Multilayer printed wiring board and method for fabrication thereof

A technology of multi-layer printing and production method, applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve problems such as disadvantages, and achieve the effect of preventing connection deterioration, damage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

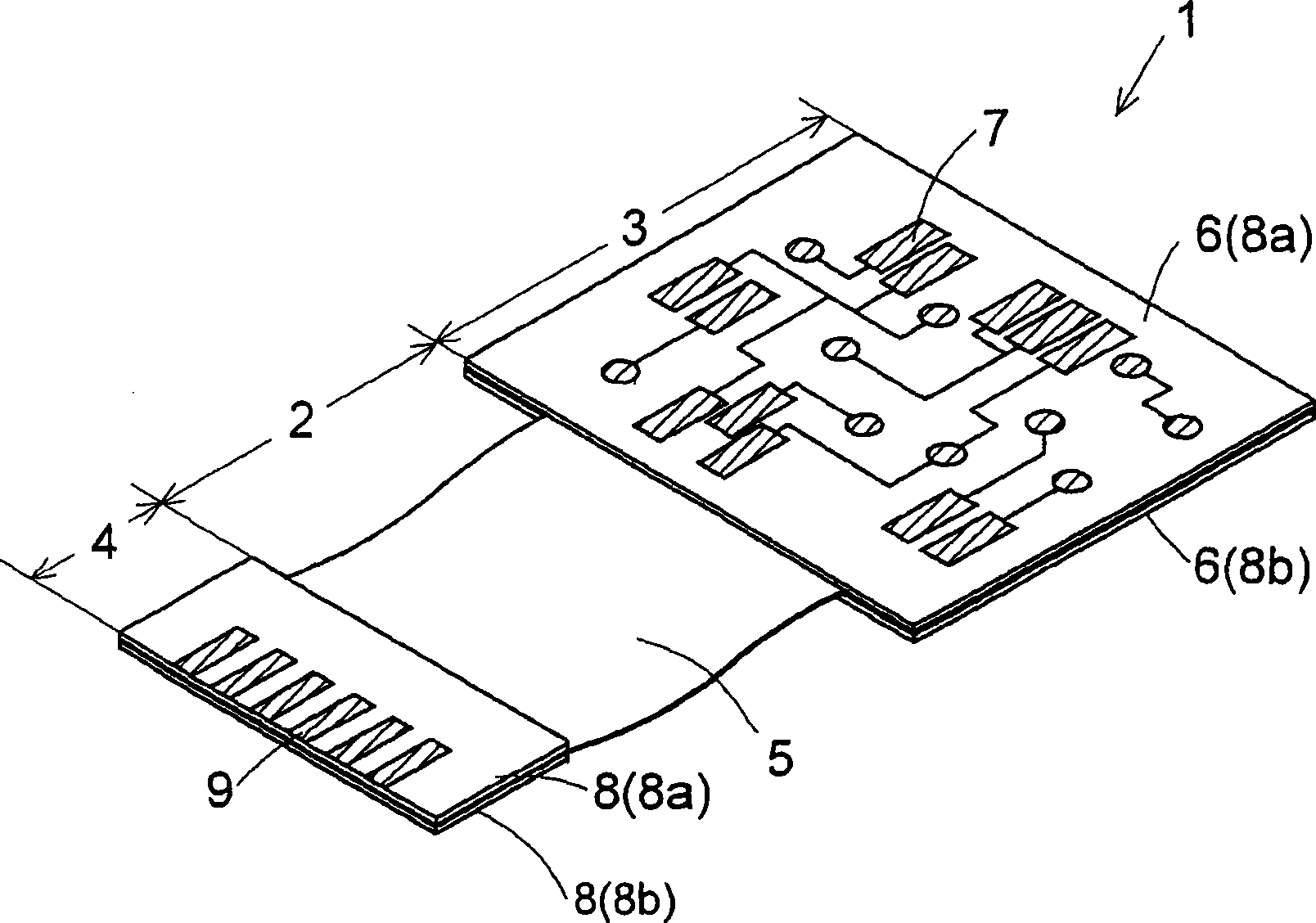

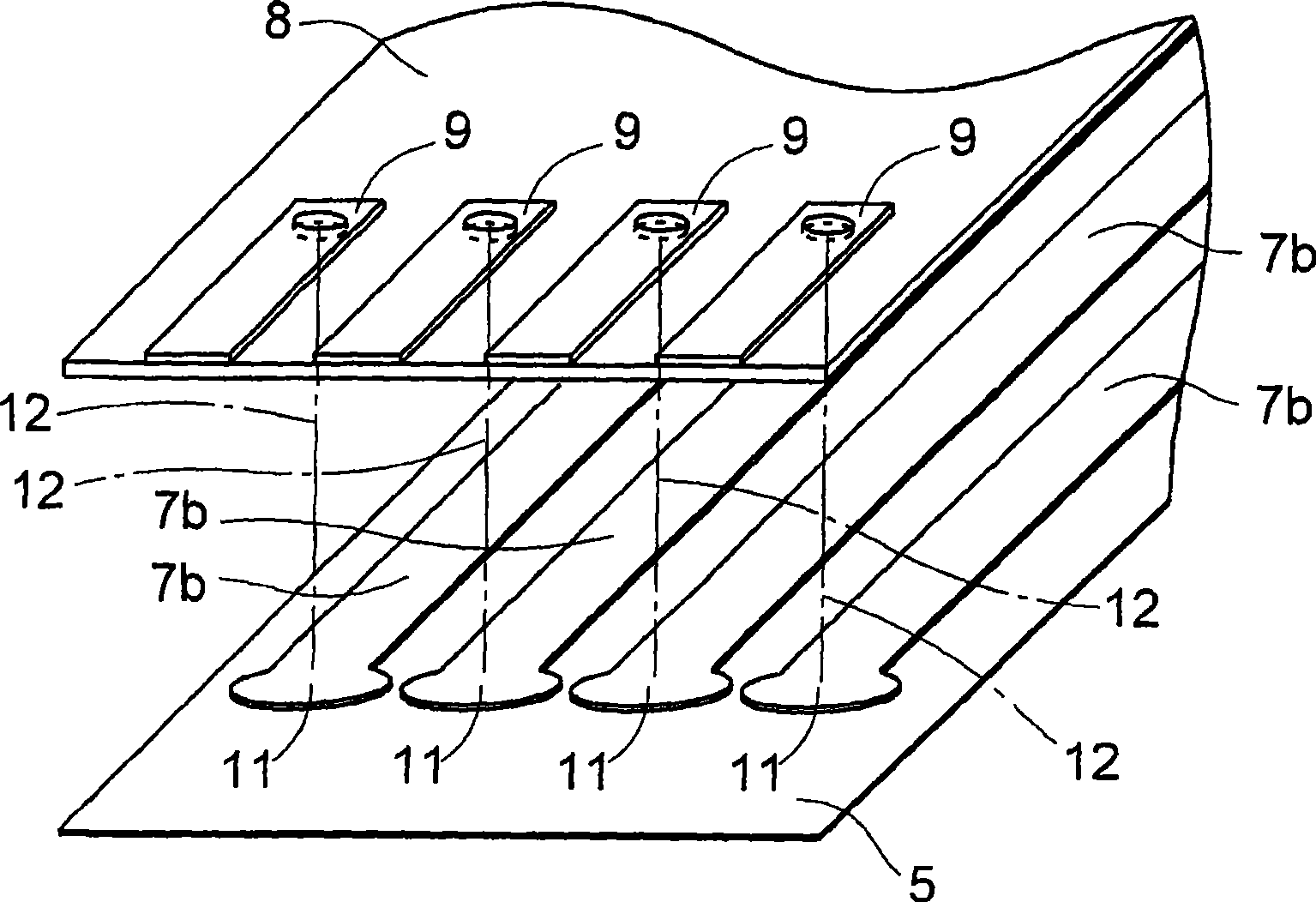

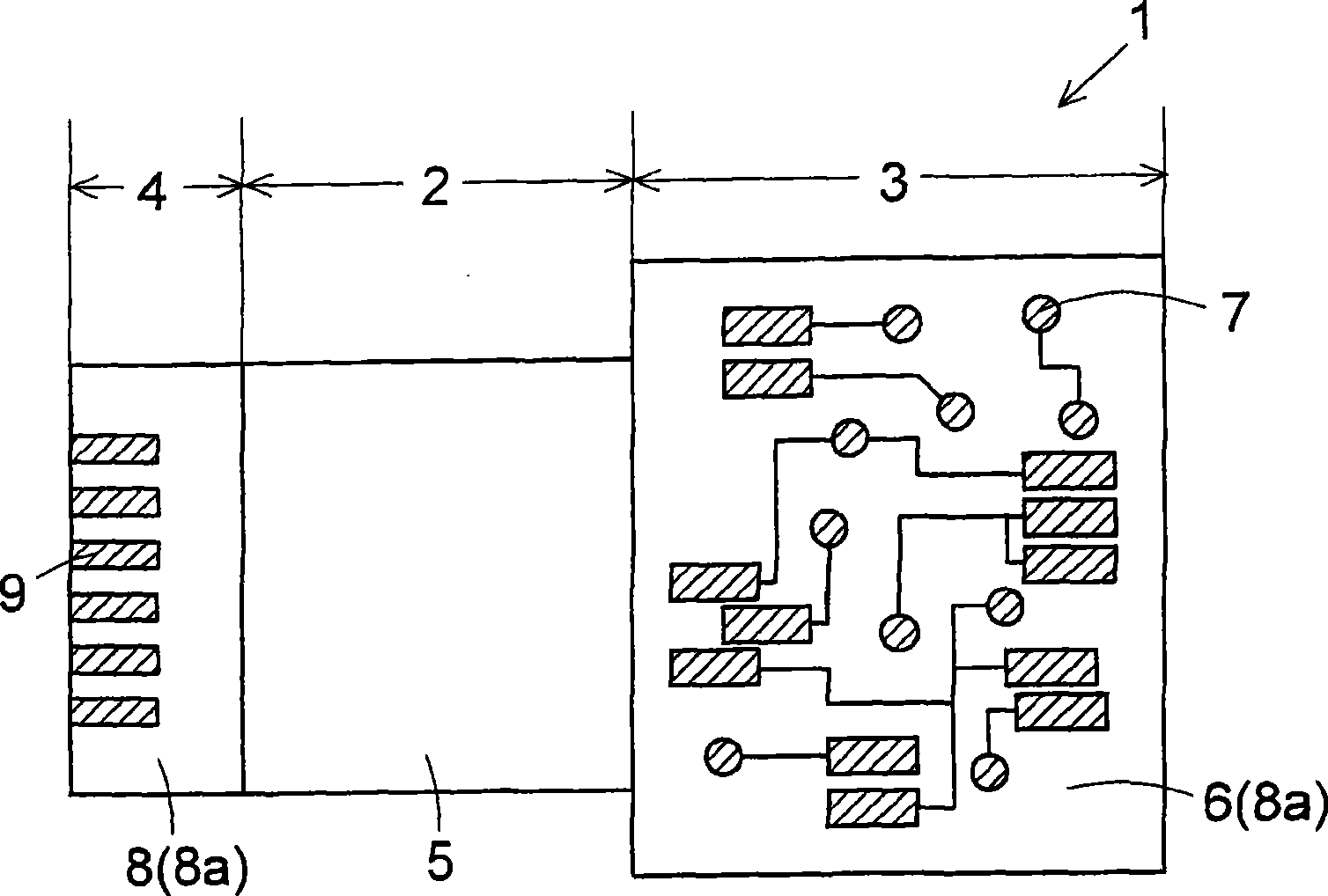

[0059] Figures 1 to 6 The structure of the multilayer printed wiring board according to the first embodiment of the present invention is shown. A multilayer printed wiring board having four conductor layers in total and including a terminal portion having two conductor layers will be described. However, the number of conductor layers formed is not limited to those described above; any number of conductor layers may be formed. The present invention is applicable to any type of multilayer printed wiring board as long as it is provided with a terminal portion.

