Ultrasonic/air flotation hybrid noncontact automatic transporter

An automatic transportation, ultrasonic technology, applied in transportation and packaging, non-mechanical conveyors, conveyors, etc., to achieve the effect of easy structure, easy transportation speed, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

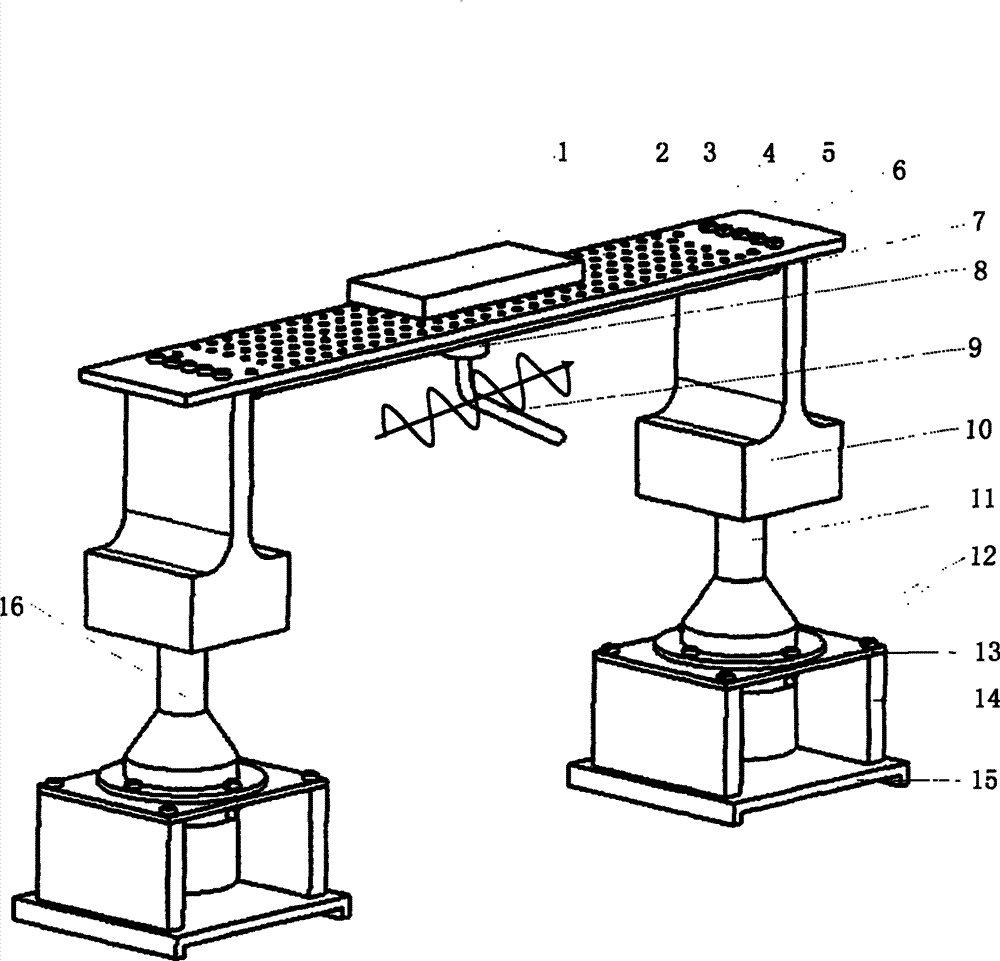

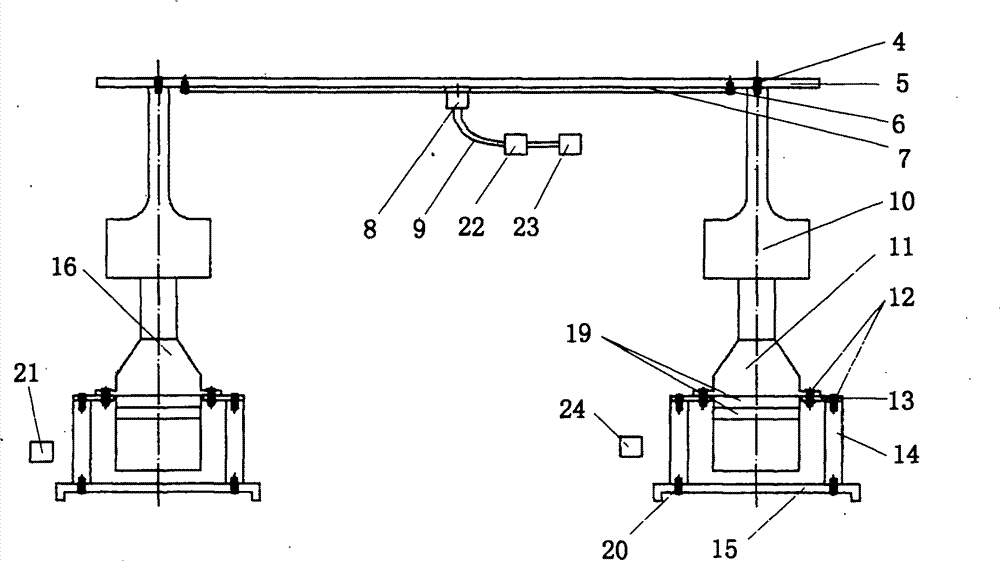

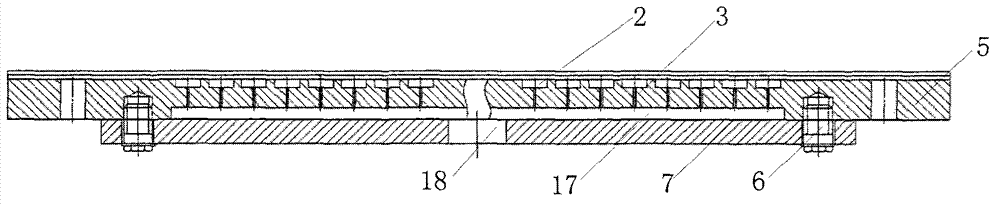

[0029] see figure 2 , image 3 and Figure 4 , the vibrating plate (5) and the square thin plate (7) are connected together by screws (6). Then the vibrating plate (5) and the left and right two horn-type horns (10) are fixed together by screws 4, and the two horns are connected with the transmitting ultrasonic transducer (16) and the receiving ultrasonic transducer respectively. Device (11) is fixed together. The two ultrasonic transducers are fixed together with the base plate (13) with hexagon socket bolts (12). The base plate (13), the side plate (14), and the base (15) are connected together with hexagon socket head bolts (12) and screws (20) respectively. The gas from the air compressor (23) enters the pressure stabilizing valve (22) after being filtered and then flows into the groove (17) of the vibrating plate. The receiving ultrasonic transducer (11) and the emitting ultrasonic transducer (16) are respectively connected with the ultrasonic generator (24) and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com