide sleeve 23; on the inner wall surface of the buckle sleeve 21 There is provided on the upper part a counterpart piece engagement protrusion 211 for clamping with the counterpart piece 0, and the buckle sleeve 21 is made of elastic material.

[0059] Among them, "and / or" means that the joint body 1 is connected to the buckle sleeve 21 by inserting one end between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com