Module and method for producing same

A manufacturing method and molding resin technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as difficulty in ensuring module connection reliability, and achieve the effect of preventing poor connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

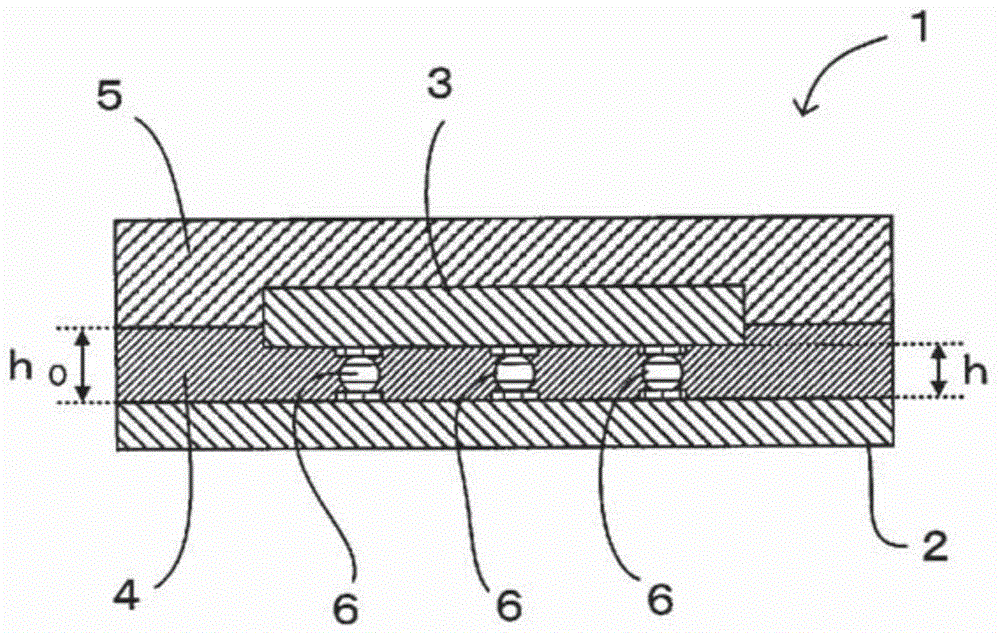

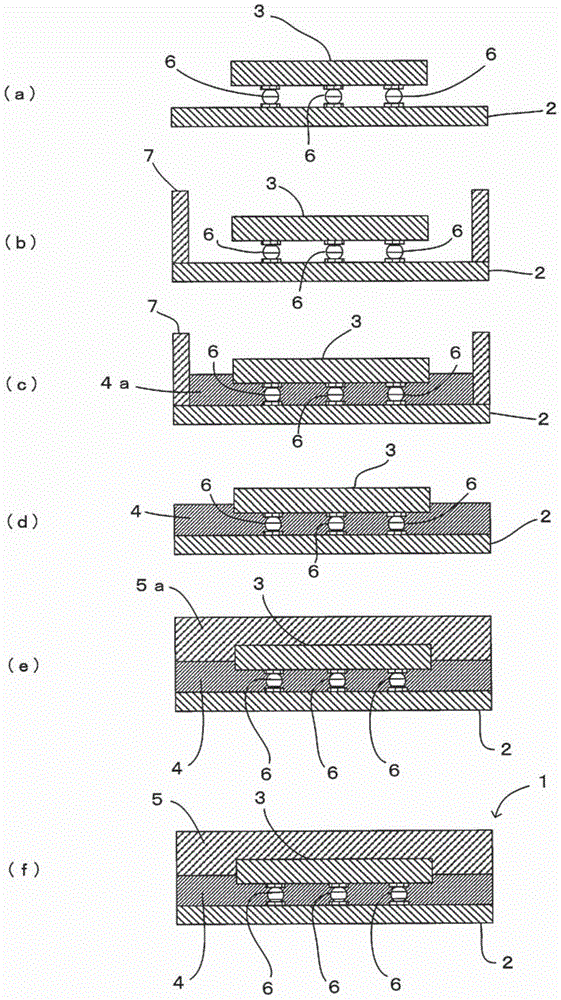

[0039] refer to figure 1 The module 1 according to Embodiment 1 of the present invention will be described. figure 1 It is a sectional view of the module 1 of Embodiment 1.