[0060] The multilayer printed wiring board 1 of the first embodiment is configured as a so-called rigid-flexible wiring board. Specifically, as figure 1 As shown, a multilayer printed wiring board 1 is composed of a flexible portion 2 , a rigid portion 3 and a terminal portion 4 . The flexible portion 2 is configured as a flexible printed wiring board 5 formed of a thin material. The rigid part 3 is formed by formin...

no. 2 approach

[0078] Figure 14 and 15 A multilayer printed wiring board 101 according to a second embodiment of the present invention is shown. For the convenience of description, the same reference numerals are used to denote the Figures 1 to 13 Those of the first embodiment shown have corresponding parts, and descriptions thereof are omitted. A multilayer printed wiring board having six conductor layers in total and including a terminal portion having two conductor layers will be described. However, the number of conductor layers formed is not limited to those described above; any number of conductor layers may be formed. The present invention is applicable to any other type of multilayer printed wiring board as long as it is provided with a terminal portion.

[0079] Such as Figure 14 As shown, the multilayer printed wiring board 101 of the second embodiment is composed of a flexible portion 2 , a rigid portion 3 and a terminal portion 4 . The flexible portion 2 is configured as...

no. 3 approach

[0091] Figure 19 and 20 A multilayer printed wiring board according to a third embodiment of the present invention is shown. For the convenience of description, the same reference numerals are used to denote the Figures 1 to 18 Those parts in the first and second embodiments shown have corresponding parts, and descriptions thereof are omitted.

[0092] Such as Figure 19 As shown, the multilayer printed wiring board 201 of the third embodiment is composed of a flexible portion 2 , a rigid portion 3 , and a terminal portion 4 . The flexible portion 2 is configured as a flexible printed wiring board 5 . The rigid portion 3 is configured by forming a rigid portion 202 and a wiring layer 203 on a part of both surfaces of the flexible printed wiring board 5 . The terminal portion 4 is removed from the flexible printed wiring board 5 by forming an insulating layer 204 on both surfaces of the end portion of the flexible printed wiring board 5 so that a part of the insulating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com