Conductive ball, method of forming electrode of electronic part, electronic part and electronic equipment

A technology of electronic components and electronic equipment, applied in semiconductor/solid-state device components, welding equipment, electrical components, etc., can solve problems such as poor reliability, easy disconnection, and weak mechanical strength of the connection, so as to prevent cracks and Disconnection, prevent bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

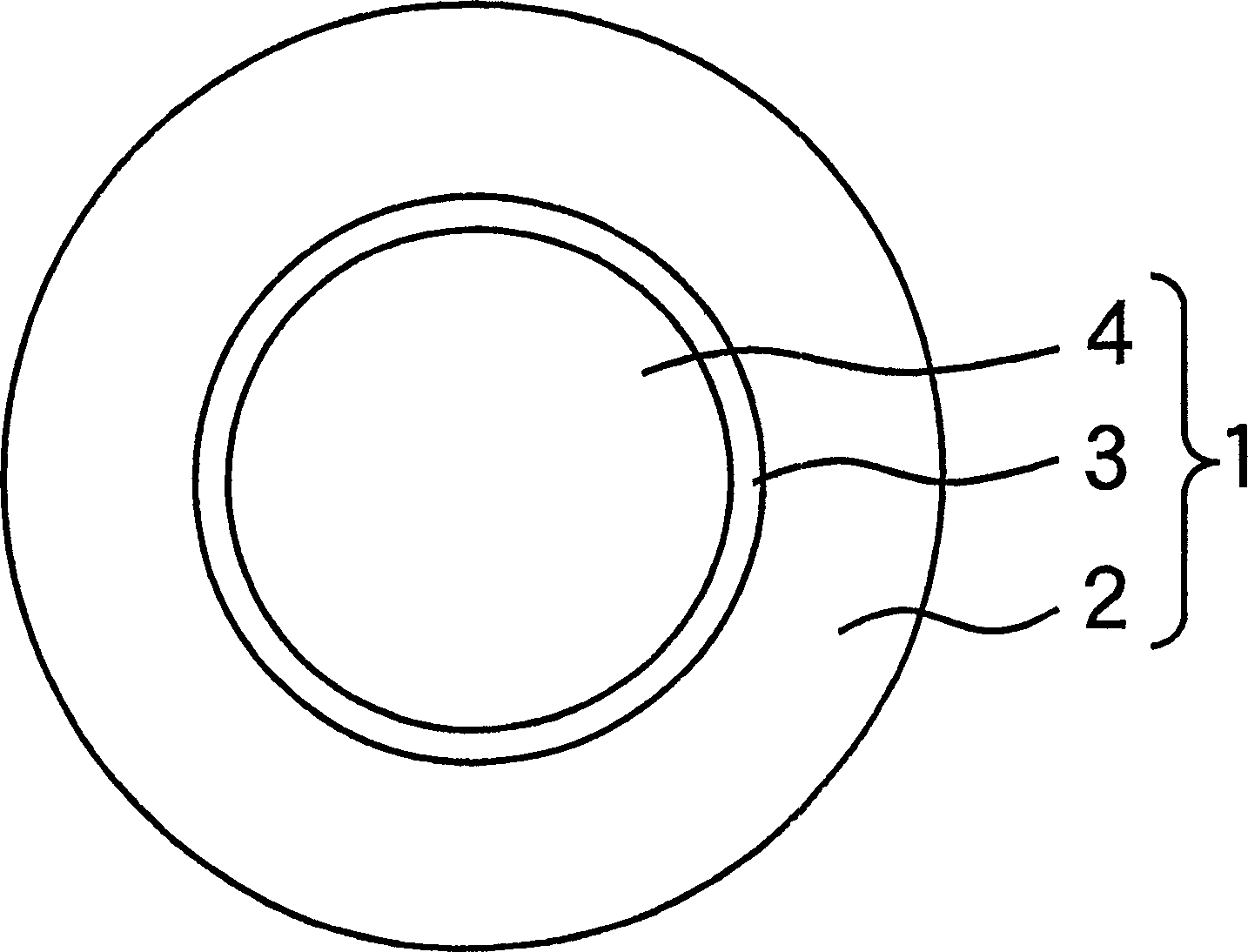

[0092] In this embodiment, an alloy of Sn-5.5Ag composition is used as the solder alloy layer 2 of the above-mentioned conductive ball member 1, and external electrodes are formed on the pads of the electronic component. An alloy layer obtained by sequentially performing Ni plating on Cu and flash Au plating was used on the pad.