[0040] The module 1 of this embodiment is as figure 1 As shown, it includes: a wiring substrate 2; electronic components 3 mounted on one main surface of the wiring substrate 2; formed on the entire surface of one main surface of the wiring substrate 2, and connecting one main surface of the wiring substrate 2 with the electronic components an underfill resin layer 4 filling the gaps between the devices 3 ; and a molding resin layer 5 formed to cover the electronic components 3 and the underfill resin layer 4 .

[0041] The wiring substrate 2 is made of, for example, a glass epoxy substrate, a low temperature co-fired ceramic (LTCC) substrate, a glass substrate, etc., and wiring electrodes and / or via conductors are formed on its main surface and / or inside. In addition, any one of a multilayer substr...

Embodiment approach 2

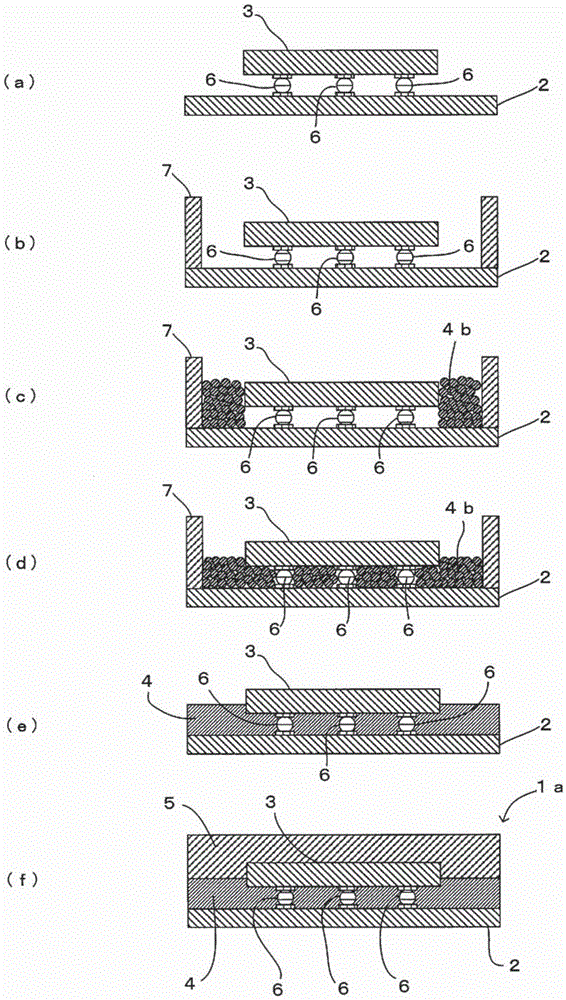

[0064] refer to image 3 The module 1a according to Embodiment 2 of the present invention will be described. in addition, image 3 It is a figure for demonstrating the manufacturing method of the module 1a of Embodiment 2, image 3 (a)~ image 3 (f) shows each process.

[0065] Module 1a of this embodiment and reference figure 1 and figure 2 The module 1 of Embodiment 1 described above is different in that the underfill resin layer 4 is formed using the powdered resin 4 b in the manufacturing method. The other configurations are the same as those of the module 1 in Embodiment 1, and thus the description of the configurations will be omitted by denoting the same configurations with the same reference numerals.

[0066] in addition, image 3 In each process of the manufacturing method of the module 1a shown, image 3 The steps shown in (a) to (b) correspond to figure 2 The steps shown in (a) to (b), image 3 The process shown in (f) corresponds to figure 2 (e), si...

Embodiment approach 3

[0075] refer to Figure 4 Module 1b according to Embodiment 3 of the present invention will be described. in addition, Figure 4 is a cross-sectional view of module 1b.

[0076] Module 1b of this embodiment and reference figure 1 The differences of the module 1 of the first embodiment described are as follows: Figure 4 As shown, the molding resin layer 5 has a double-layer structure. The other configurations are the same as those of the module 1 in Embodiment 1, and thus the description of the configurations will be omitted by denoting the same configurations with the same reference numerals.

[0077] In this case, the molded resin layer 5 is composed of the first molded resin layer 5b disposed adjacent to the upper side of the underfill resin layer 4 and the second molded resin layer disposed above the first molded resin layer 5b. The resin layer 5c is formed. In addition, the particle diameter of the filler contained in the first molded resin layer 5b and the particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com