Electrostatic actuator, droplet discharging head, droplet discharging apparatus, electrostatic device

The technology of electrostatic driver and droplet spray head is applied in the field of electrostatic equipment, which can solve the problems of increasing the amount of sealing, deviation of the sealing state, and time-consuming, and achieves the effect of preventing poor connection, reducing the amount of sealing and reliable sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Embodiment 1

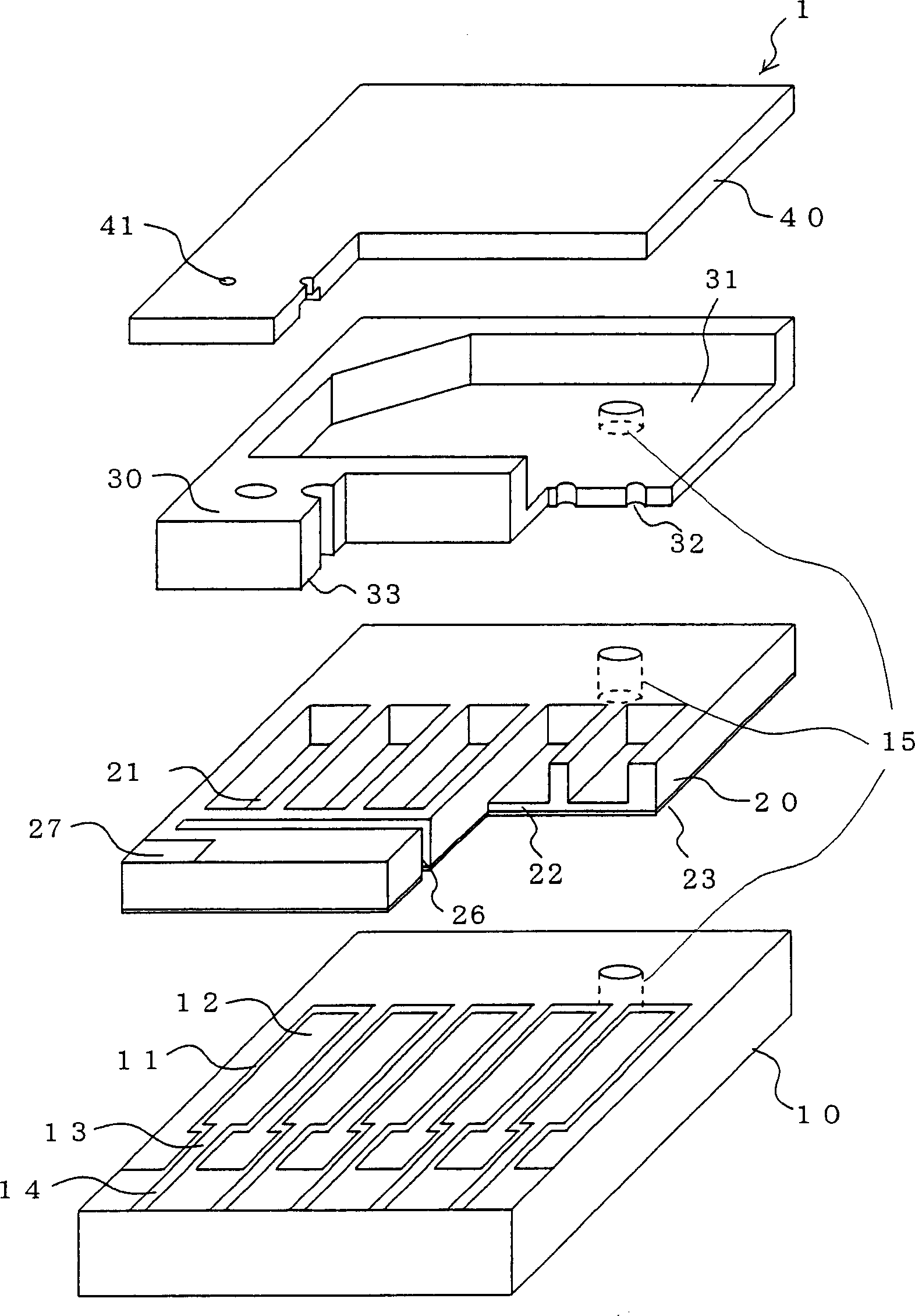