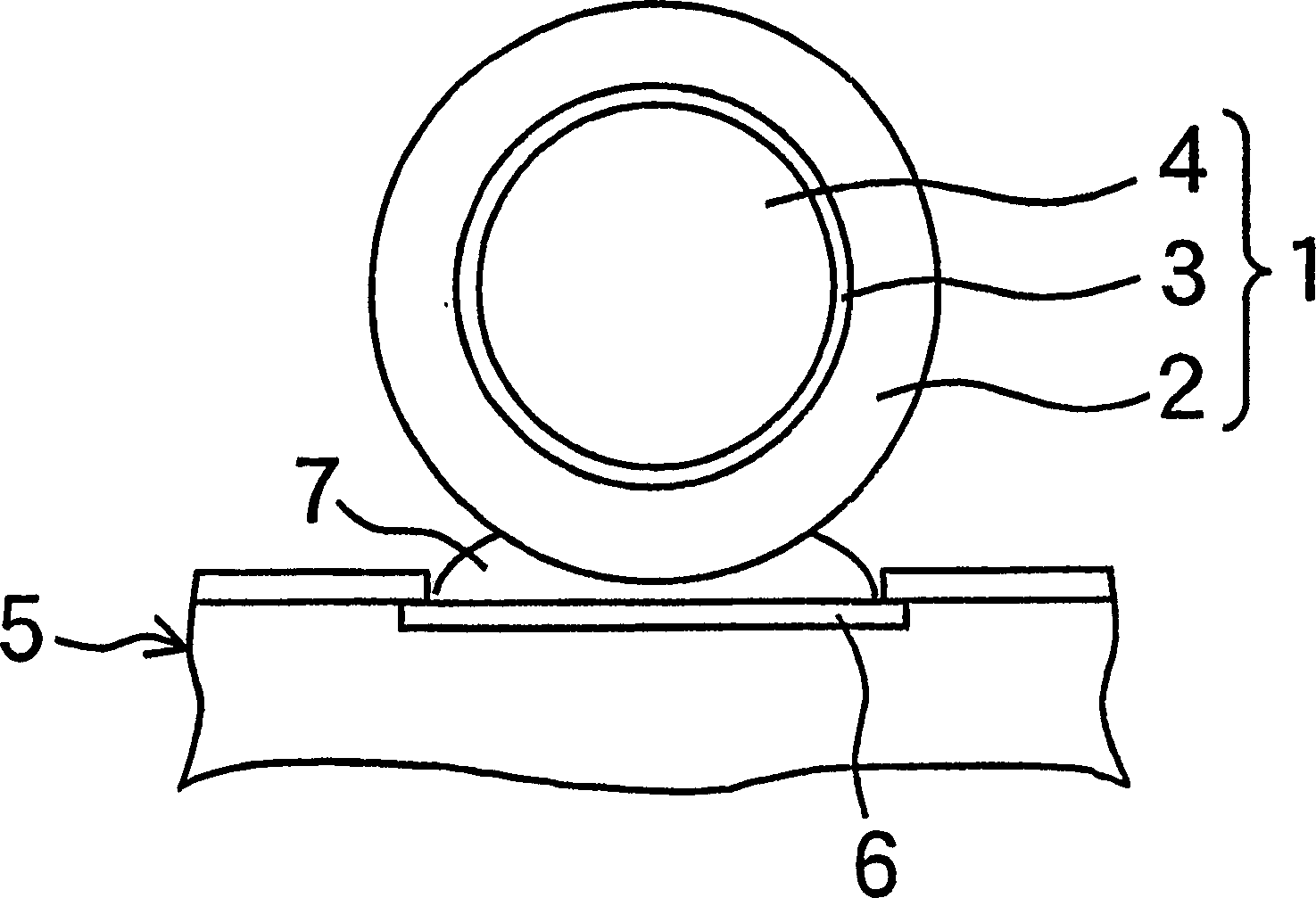

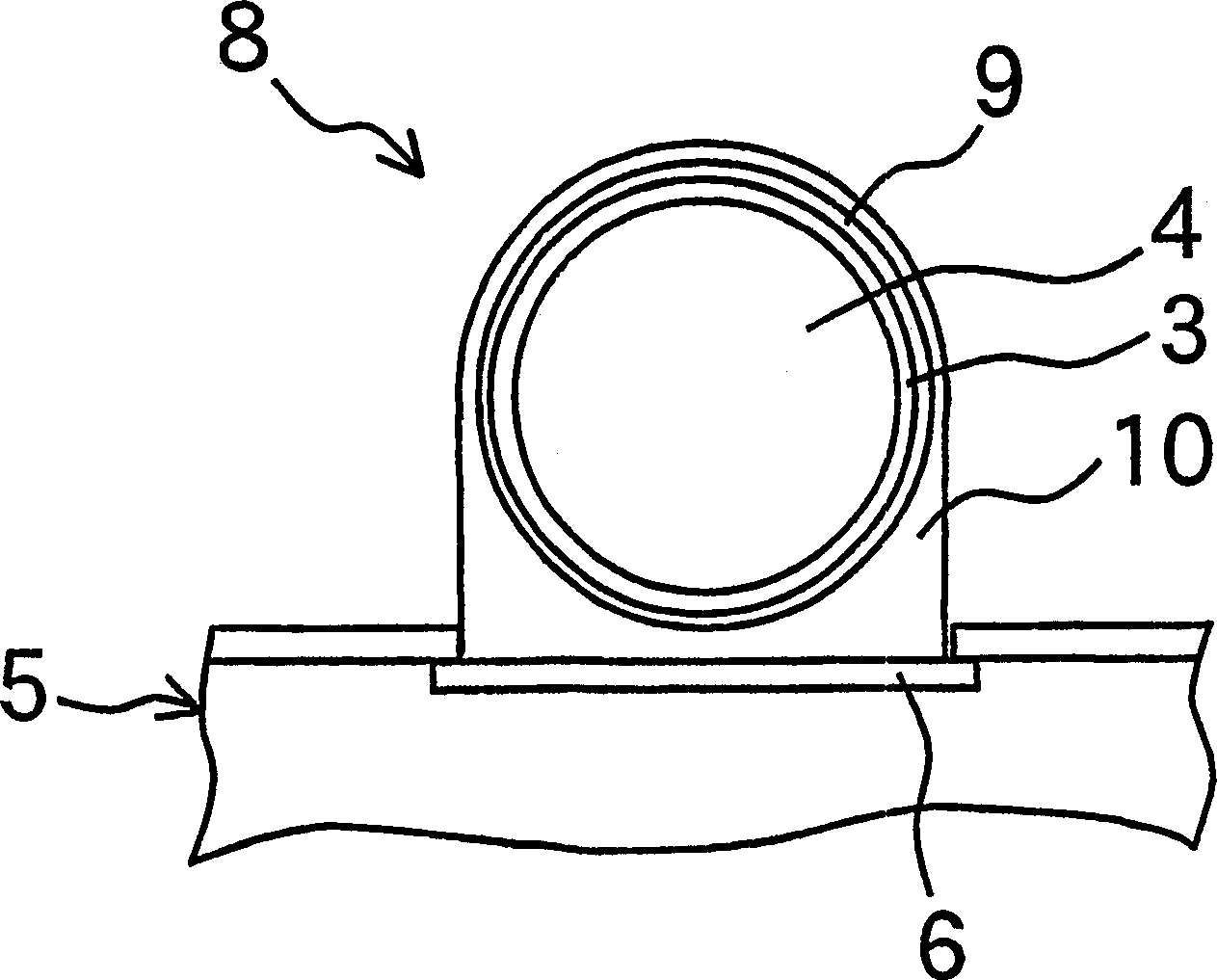

[0093] Figure 2A , B are diagrams showing steps of forming external electrodes on electronic components. exist Figure 2A In , the above-mentioned conductive ball member 1 is disposed on the pad 6 of the above-mentioned electronic component through the solder 7 . In order to remove the oxidized film on the surface of the solder alloy layer 2 or the surface of the pad 6 and maintain appropriate wettability of both, the above-mentioned flux 7 requires an appropriate degree of activity. However, since it becomes a cause of residue after the reflow process, corrosion of metal, etc., it needs to have appropriate removability. In this example, RMA typ...

no. 2 Embodiment

[0128] In this embodiment, a solder alloy having a composition of Sn-3.5Ag is used, and electrodes are formed using a flux different from that in the first embodiment. Since the process of forming electrodes is the same as that of Embodiment 1, detailed description thereof will be omitted. The difference from the first embodiment is that a high-halogen-containing (RA type) flux Deltalux 533 (manufactured by Senju Metal Industries) was used. The flux contains 0.22% Cl. In addition, 240 degreeC peak was used as the reflow temperature condition.

[0129] In the electrode of this example, no exposure of the SnCu layer was observed. This is because the content of the Cl element contained in the flux is increased from 0.04% in the first embodiment to 0.2%, which improves the activity of the flux. This improvement in flux activity can prevent the exposure of the SnCu layer, which is poor in adhesion, even with a solder alloy having a Sn-3.5Ag component. Therefore, even in the cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com