Winding device and method of spiral wires for traveling wave tubes and winding method

A helix and winding technology, applied in the field of microwave vacuum devices, can solve the problems of difficulty in guaranteeing the inner and outer diameter and pitch accuracy of the helix, affecting the production efficiency and working performance of the traveling wave tube, and poor winding performance, etc. Pitch accuracy, ensure production efficiency and work performance, and ensure the effect of inner and outer diameter accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

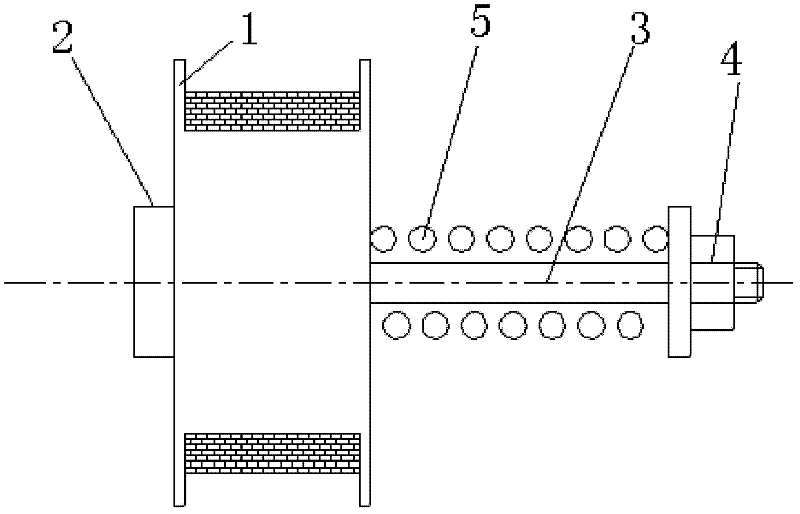

[0030] The winding device for the helical wire for traveling wave tubes includes a lathe, on the tool rest of the lathe, a mounting jig for installing the entire strip is connected, on the jig of the lathe, a core rod is installed, on the mounting jig and the A tensioning fixture is provided between the core rods, and one end of the whole strip drawn out bypasses the tensioning clamps to reach the position of the core rods and is fixed on the core rods.

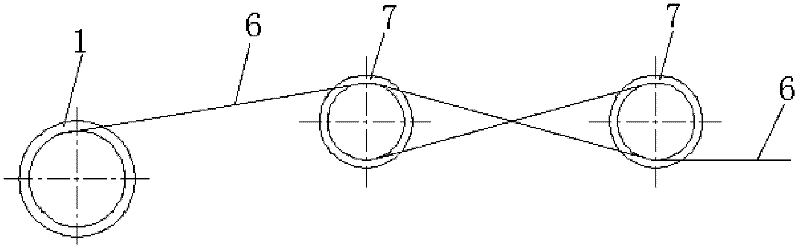

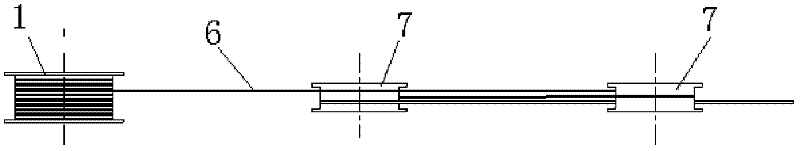

[0031] Figure 1 to Figure 4 It is a structural schematic diagram of the installation jig, tensioning jig and core rod in the winding device of the helical wire for traveling wave tubes.

[0032] Such as figure 1 As shown, the installation fixture includes a bracket 2 and a bracket shaft 3, one end of the bracket shaft 3 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com