Three-dimensional integrated method of sensor array and signal processing circuits

A signal processing circuit and sensor array technology, which is applied in the process of producing decorative surface effects, decorative arts, gaseous chemical plating, etc. The effect of large-scale array structure and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0065] A three-dimensional integration method of a sensor array and a signal processing circuit includes the following steps:

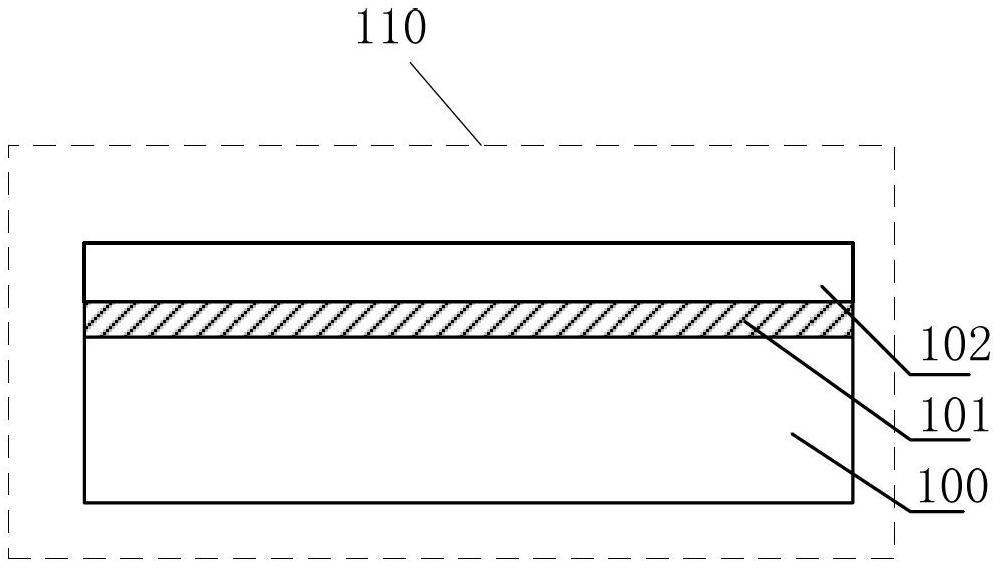

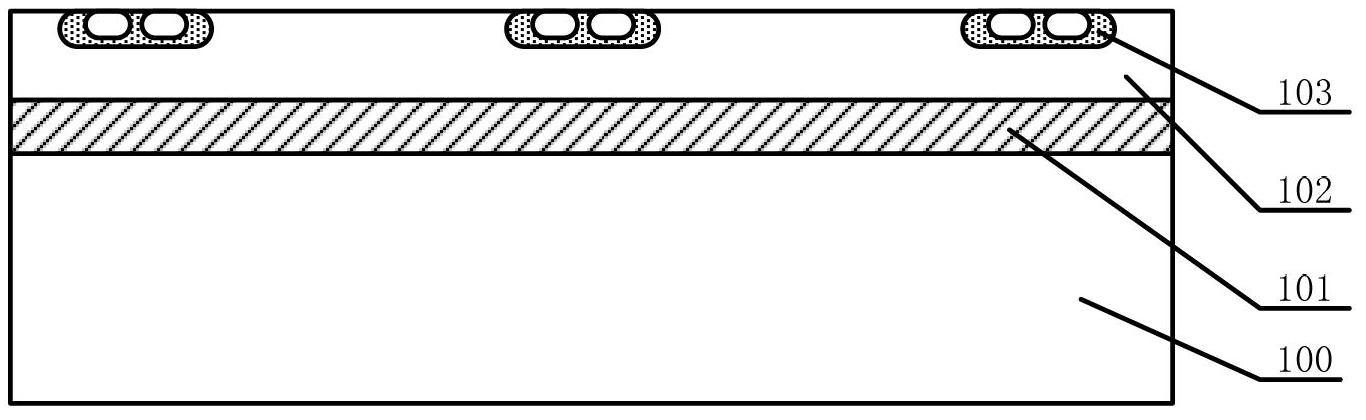

[0066] 1) if Figure 1a and Figure 1b As shown, the sensor 103 is fabricated on the top layer device layer material 102 of the insulating substrate device 110; the sensor structure can be fabricated at the initial stage, or can be manufactured after the top layer device layer material 102 is transferred to the signal processing circuit substrate 200, However, devices that require high-temperature processes, such as resistors, diodes, or transistors manufactured by implantation and annealing processes, need to be manufactured before bonding.

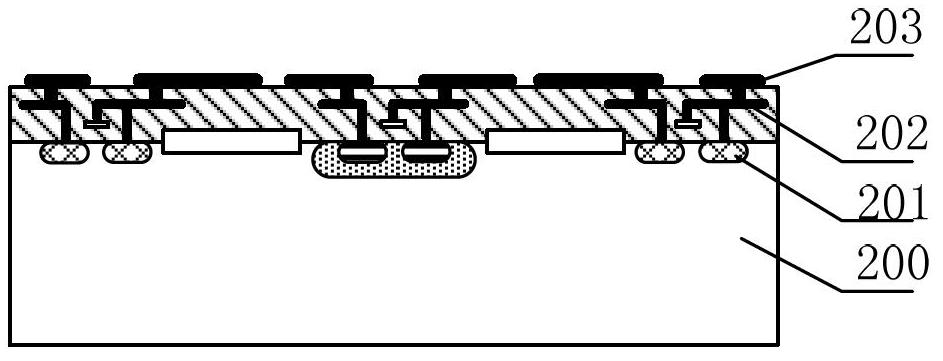

[0067] 2) Manufacturing a signal processing circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com