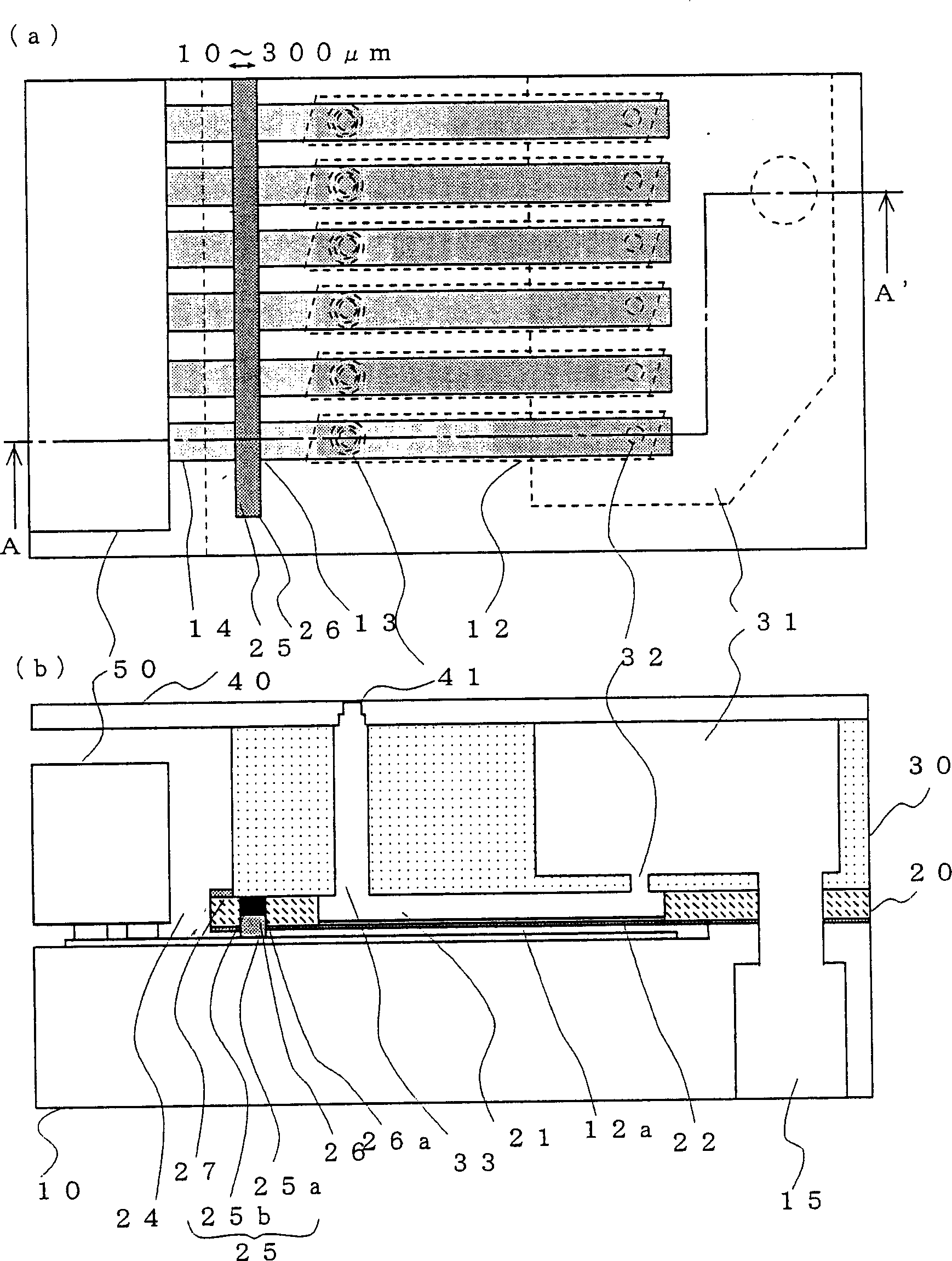

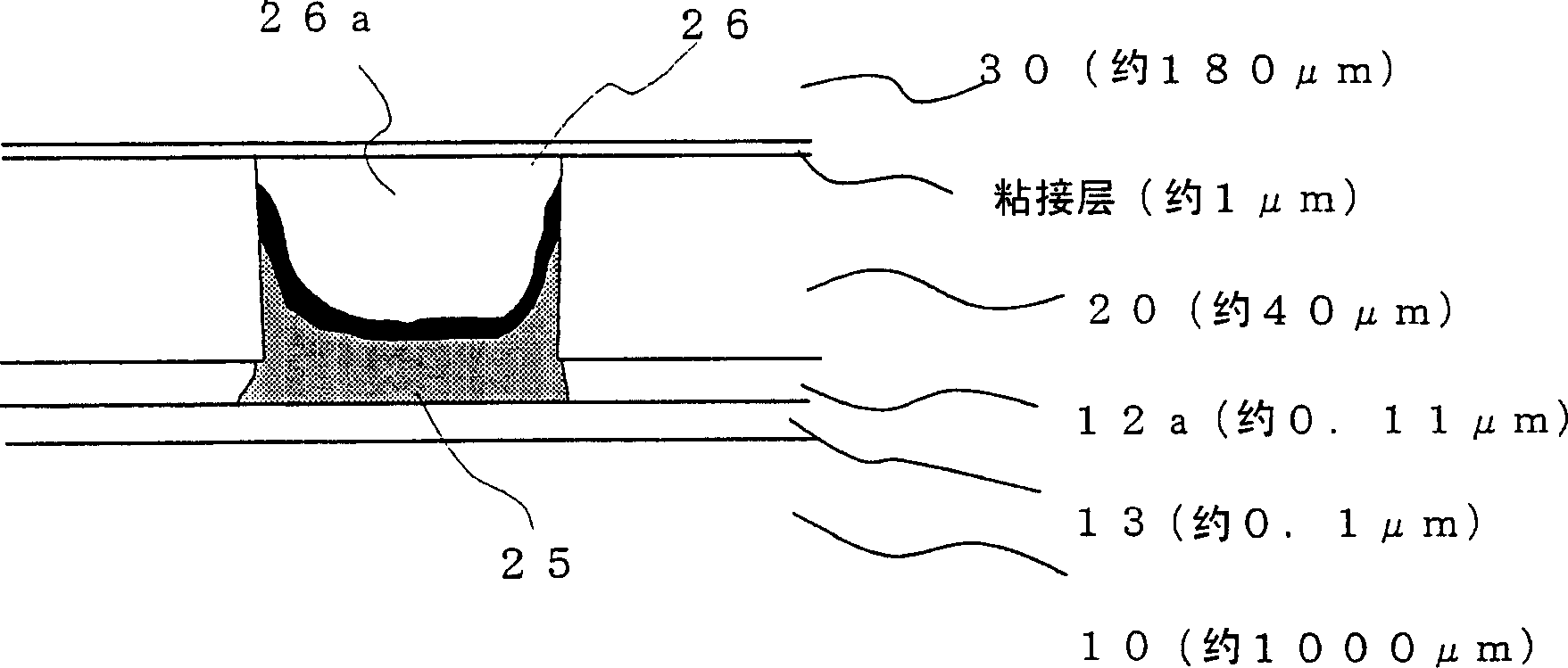

[0090] figure 1 It is an exploded view showing the liquid drop discharge head according to Embodiment 1 of the present invention. figure 1 A portion of a droplet extruder is shown. in addition, figure 2 It is a figure which shows the top view and longitudinal cross-sectional view of a droplet ejection head. In this embodiment, for example, a face eject type droplet ejection head will be described as a representative device using an electrostatic drive driven electrostatically. (Again, in order to illustrate the constituent parts and facilitate viewing, including figure 1 In addition, in the following drawings, the relationship of the size of each component may differ from actual components. In addition, the upper side in the drawing is referred to as the upper side, and the lower side is referred to as the lower side for description).

[0091] Such as figure 1 As shown, the droplet ejection head of the present embodiment is constituted by stacking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com